Weighted girder-less type strong-efficiency energy-saving oil pumping unit

A pumping unit and heavy hammer technology, which is applied in the field of high-efficiency and energy-saving oil pumping units, can solve the problems of high energy consumption and large structure, and achieve the effects of low energy consumption, the most energy consumption, and small impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

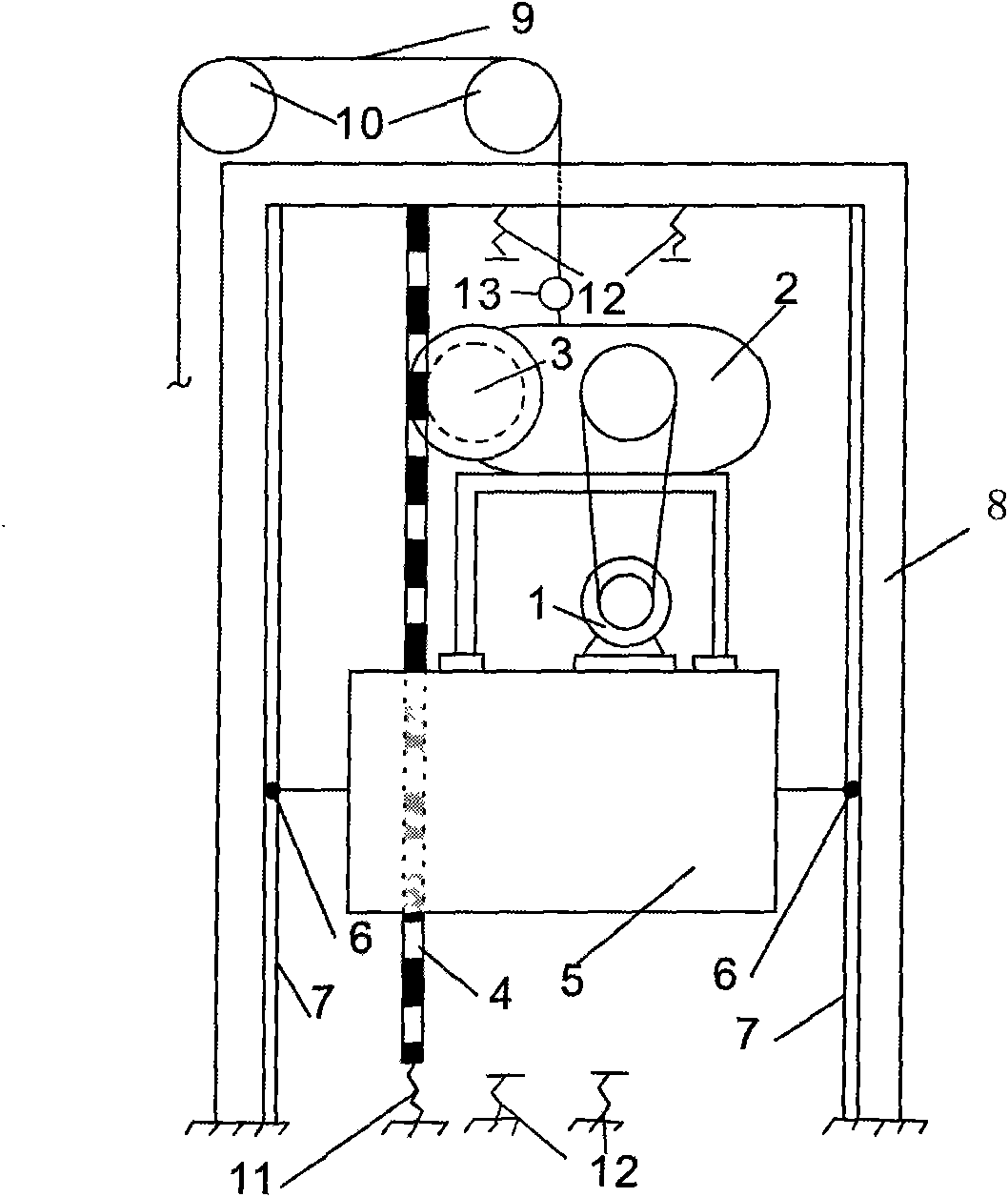

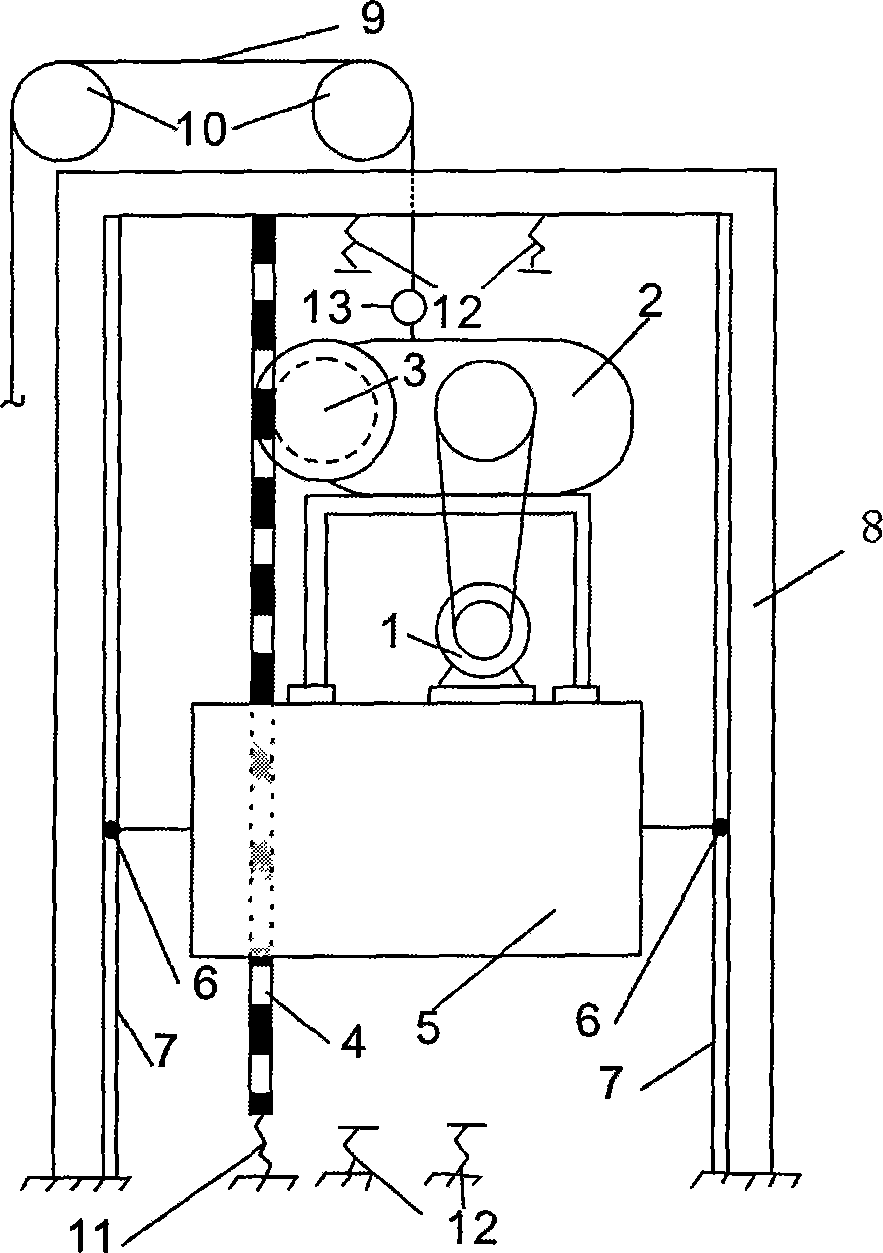

[0019] The lifting system of this embodiment uses a steel frame structure to connect the motor 1, the control box 2, and the weight 5 as a whole, and the rollers 6 are respectively connected on both sides of the weight 5 so that the whole can slide up and down in the guide rail 7.

[0020] The sprocket 3 and the motor 1 are connected by an intermittent mechanism. The chain 4 passes through the weight 5, the upper part is connected to the beam of the bracket 8, and the lower part is directly provided with a tensioner 11, which is fixedly connected to the ground foundation and connected to the sprocket 3. Engaged, the guide rail 7 and the bracket 8 are fixedly connected, the pulley 10 and the beam of the bracket 8 are connected to form a fixed system. The sensor 13 is used to display the force and operating conditions of the system. The lower end is fixedly connected to the cover of the control box 2, and the upper end is connected to the wire rope. 9 is fixedly connected, the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com