Sand mill with double cooling systems

A sand mill, double cooling technology, applied in the direction of grain processing, etc., can solve the problems of unqualified active ingredients, affecting the grinding quality, material cooling, etc., to protect the grinding stability and quality, protect the stability, and slow down the flow speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

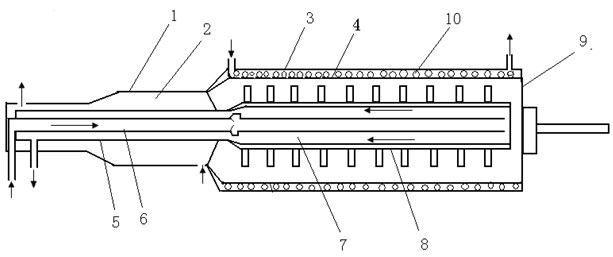

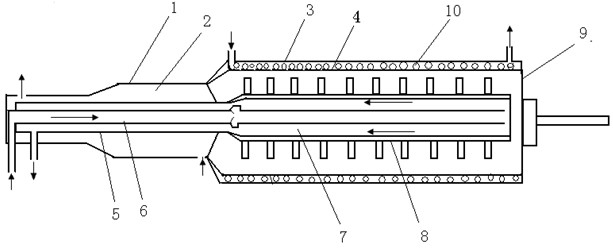

[0028] Such as figure 1 The sand mill with double cooling system shown includes a bearing housing 1, a grinding cylinder 9 and a grinding drum 8 disposed in the inner cavity of the grinding cylinder 9, a main shaft 5 disposed in the bearing housing 1 and the grinding drum 8 Fixed connection, the grinding cylinder 9 is composed of an outer sleeve 3 and an inner sleeve 4, and the interlayer between the outer sleeve 3 and the inner sleeve 4 is provided with a spiral tubular cooling water pipe 10 made of red copper, and the cooling water pipe 10 is arranged in the inner Circulating water cooling is carried out on the outer peripheral surface of the sleeve 4 . The main shaft 5 and the grinding drum 8 are internally provided with a water delivery pipe 6, the outer wall of the water delivery pipe 6 forms a water delivery sleeve 7 with the main shaft 5 and the inner wall of the grinding drum 8, and the inner wall of the grinding drum is provided with a spiral water tank; The water de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com