Secondary 90-degree rotatably-welded polarizing optical fiber resonant cavity

A resonant cavity and polarization-maintaining optical fiber technology, applied in the field of polarizing optical fiber resonant cavity, can solve problems such as the inability to effectively suppress the polarization noise of the resonant fiber optic gyroscope, large polarization interference noise, and suppress polarization noise, etc., to overcome insufficient suppression ability, Effects of suppressing amplitude noise and interference noise and solving polarization noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

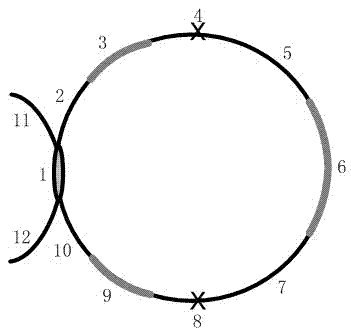

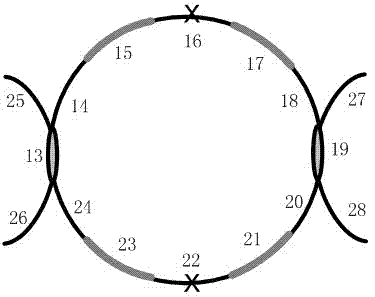

[0020] Such as figure 1 As shown, a polarized reflective fiber resonator with two 90° rotation fusion splicing includes a first polarization-maintaining fiber coupler 1, a first 90° rotation fusion splice point 4, a third pigtail 5, and a second polarizer 6 , the fourth pigtail 7, the second 90 ° rotation fusion splicing point 8; the first polarization maintaining fiber coupler 1 includes the first pigtail 2, the second pigtail 10, the third pigtail 11, the fourth pigtail 12; by The first pigtail 2, the first 90° rotation fusion splice 4, the third pigtail 5, the second polarizer 6, the fourth pigtail 7, the second 90° rotation fusion splice 8 and the second pigtail 10 combined optical fiber ring.

[0021] A first polarizer 3 is connected between the first pigtail 2 in the fiber ring and the first 90° rotation fusion point 4, or the second pigtail 10 in the fiber ring and the second 90° rotation fusion point The third polarizer 9 is connected between 8, or the first polarize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com