Hydraulic synchronous driving system for adjusting unbalanced load based on proportional valve controlled energy accumulator

A technology of hydraulic synchronization and drive system, applied in the direction of fluid pressure actuating device, servo motor, mechanical equipment, etc., can solve the problems of inability to ensure load balance, inability to achieve speed synchronization, inability to synchronize accuracy, etc., to eliminate adverse effects, eliminate Synchronization error, uniform coordination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

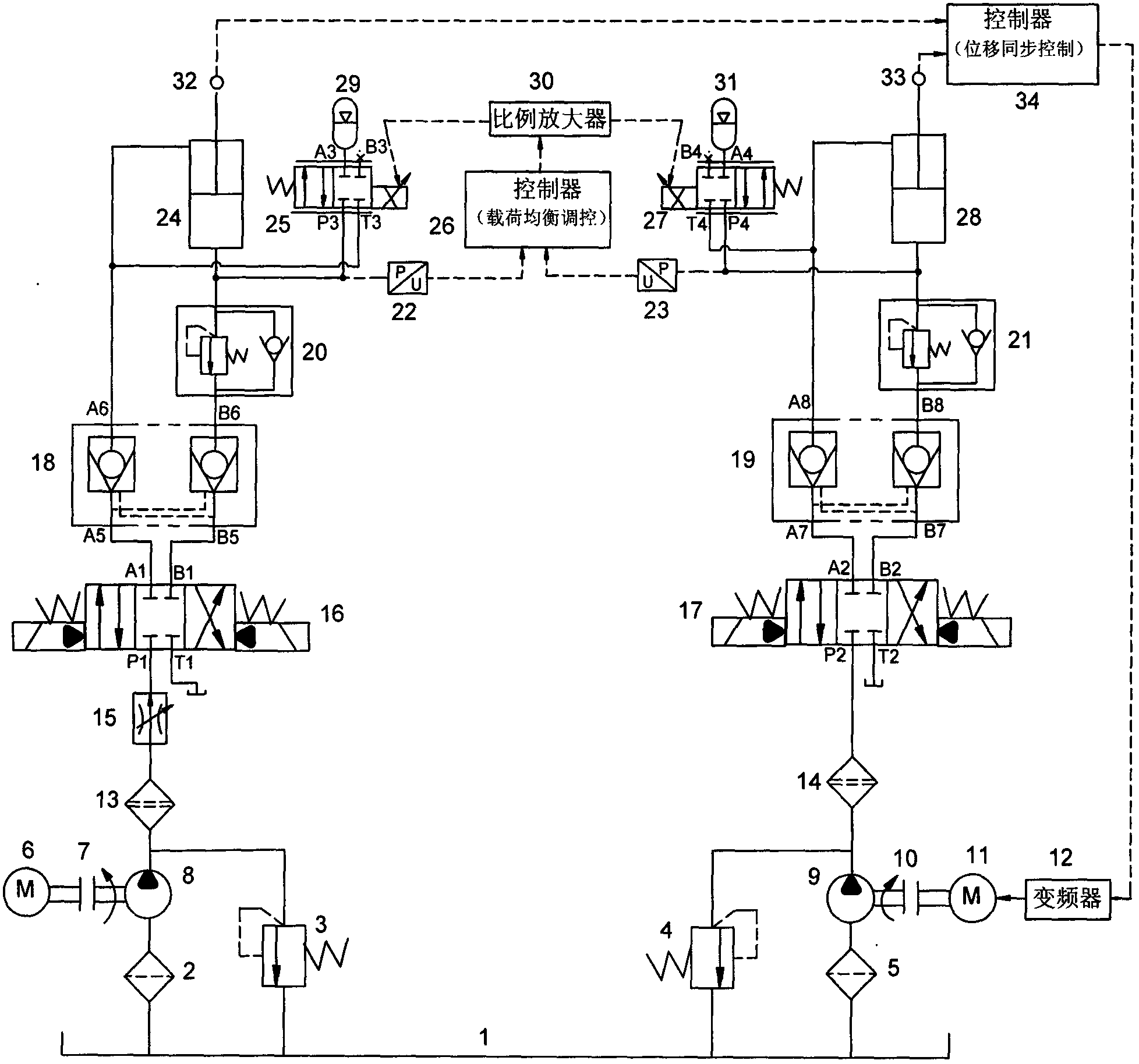

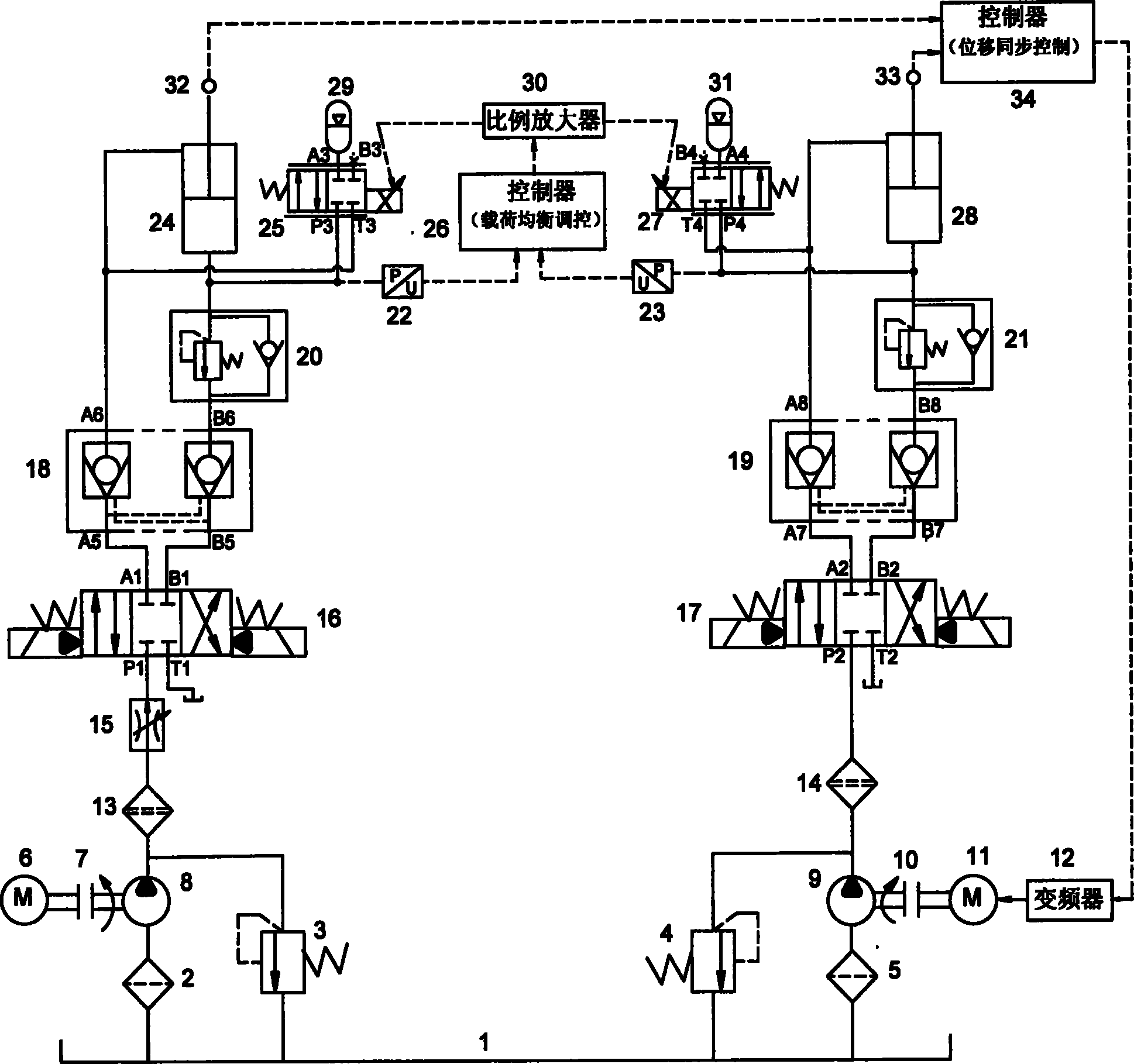

[0012] As shown in the accompanying drawings, the present invention includes a hydraulic transmission circuit and an electro-hydraulic control system. The hydraulic transmission circuit includes a fuel tank 1, two oil suction filters 2, 5, two overflow valves 3, 4, two motors 6, 11, two shaft couplings 7, 10, two quantitative pumps 8, 9 , two high-pressure filters 13, 14, speed control valve 15, two three-position four-way electro-hydraulic reversing valves 16, 17, two hydraulic locks 18, 19, two balance valves 20, 21, two hydraulic cylinders 24 , 28, two two-position four-way proportional reversing valves 25,27, two accumulators 29,31. The first motor 6 is connected with the first quantitative pump 8 through the first coupling 7; the oil inlet of the first oil suction filter 2 is connected with the oil tank 1, and the oil outlet is connected with the inlet of the first quantitative pump 8 Oil port; the oil outlet of the first quantitative pump 8 is respectively connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com