Engine test rack device

A technology for testing benches and engines, which is applied in the testing of engines, measuring devices, and testing of machine/structural components. Effects of cleaning and work efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

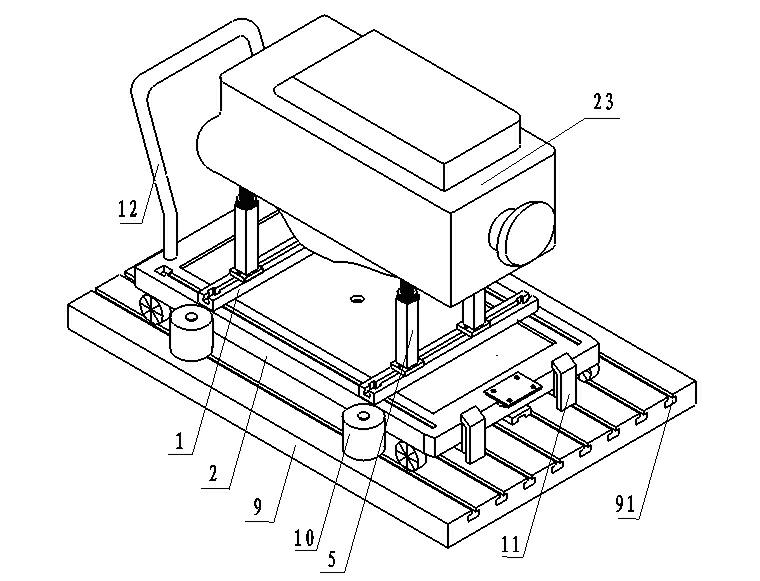

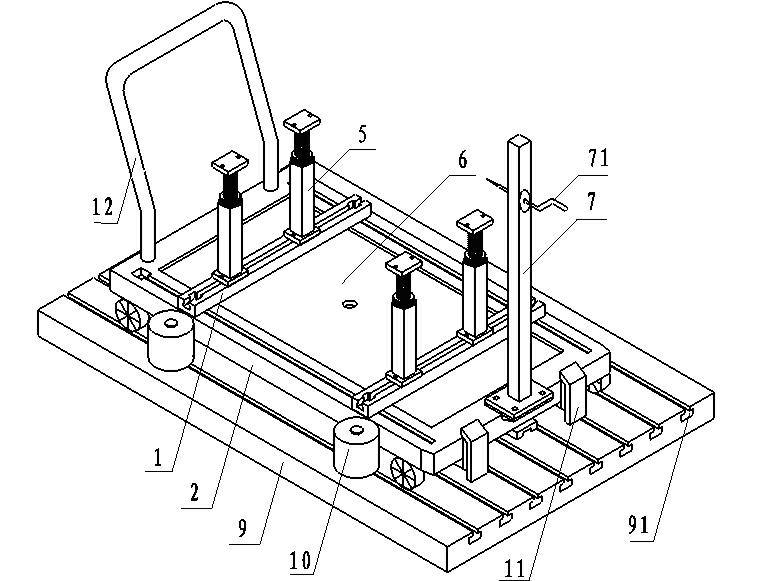

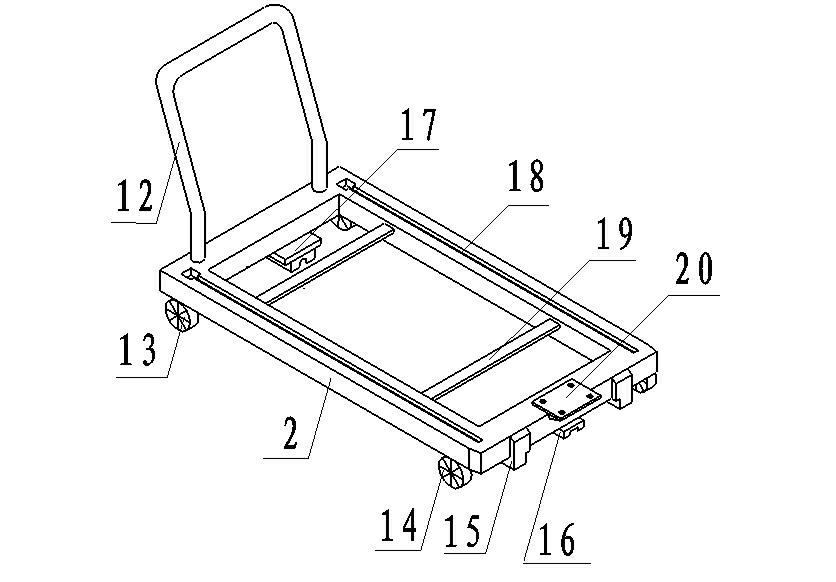

[0027] see Figure 1-Figure 4 , an engine test bench device, including an iron base plate 9, two bench limit blocks 11, four rubber guide wheels 10, a front pad 4, a rear pad 8, a trolley tray body 2 and a trolley pressing mechanism 3 .

[0028] The iron base plate 9 is a rectangular thick steel plate, and its steel plate surface is longitudinally provided with more than four iron base plate T-shaped grooves 91 at equal intervals. The two stand limit blocks 11 are respectively located in the front row of the iron base plate 9 and are fixedly connected to the iron base plate 9 . Two pieces of rubber guide wheels 10 are respectively provided on the top surface of the T-shaped groove 91 of the iron base plate 9 left and right sides, and are fixed on the iron base plate 9 by T-shaped bolts. Its function of stand limit block 11 and rubber guide wheel 10 is to realize the positioning effect of dolly pallet body 2 on iron base plate 9 faces.

[0029] The trolley tray body 2 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com