Method for testing capacitive touch screens and testing equipment thereof

A technology of capacitive touch screen and testing method, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve problems affecting production progress, not suitable for mass production, and slow testing speed, and achieve the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

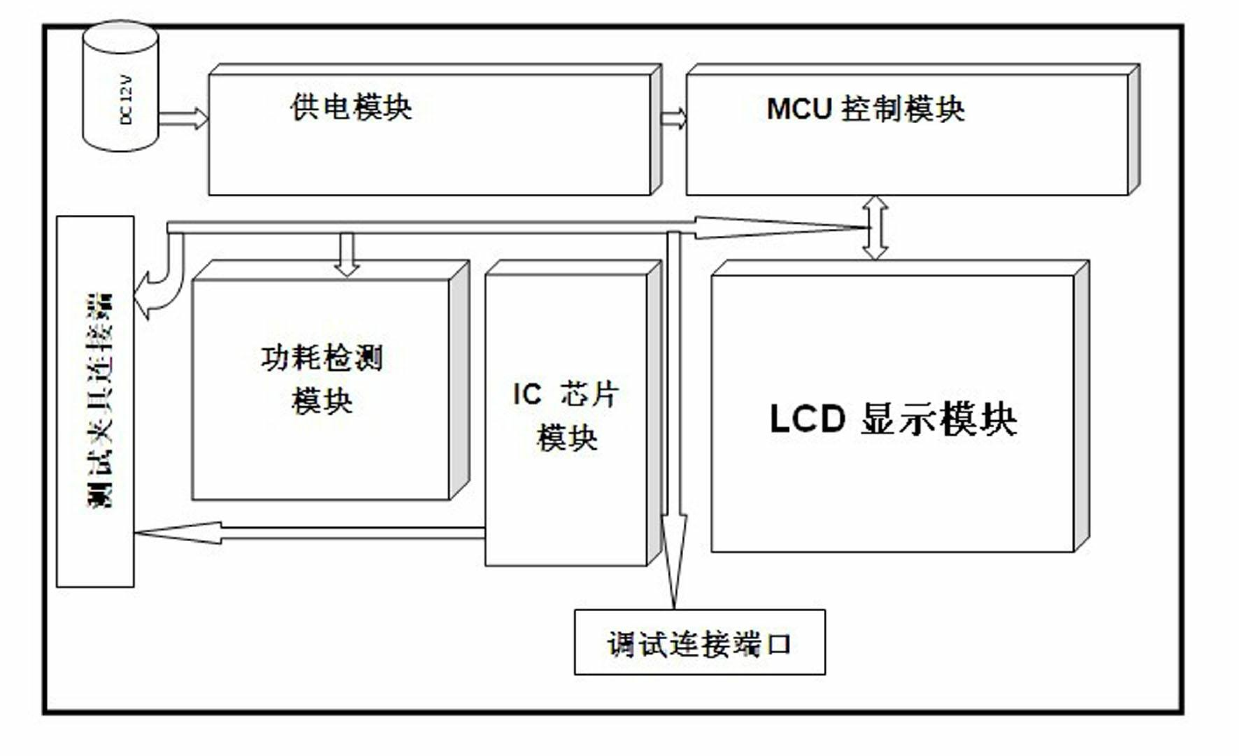

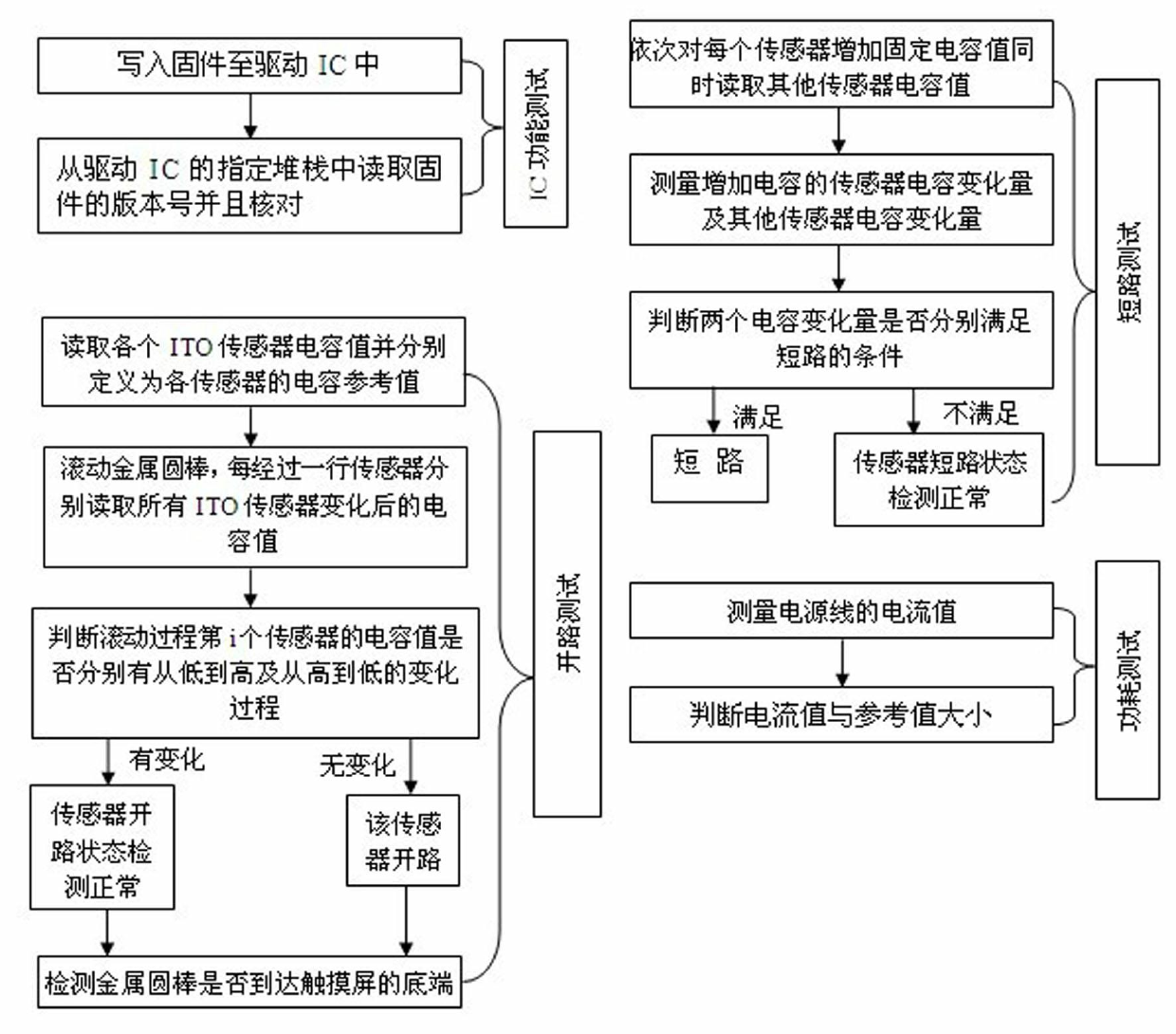

[0027] A test method for a capacitive touch screen according to the present invention includes IC function test, power consumption test, short circuit test and open circuit test.

[0028] The IC function test includes the following steps: writing firmware into the driver IC, reading and checking the version number of the firmware from the designated stack of the driver IC.

[0029] Described open circuit test comprises the steps:

[0030] a1. Read the capacitance value of each ITO sensor on the touch screen through the drive IC, and define the capacitance value read by each ITO sensor as the capacitance reference value of the corresponding ITO sensor;

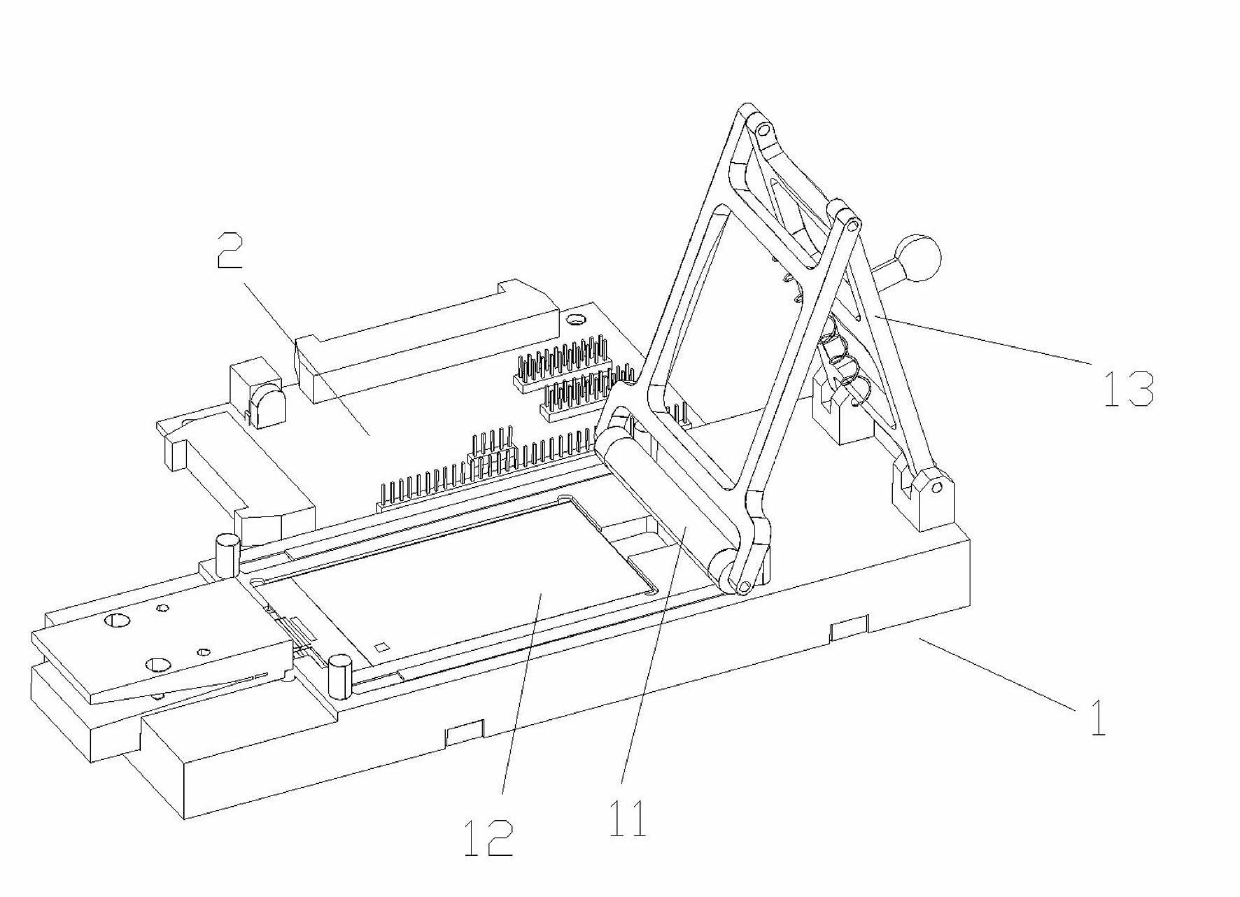

[0031] a2. Set a metal round bar that is close to and transversely across the surface of the touch screen, and the metal round bar is parallel to the row direction of the touch screen;

[0032] a3. Roll the metal round bar from the top to the bottom of the touch screen, and each time the metal round bar passes through a row of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com