Tubular molded body capable of completely wrapping membrane module and industrial filter device using the tubular molded body

一种模制体、膜组件的技术,应用在工业过滤器装置,管状模制体领域,能够解决困难处理工作、溶液报废、混合比例难以控制等问题,达到节省包裹时间、减少生产成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

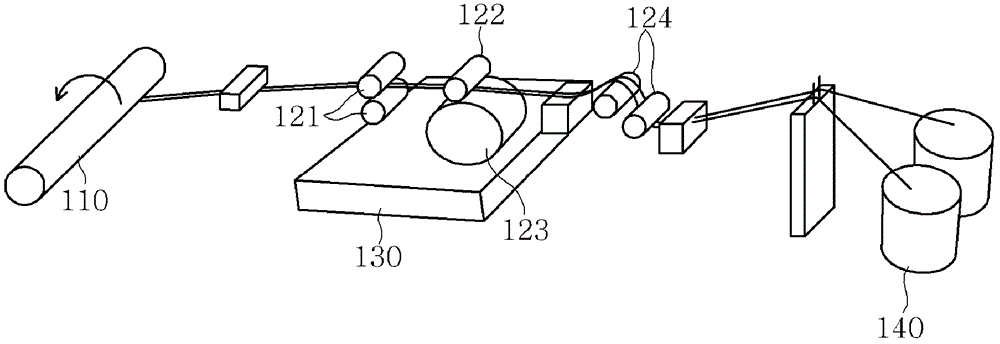

[0075] A 140 micron thick porous polysulfone support comprising a non-woven backside was immersed in an aqueous solution containing 2% by weight m-phenylenediamine (MPD) and 0.2% by weight 2-ethyl-1,3-hexanediol for 40 seconds, and removed to remove excess aqueous solution. Subsequently, the coated support was immersed in a solution containing 0.1% by weight of trimesoyl chloride (trimesoyl chloride, (TMC)) for one minute (wherein the trimesoyl chloride was dissolved in a registered trademark of (In the solvent of Exxon company), and take out and remove excess organic solution, to prepare polyamide reverse osmosis composite membrane.

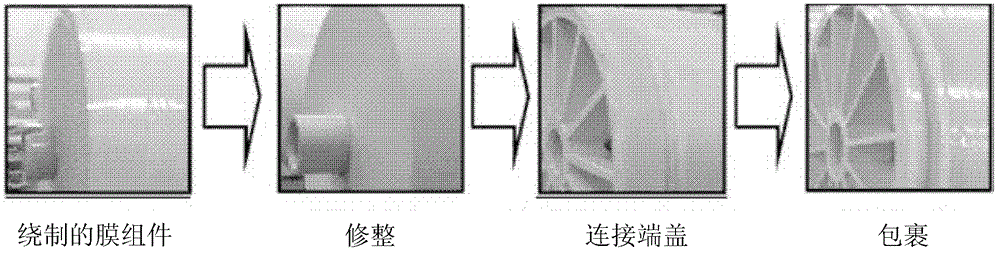

[0076] The polyamide reverse osmosis composite membrane, the warp-knitted fabric and the mesh are sequentially wound from the core to the outside to form a spiral membrane module.

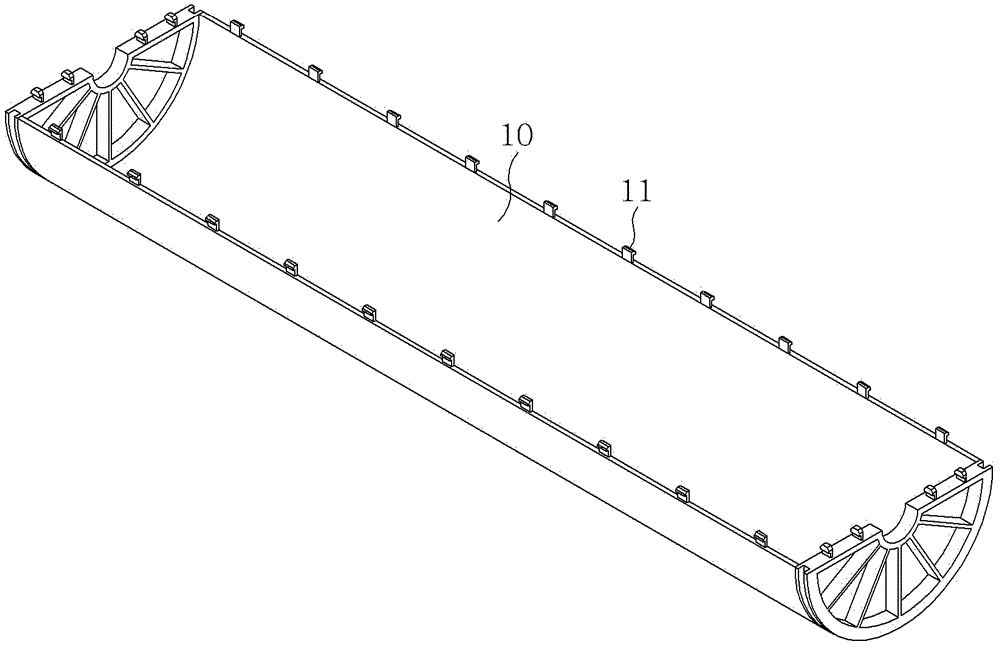

[0077] The spiral membrane module was housed in one of a pair of semi-cylindrical tubes integrally formed with end caps and made of polypropylene resin, and covere...

Embodiment 2

[0080] The implementation steps are the same as those described in Example 1, except that the spiral membrane assembly is incorporated into a pair of semi-cylindrical members 10 and 20 integrally formed with end caps and made of acrylonitrile butadiene styrene copolymer resin. the same way.

Embodiment 3

[0082] Instead of the semi-cylindrical pipe integrally formed with end caps, a cylindrical member 30 made of polypropylene resin of 1 m in length was prepared by extrusion molding. Pack the spiral membrane assembly in this cylindrical tubular molded body, and end cap 31 is threadedly installed on the two ends of cylindrical tubular molded body by threaded fastener 32 ( Figure 7 shown). Here, a spiral membrane module was prepared in the same manner as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com