Device and method for detecting bending strength of structural wood

A testing equipment and bending strength technology, which is applied in the direction of applying stable bending force to test material strength, strength characteristics, measuring devices, etc., can solve the problem that the transmission hydraulic testing machine has low force control accuracy and is not suitable for rapid detection of wood bending. Strength, inability to meet structural beam-column testing requirements, etc., to achieve the effect of simple structure, easy operation, and reduction of measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

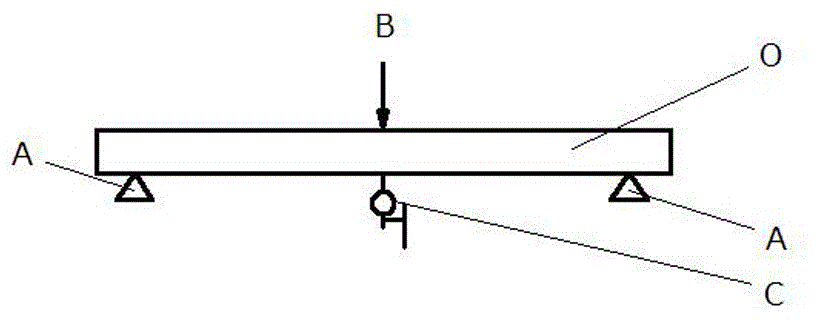

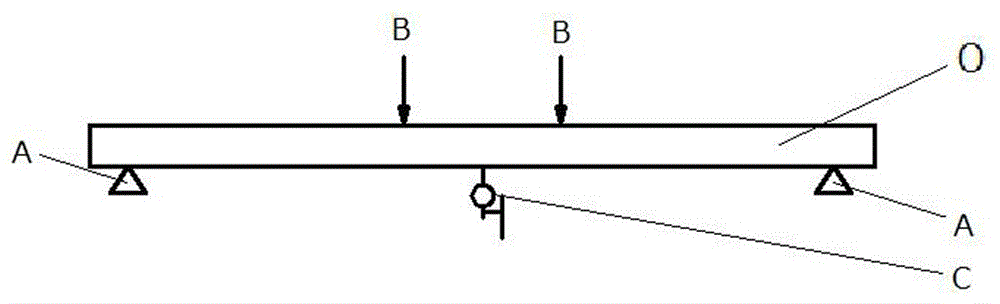

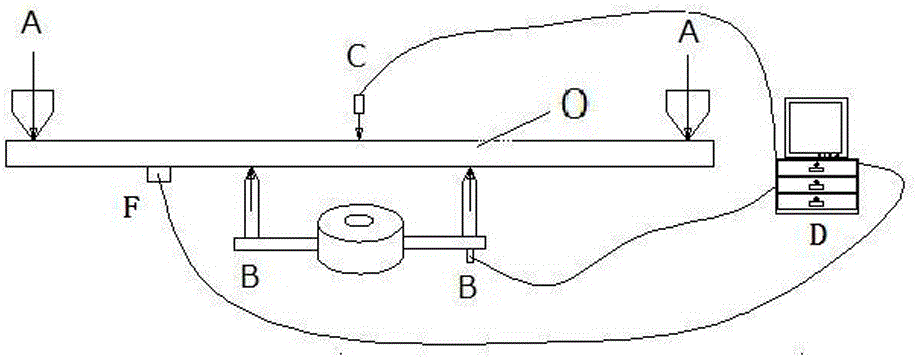

[0051] Such as image 3 Shown is a principle diagram of the method for detecting the bending strength of timber for structures provided by the present invention, that is, the test piece O is supported on two supports A, and the two force-applying frames 3 of the force-applying device apply force from the bottom to the top, and the bottom The data of the load cell B and the displacement sensor C on the top are transmitted to the data processor D, and the required test results can be obtained. The temperature and humidity sensor F can also be set and transmitted to the data processor D, which can be used for The test results are corrected.

[0052] Such as Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 The structural representation of the testing equipment for the bending strength of structural timber provided by the present invention, the testing equipment includes a support 9, on which two slide rails 91 are arranged in parallel in a length direction, the two...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com