A DC power supply with energy closed loop control

A technology of DC power supply and closed-loop control, which is applied in the direction of control/regulation system, conversion of DC power input to DC power output, electrical components, etc. It can solve problems such as poor dynamic performance, reduce complexity, and realize the effect of dynamic adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

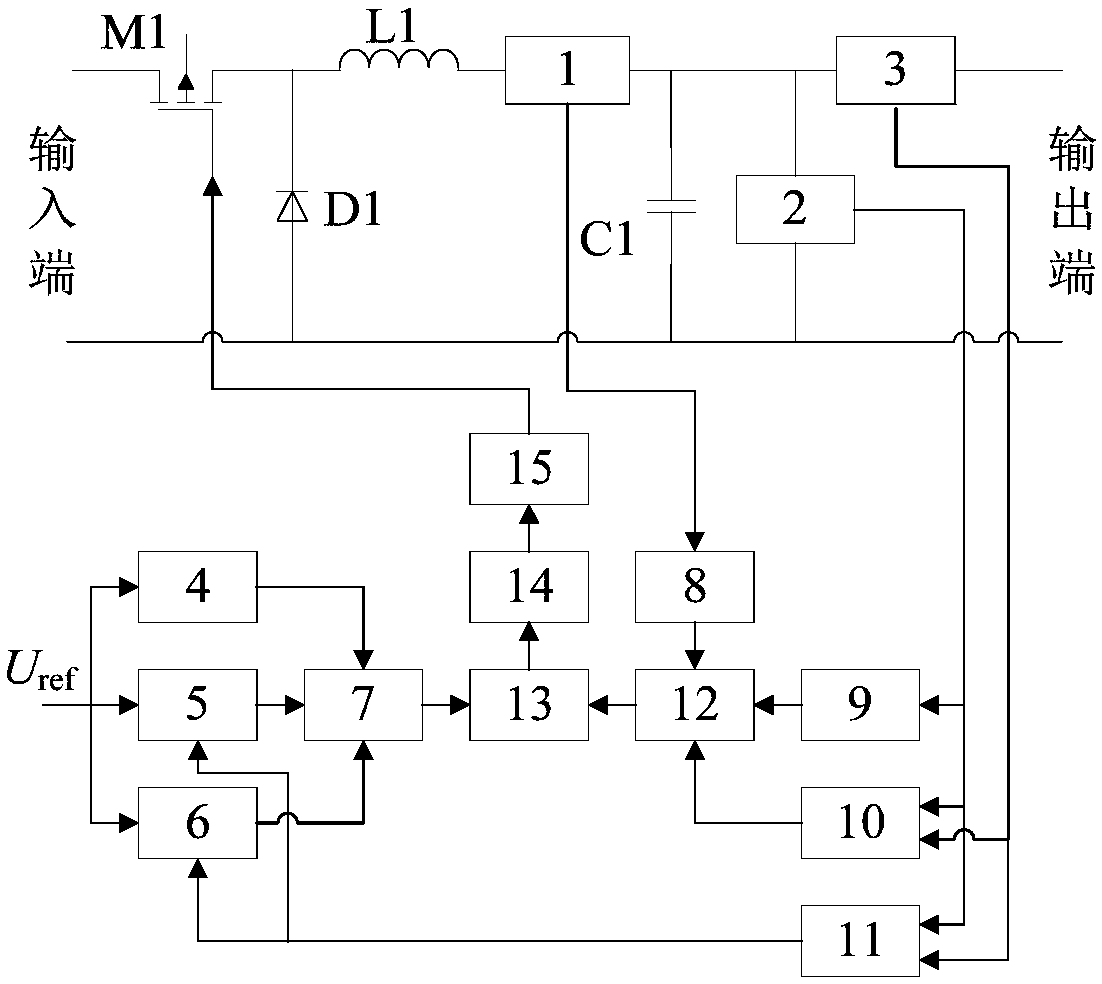

[0030] The main circuit adopts a Buck circuit, and the design and selection methods of the power electronic device M1, inductor L1, capacitor C1, freewheeling diode D1 and other devices are exactly the same as those of the existing standard Buck circuit;

[0031] The inductor current detection circuit 1 and the output current detection circuit 3 can be designed and implemented with reference to various existing circuits with current detection and signal transmission functions, for example, Hall-type current sensors can be used supplemented by corresponding signal processing circuits.

[0032] The capacitive voltage detection circuit 2 can be designed and implemented with reference to various existing circuits with voltage detection and signal transmission functions, for example, a Hall-type voltage sensor can be used supplemented by a corresponding signal processing circuit.

[0033] The expected capacitor energy storage calculation circuit 4 is realized by a circuit capable of...

Embodiment approach 2

[0046] The main circuit adopts other topology forms of Buck circuit, or other forms of DC / DC conversion circuits.

[0047] When the number of capacitive and inductive devices in the main circuit, the placement position and figure 1 When the main circuits shown are different, each capacitor needs to have a corresponding terminal voltage detection circuit, as well as a corresponding expected energy storage calculation circuit and an actual energy storage calculation circuit; each inductor needs a corresponding current detection circuit, and a corresponding The expected energy storage calculation circuit and the actual energy storage calculation circuit; the number and operation rules of the input channels of the expected total energy calculation circuit 7 and the actual total energy calculation circuit 12 also need to be adjusted accordingly.

[0048] Other design methods are the same as the first implementation method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com