Stable cold field emission electron source

An electron source, field emission technology, applied in the field of electron sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

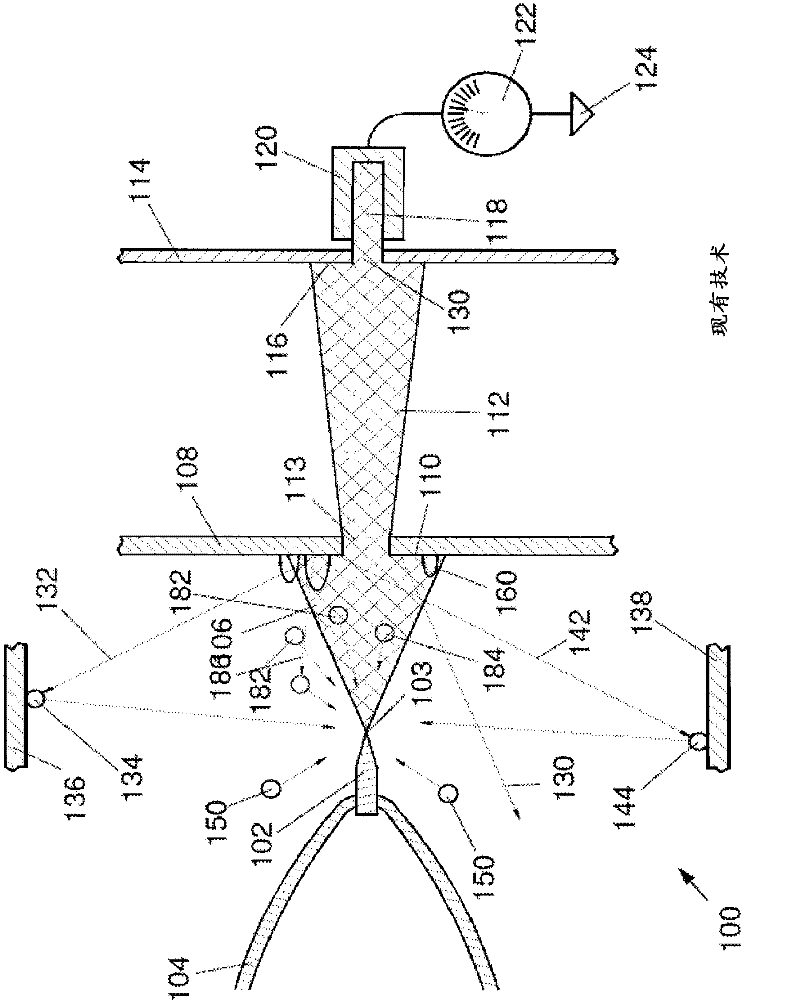

[0042] Figure 7is a schematic diagram of a portion of a cold field emitter electron source showing a first embodiment 700 of the emitter tip region. The emitter wire 702 has a sharpened end 703 that emits electrons 710 under the influence of a high electric field at the tip 703 caused by a high voltage applied between the emitter tip 703 and the extractor 708 . A volume enclosing tip 703 is formed between the emitter enclosing electrode (EEE) 752 and the inner surface of the extractor 708 . Cleaning filament 730 is shown between EEE 752 and extractor 708 . An important consideration in the design of the source region of this first embodiment is the aspect ratio between the EEE 752 and the outer radius of the extractor 708 and the gap separating the EEE 752 from the inner surface of the extractor 708 . A larger aspect ratio prevents more backscattered electrons generated from the inner surface of the extractor 708 from hitting other (possibly unclean) surfaces in the gun, su...

no. 3 example

[0046] Figure 9 is a schematic diagram of a portion of the cold field emitter electron source of the present invention showing a third embodiment 900 of the emitter tip region. The emitter wire 902 has a sharpened end 903 that emits electrons 910 under the influence of a high electric field at the tip 903 caused by a high voltage applied between the emitter tip 903 and the extractor 908 . Cleaning filament 930 is shown between EEE 952 and extractor 908 . A volume enclosing tip 903 is formed between the emitter enclosing electrode (EEE) 952 and the inner surface of the extractor 908 . For this embodiment, EEE 952 has an outer shield ring 990 that prevents the escape of backscattered electrons 971 emitted from region 904 on extractor 908 and backscattered electrons 972 reflected from EEE 952, as the picture shows. The benefit of the improved BSE seal in this third embodiment has to be balanced against a slightly reduced pump speed from the source tip region. An additional b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com