On-line measuring method and device for outer diameter and ovality of large-diameter steel pipe end

A measuring device and large-caliber technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as high operational requirements, difficulty in overcoming, and measurement errors, and achieve high measurement accuracy, enhanced stability, and flexible mechanisms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

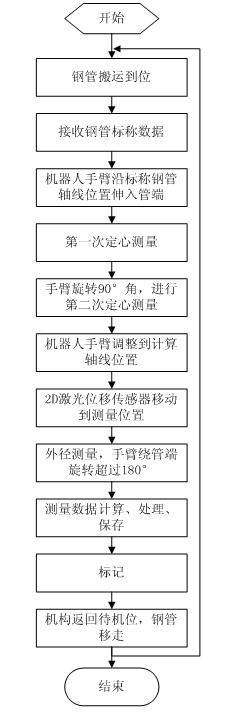

[0028] like figure 2 As shown, a method for online measurement of the outer diameter and ellipticity of a large-diameter steel pipe end includes the following steps:

[0029] Step 1. Receive the nominal data of the steel pipe to be tested, and determine the nominal axis position of the steel pipe to be tested;

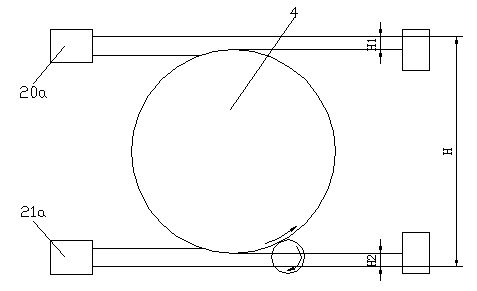

[0030] Step 2. Axis center detection. Select a pair of axial laser displacement sensors, set the probes of the two axial laser displacement sensors symmetrically and back, and extend from the nominal axis position into the steel pipe to be tested. Measure the length of any two chords to the section, and then draw the perpendicular of the two chords, the intersection of the two perpendiculars is the axis of the section;

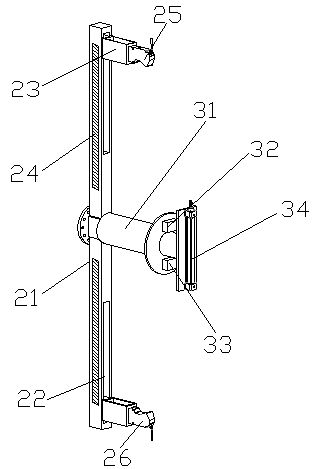

[0031] Step 3. Select a pair of outer diameter laser displacement sensors, set the probes of the two outer diameter laser displacement sensors symmetrically opposite each other, move the two outer diameter laser displacement sensors to the measuremen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com