Color filter and method for manufacturing same

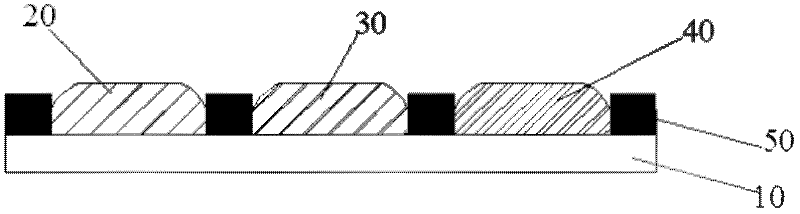

A technology for color filters and manufacturing methods, applied in the direction of filters, optics, optical components, etc., can solve problems such as increased brightness in dark states, abnormal contrast values between bright and dark images of liquid crystal panels, and poor alignment of liquid crystal molecules , to achieve the effect of increasing the contrast value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

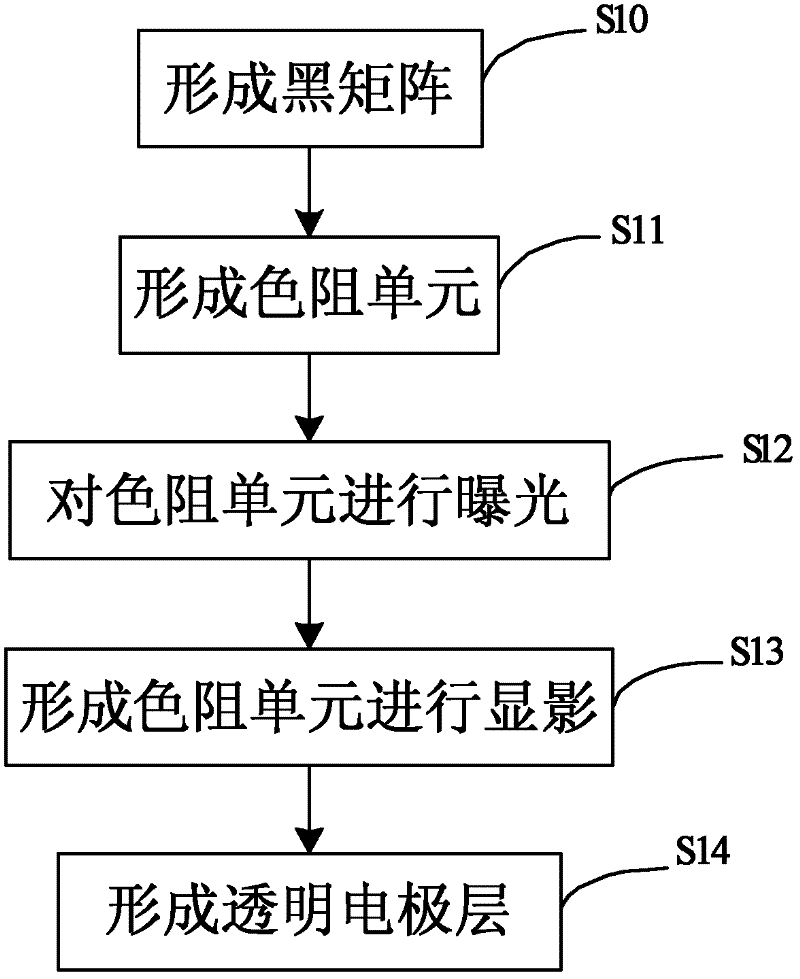

[0035] refer to figure 2 , propose an embodiment of the manufacturing method of the color filter of the present invention, comprising steps:

[0036] S10, forming a black matrix;

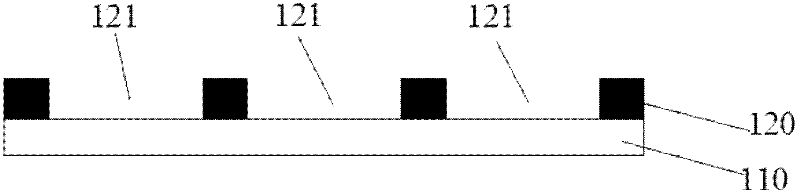

[0037] Firstly, a substrate 110 is provided, which can be made of glass or plastic such as polymethylmethacrylate (PMMA) or polycarbonate (PC). Cleaning the substrate 110 to remove various impurities on the surface, uniformly forming a photoresist layer on the substrate 110, irradiating the photoresist layer with ultraviolet light after passing through the photomask, and then developing the photoresist layer with a developer, so that The photoresist layer forms a black matrix 120, and there are spacers 121 between the black matrix 120, such as image 3 shown. In practical applications, it is not limited to the above method, and other m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com