Control device for induction heating device and method for controlling induction heating system and induction heating device

An induction heating device and control device technology, applied in induction heating control, induction heating device, induction heating, etc., can solve problems such as uneven temperature distribution of conductor plates, achieve simple and reliable induction heating control, and prevent temperature distribution from becoming uneven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach )

[0052] First, a first embodiment of the present invention will be described.

[0053]

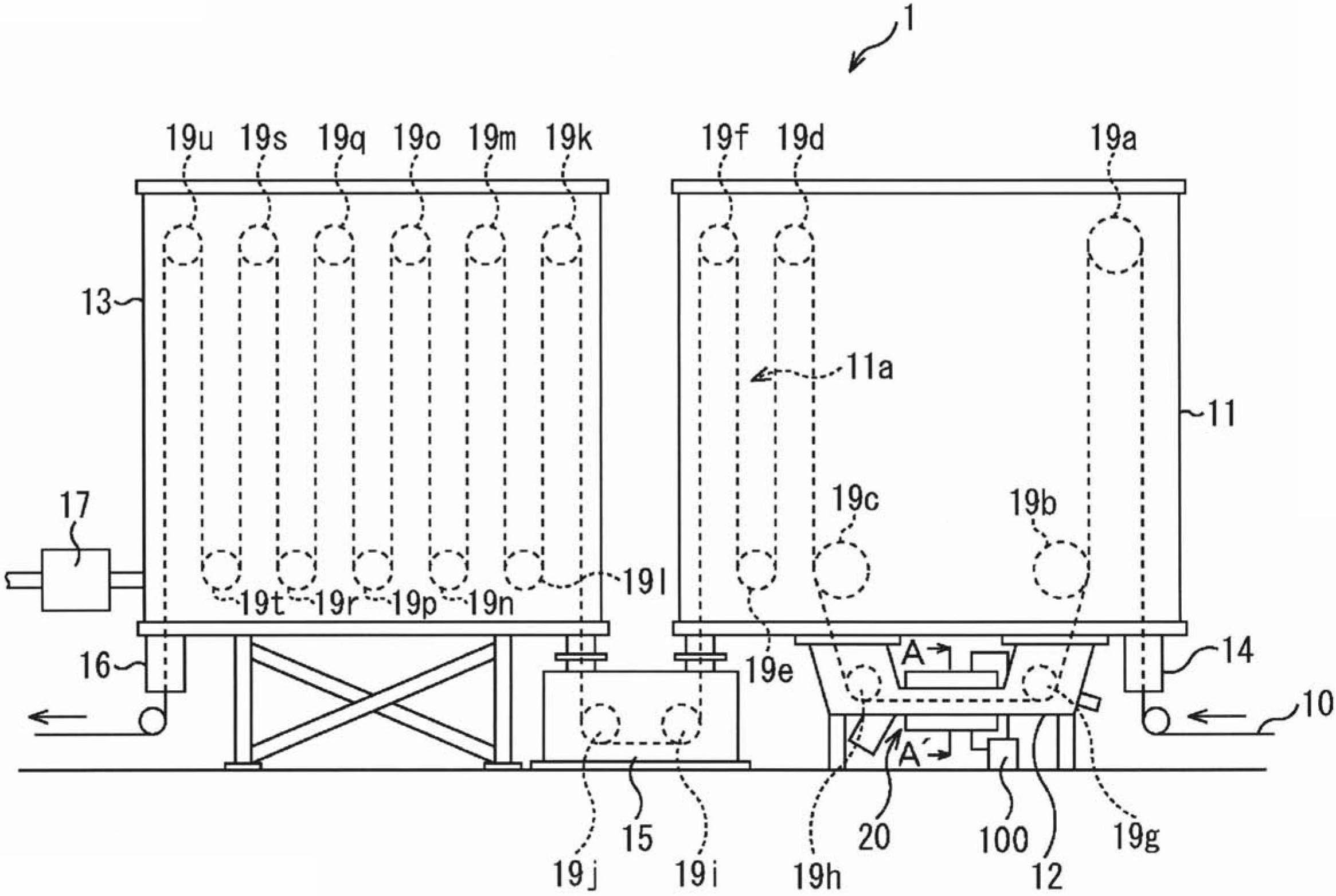

[0054] figure 1 It is a side view showing an example of a schematic configuration of a continuous annealing line for steel sheets.

[0055] exist figure 1 Among them, the continuous annealing line 1 includes a first container 11, a second container 12, a third container 13, a first seal roll assembly 14, a transfer device 15, a second seal roll assembly 16, a gas supply device 17, and rolls 19a- 19u, the induction heating device 20 and the control device 100 of the induction heating device. In addition, an induction heating system is constituted by the induction heating device 20 and the control device 100 of the induction heating device.

[0056] The first seal roll assembly 14 conveys the strip-shaped steel plate 10 into the first container 11 while isolating the first container 11 from the outside air. The strip-shaped steel plate 10 conveyed into the first container 11 by the firs...

no. 2 Embodiment approach )

[0140] Next, a second embodiment of the present invention will be described. In the aforementioned first embodiment, the alternating current I L Directly from the MERS 130 to the induction heating device 20 . In contrast, in this embodiment, the alternating current I L Flows from the MERS 130 to the induction heating device 20 via the transformer. Thus, in the configuration of the present embodiment, a transformer is added to the configuration of the first embodiment described above. Therefore, in the description of this embodiment, regarding the same parts as those of the first embodiment described above, Figure 1 ~ Figure 6B The attached symbols are the same symbols and detailed explanations are omitted.

[0141] Figure 7 It is a figure which shows an example of the structure of the control apparatus 200 of an induction heating apparatus.

[0142] Such as Figure 7 As shown, the control device 200 of this embodiment, in Figure 4 In the control device 100 of the fi...

no. 3 Embodiment approach )

[0147] Next, a third embodiment of the present invention will be described. In the aforementioned first and second embodiments, flat plates are used as the shielding plates 31 a to 31 d provided in the induction heating device 20 . On the other hand, in this embodiment, a recess is provided on the shielding plate provided on the induction heating device 20 . In this manner, the present embodiment differs from the first and second embodiments described above in part of the configuration of the shielding plate. Therefore, in the description of this embodiment, regarding the same parts as those of the above-mentioned first and second embodiments, the following description will be added. Figure 1 to Figure 7 The attached symbols are the same symbols and detailed explanations are omitted.

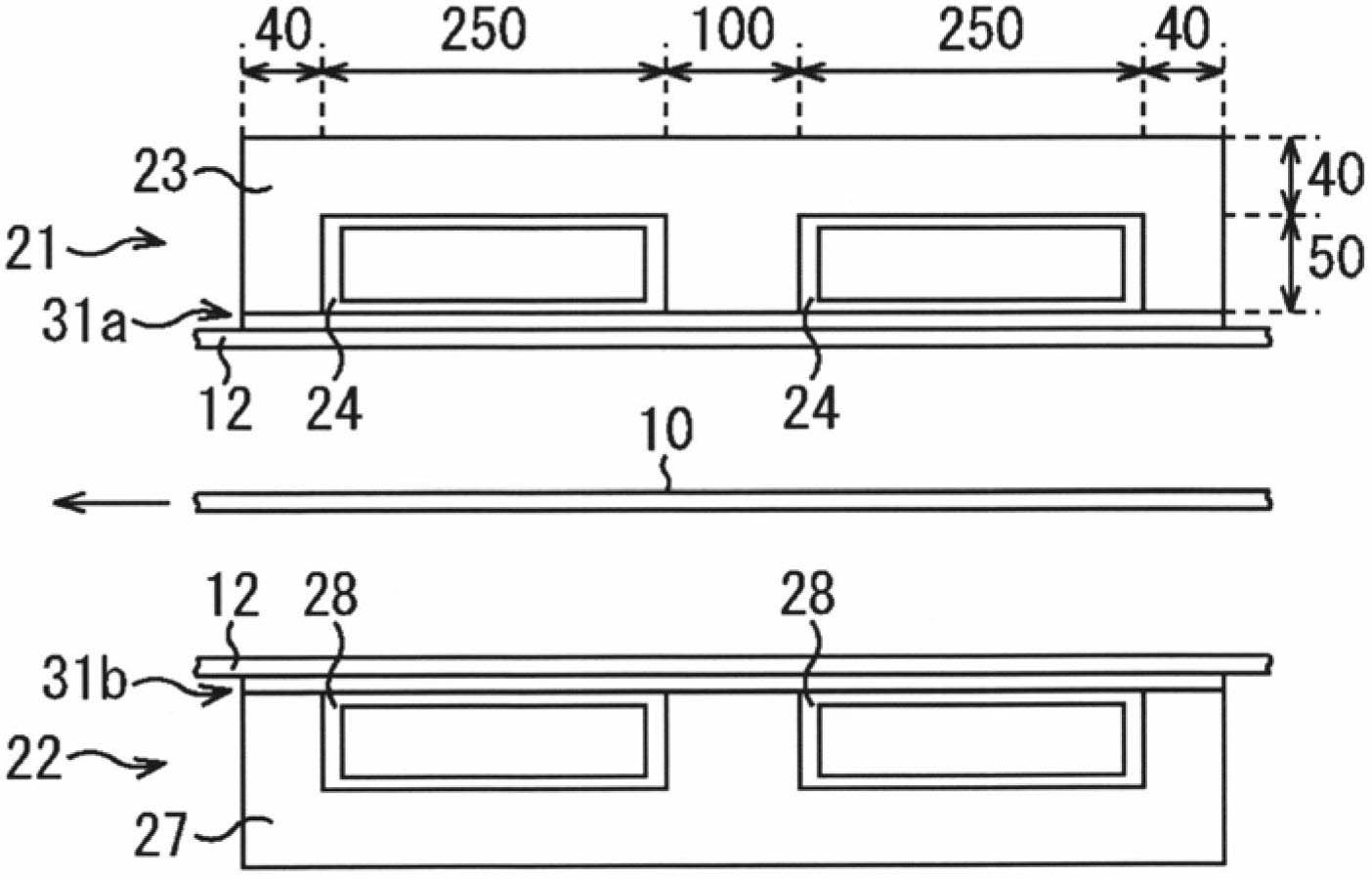

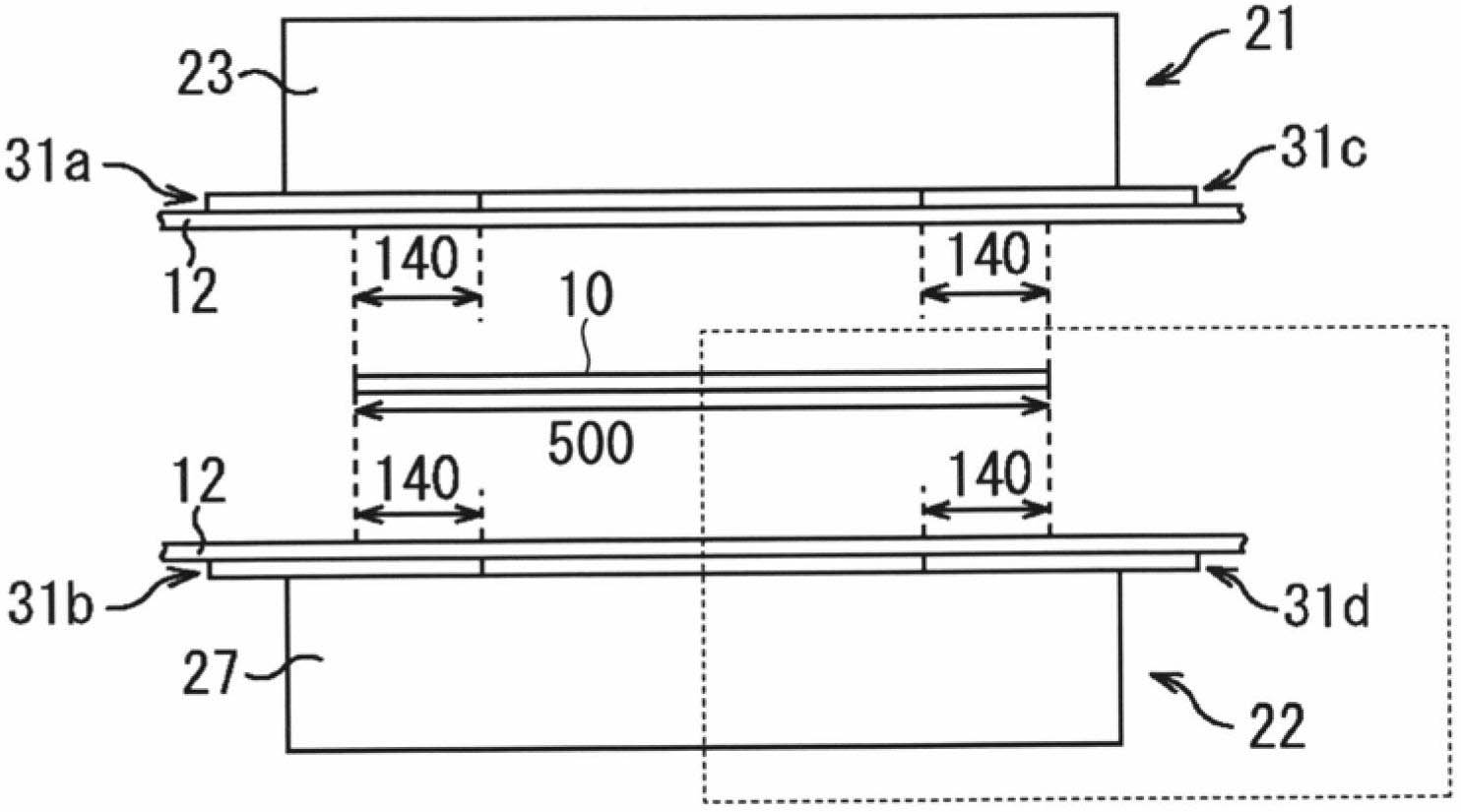

[0148] Figures 8A-8C It is a figure which shows an example of the structure of an induction heating apparatus. Figure 8A , Figure 8B , Figure 8C corresponding to Figure 2A , Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com