Manual splitter

A splitting machine and manual drive technology, applied in the field of obstacle breaking rescue, can solve the problems of large and cumbersome mechanical systems, cannot be carried by one person, personal injury, etc., and achieve the effects of simple and compact structure, broad application prospects, and weight reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

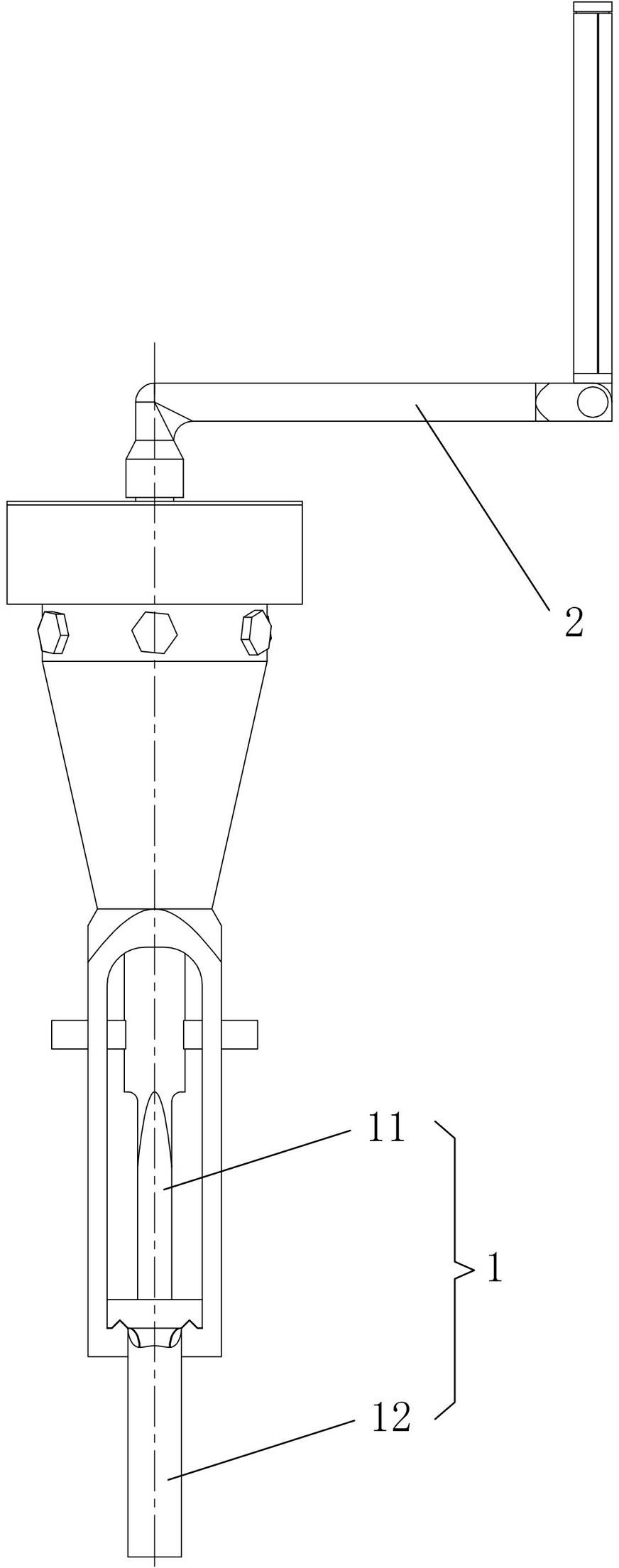

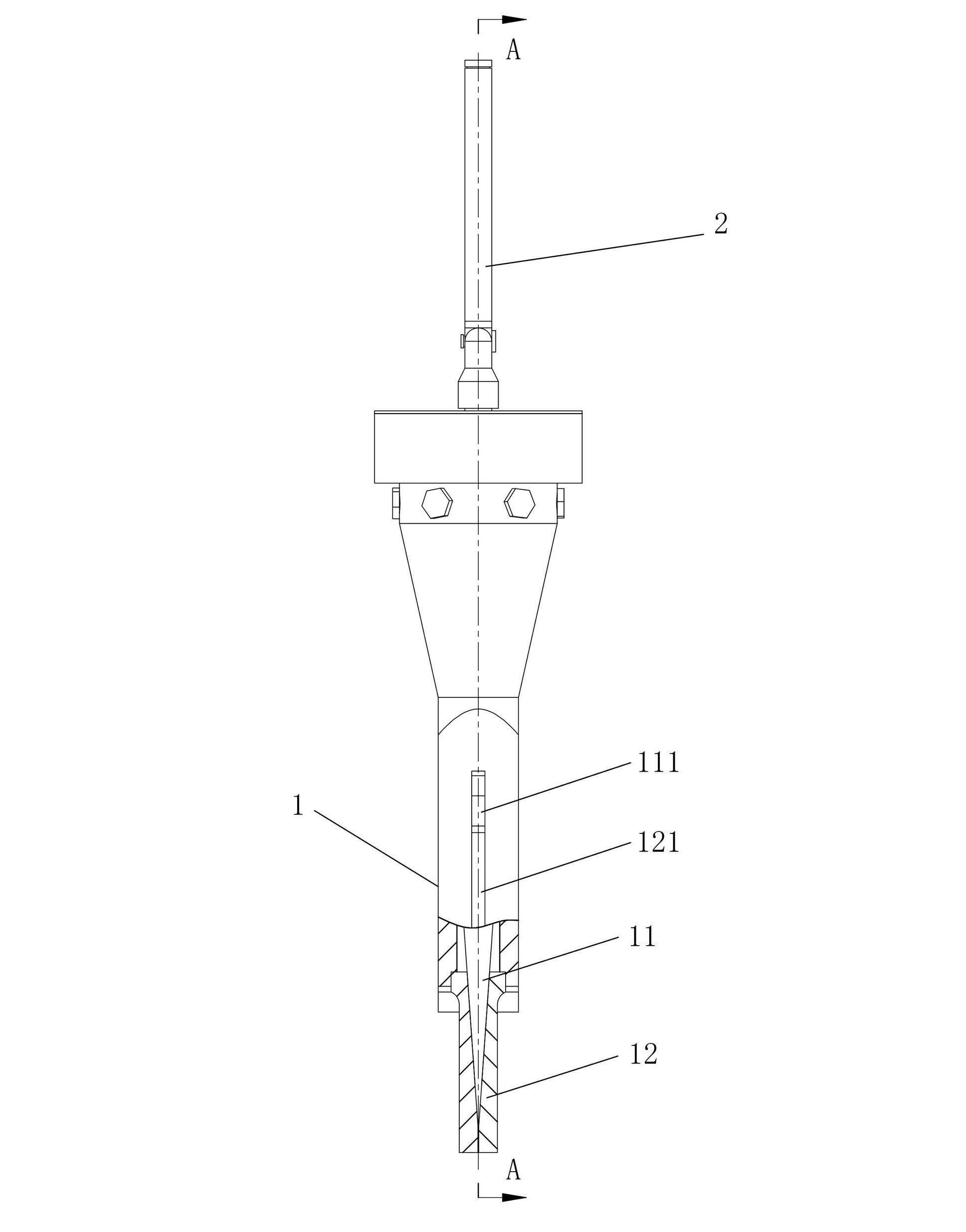

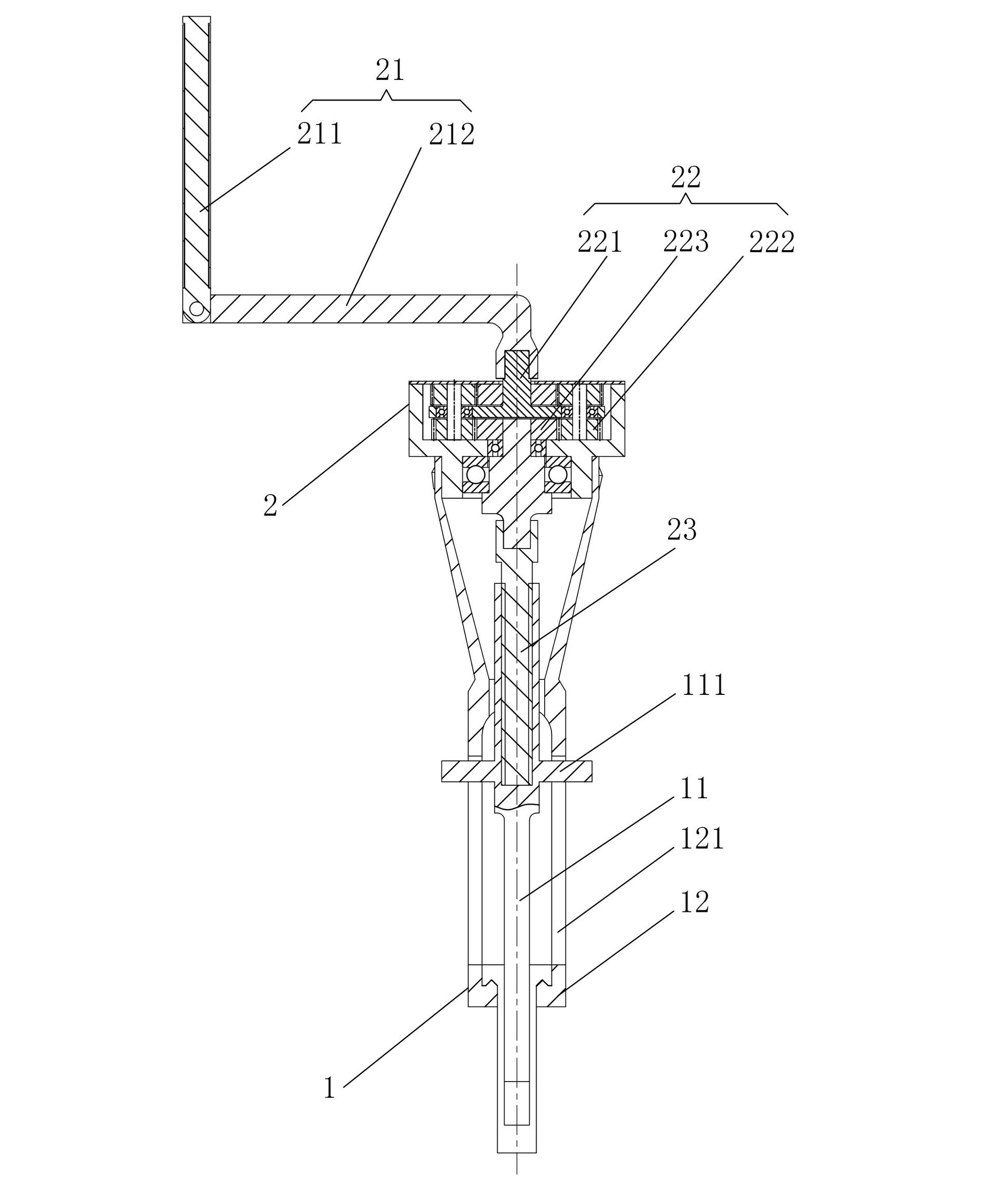

[0019] Figure 1 to Figure 3 A kind of manual splitting machine embodiment of the present invention is shown, and this manual splitting machine comprises splitting mechanism 1, and splitting mechanism 1 is connected with the manual driving mechanism 2 that is used to drive splitting mechanism 1 to work, and its structure is simple and compact, The weight is greatly reduced, which avoids the bulky disadvantage of the splitter that uses power or fuel as the power source, and is easy to carry by a single person, especially suitable for special occasions such as post-disaster emergency rescue and breaking obstacles.

[0020] In this embodiment, the manual drive mechanism 2 includes a drive handle 21, a planetary gear booster transmission assembly 22 and a screw shaft 23, the drive handle 21 is connected to the input end of the planetary gear booster drive assembly 22, and the planetary gear booster drive assembly 22 The output end is connected with the screw shaft 23, and the scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com