Power Transmission Devices and Work Vehicles

A technology for power transmission devices and vehicles, which is applied to power devices, transmission parts, lifting devices, etc., can solve problems such as large accommodation space, and achieve the effect of reducing space and reducing the space in the axial direction of the wheel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, an example of an embodiment of the present invention will be described in detail with reference to the drawings.

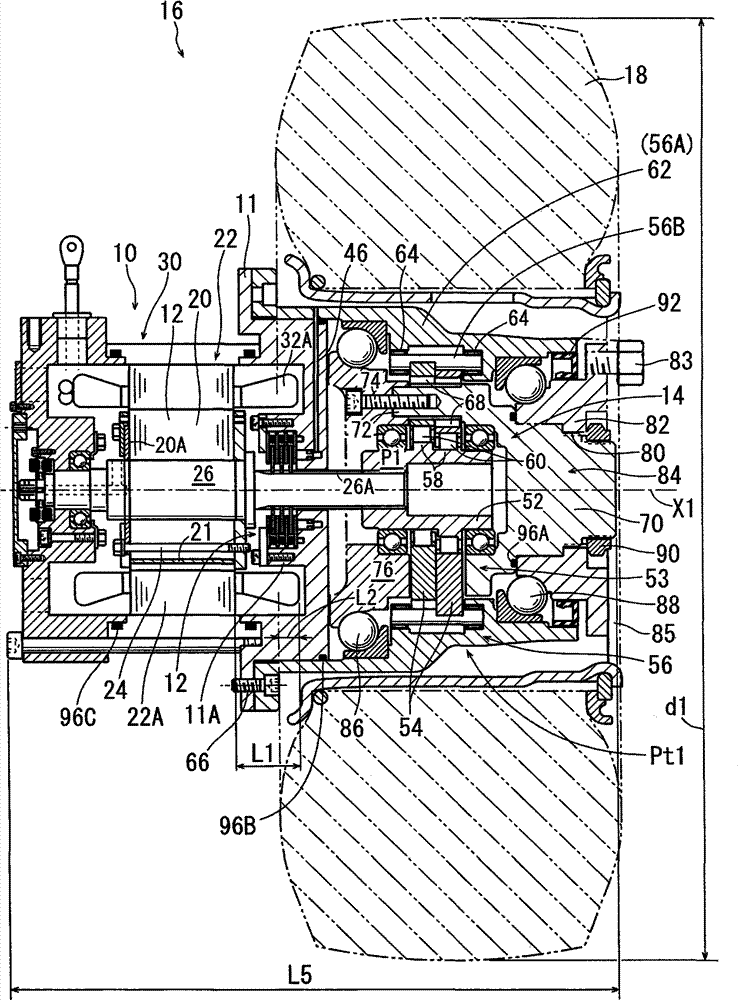

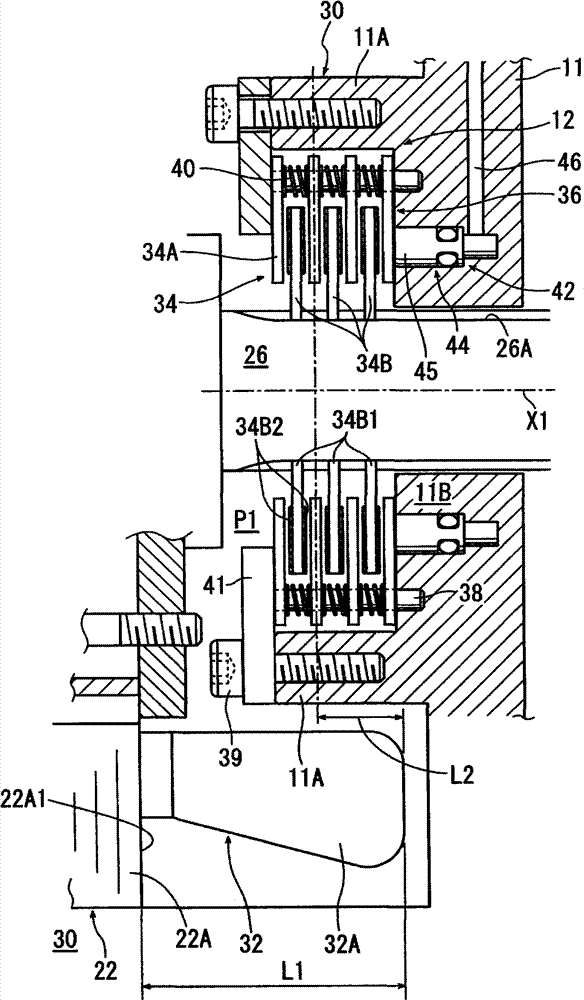

[0022] figure 1 It is a cross-sectional view showing a structure in which a power transmission device according to an example of an embodiment of the present invention is applied to drive a wheel of a forklift, figure 2 It is an enlarged cross-sectional view of the main part near the braking mechanism.

[0023] This power transmission device Pt1 is equipped with an IPM motor 10, a brake mechanism 12, and a speed reducer 14, and is used to independently drive each front wheel (wheel: figure 1 Only one side is shown) 18.

[0024] The IPM motor 10 has a rotor 20 and a stator 22 for extracting a rotational output. A plurality of plates (plates) 20A are stacked on the rotor 20 , and permanent magnets 21 are embedded in the rotor 20 . The IPM motor 10 with permanent magnets 21 embedded in the rotor 20 is more efficient than an SPM motor (a motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com