Control device

A control device and melt spinning technology, applied in general control system, program control, computer control, etc., can solve problems such as dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

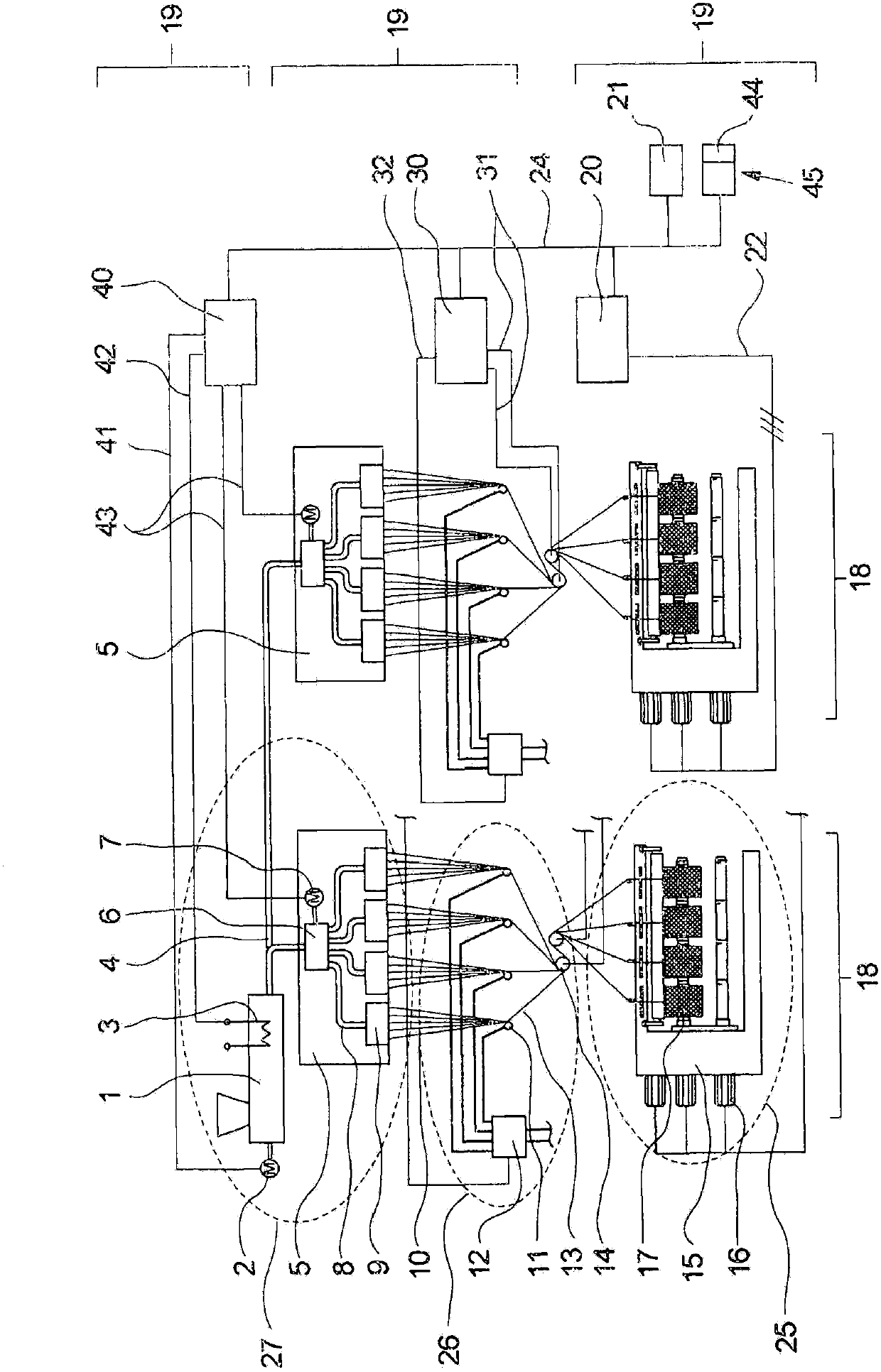

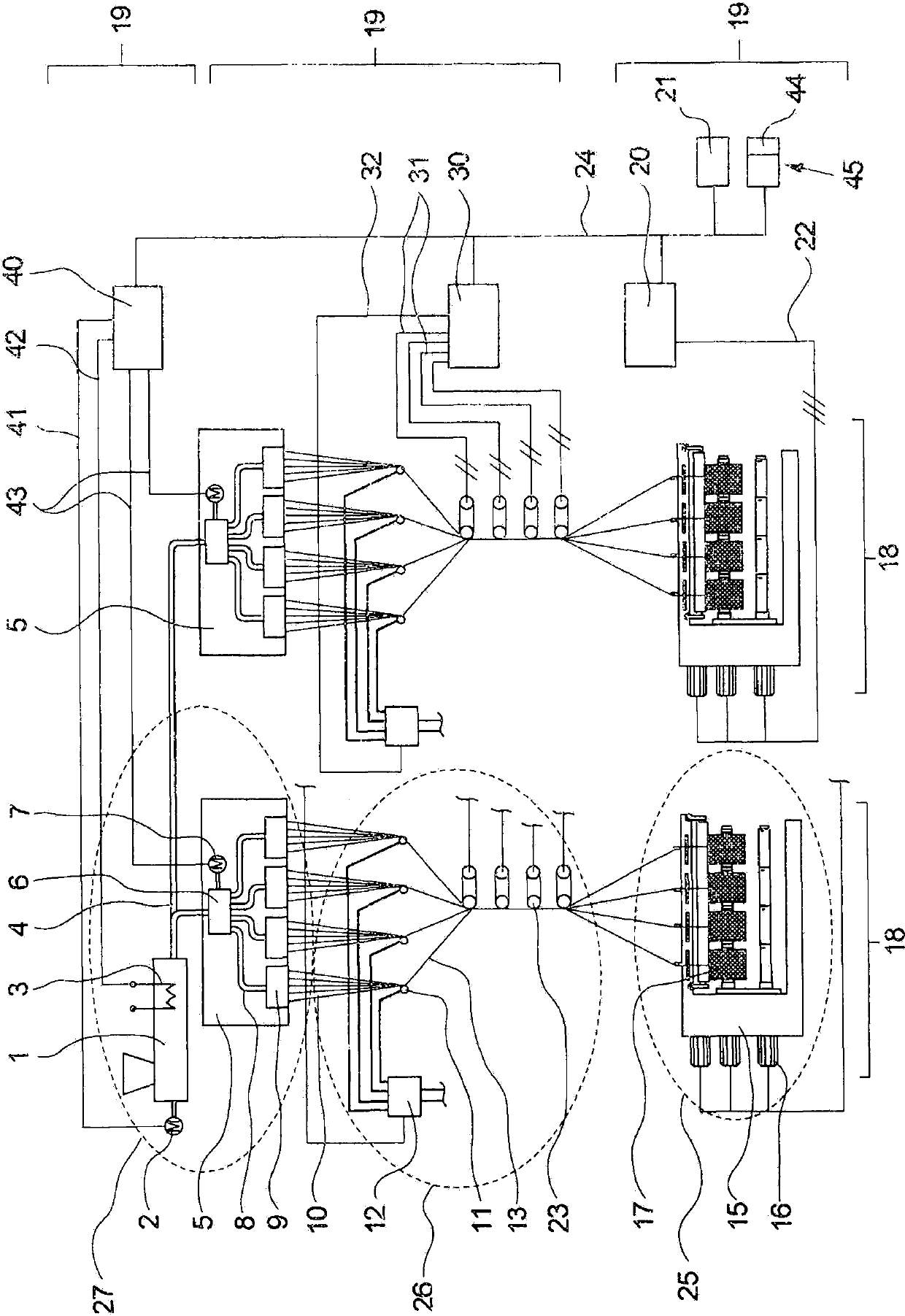

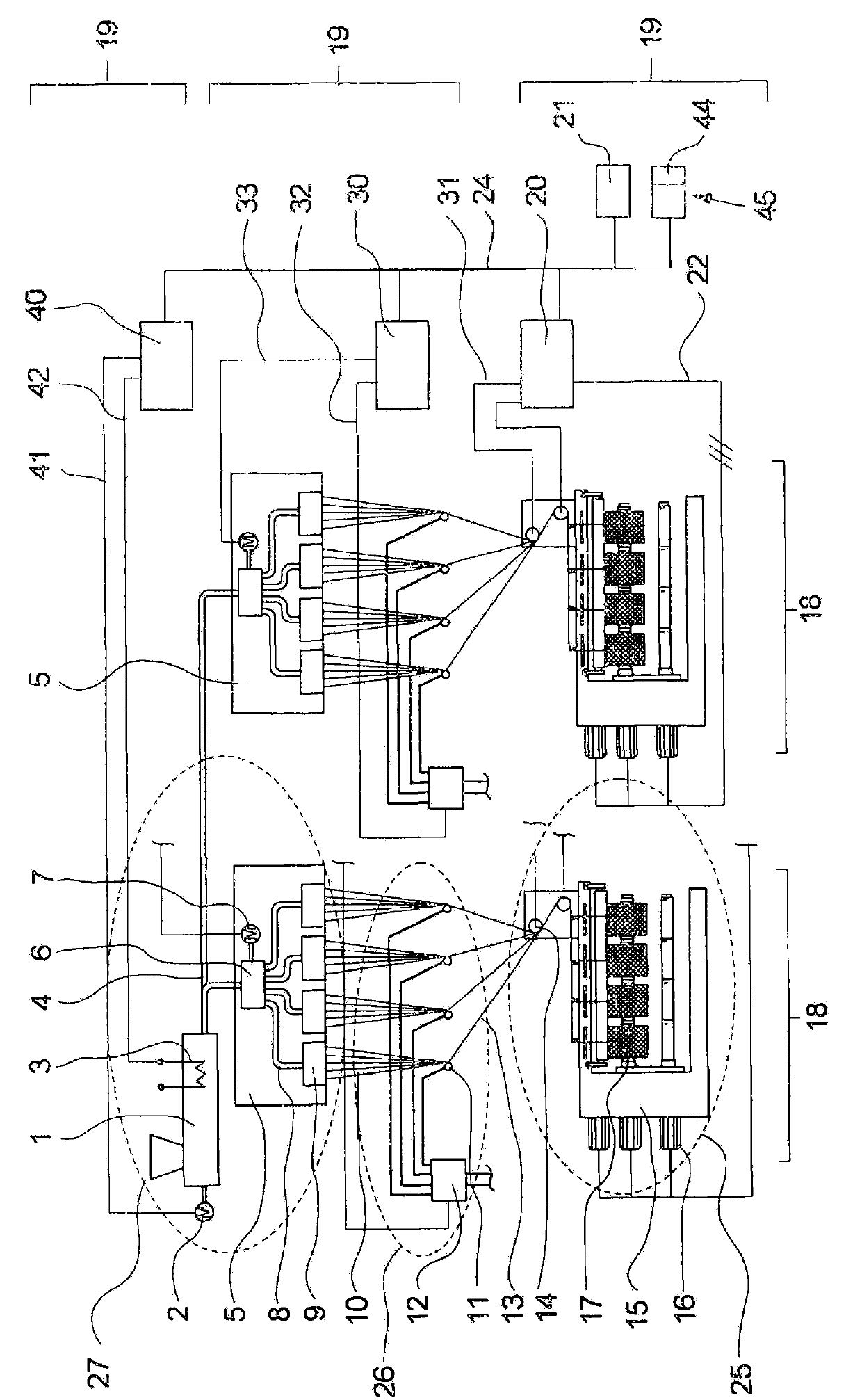

[0026] figure 1 A control device according to the invention for controlling a melt spinning machine is shown.

[0027] In order to produce a plurality of synthetic threads, a plurality of different working units are arranged successively in the material flow in the melt spinning machine in order to produce a plurality of synthetic threads from the polymer, for example in pellet form, in a plurality of working steps. In the illustrated embodiment of the melt spinning machine, the working mechanism chain starts with extruder 1 . The polymer material predetermined in the form of pellets is melted into a polymer melt by the extruder 1, which is driven by an extruder and distributed to several spin beams 5 via a plurality of melt lines The device 2 is driven and heated by means of the extruder heating device 3 . For the sake of clarity, only two spin beams 5 are described here. Usually more spin beams 5 are used. It is likewise also possible to use a plurality of extruders 1 or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com