Brick pile reshaping mechanical device

A technology of mechanical device and brick pile, which is applied in the field of mechanical device for automatic shaping of brick pile, can solve the problems of uneven brick body, high labor intensity, poor labor conditions, etc., so as to eliminate gaps, improve work efficiency, and improve operation handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

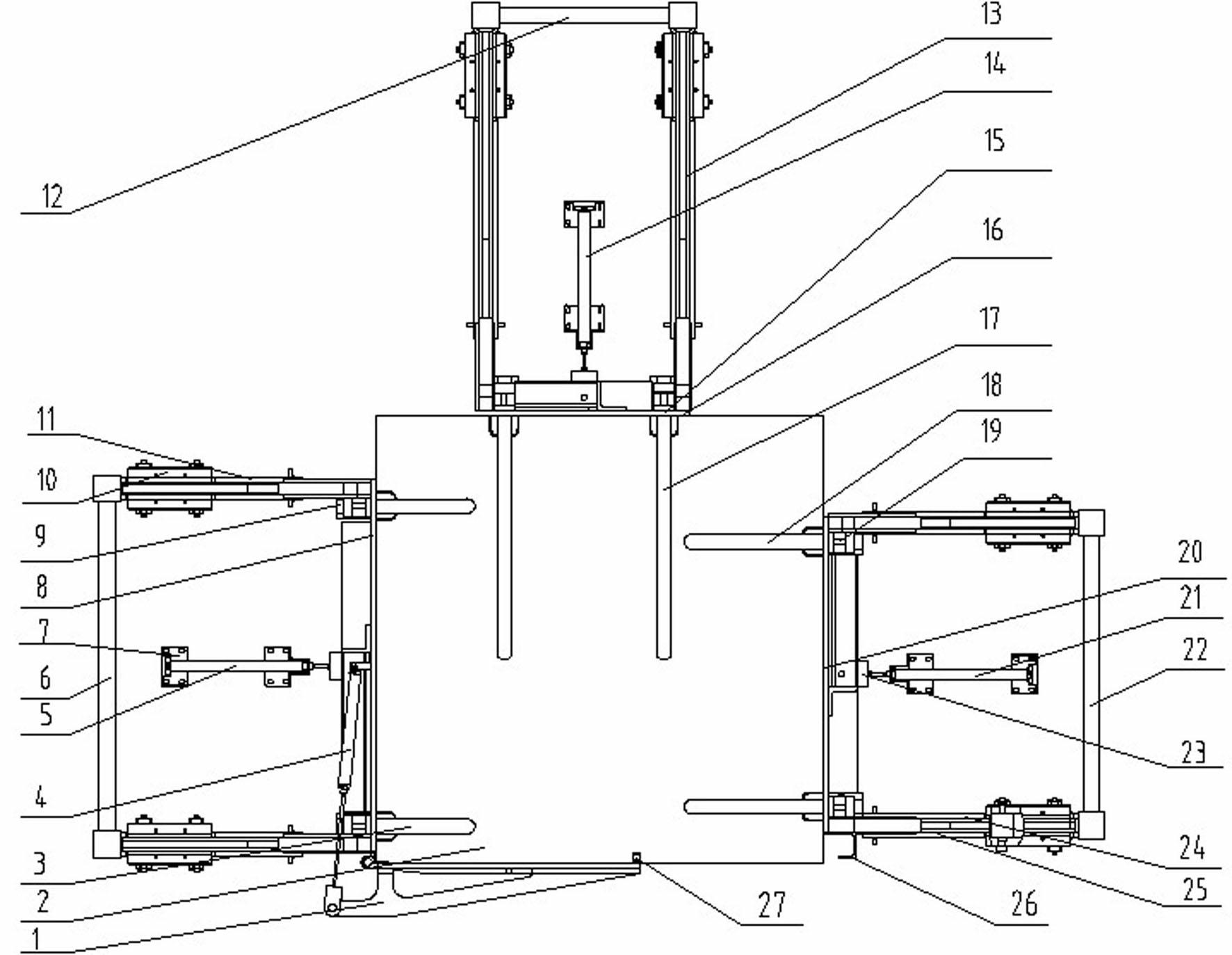

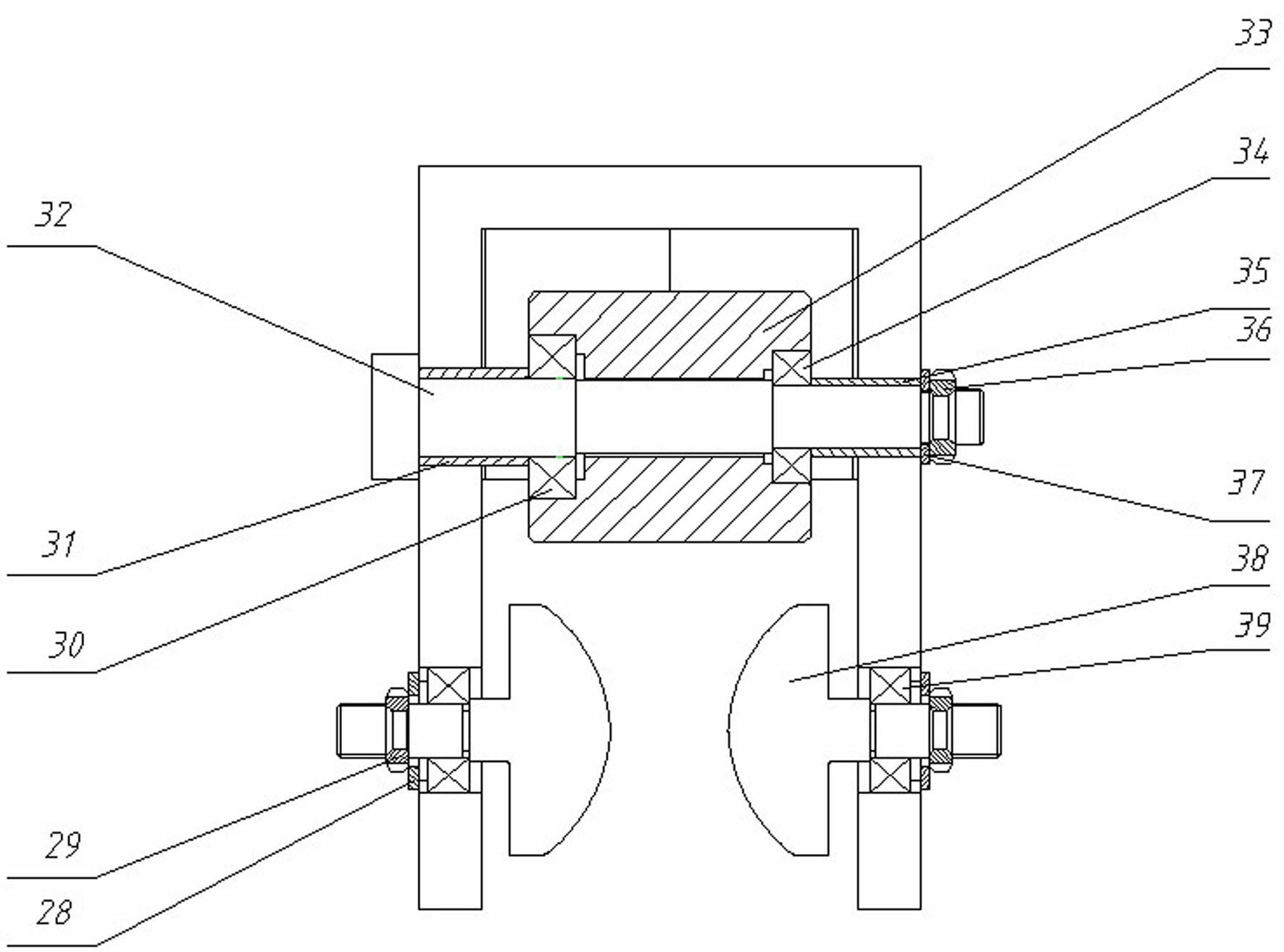

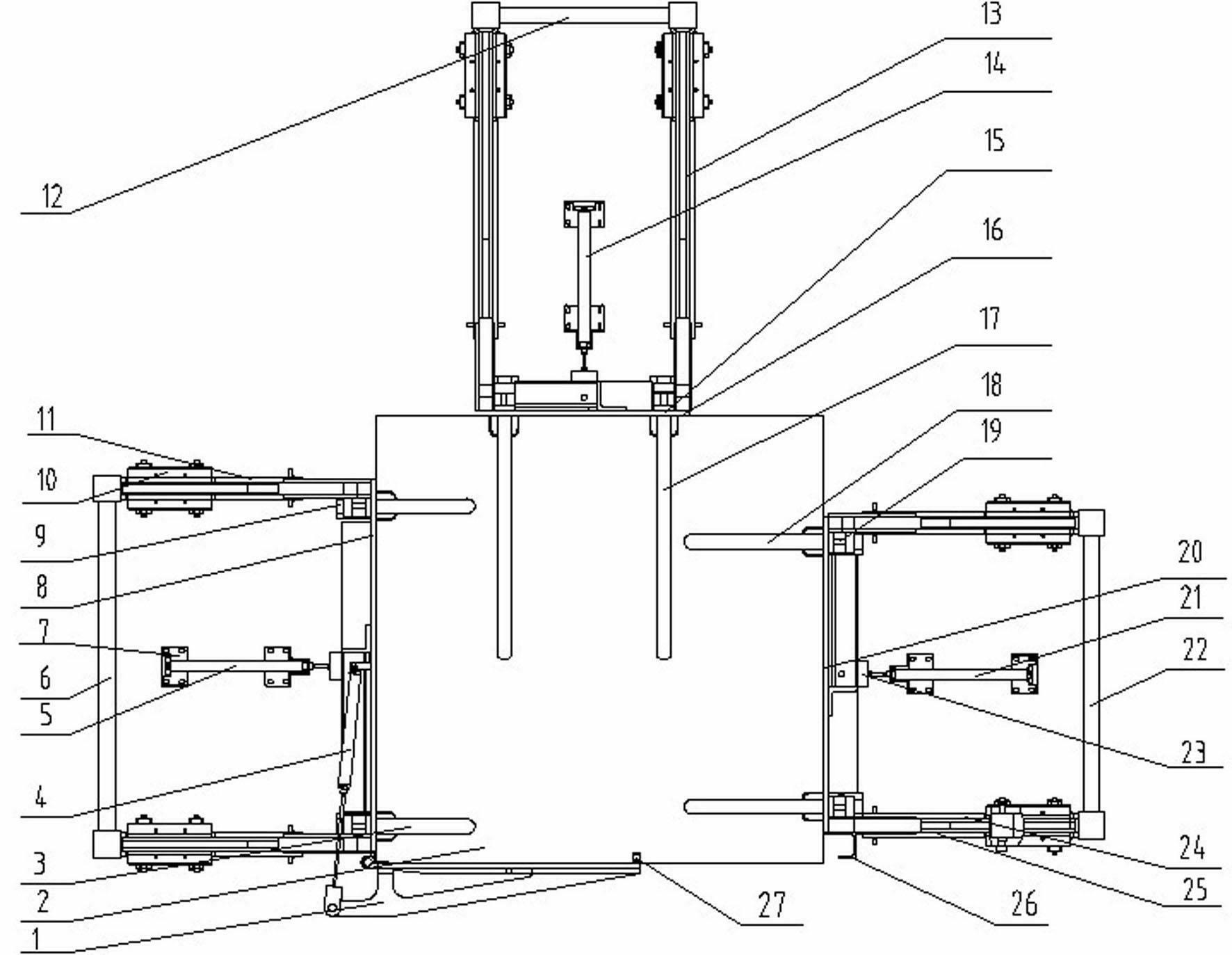

[0020] The brick heap shaping mechanical device provided by the present invention is mainly composed of a dodge door, a base plate, six guide frames, three push plates, an I-shaped steel track and four air cylinders, wherein: one end of the dodge door is connected to the first air cylinder The piston end and one end of the first push plate are connected by a hinge, and the cylinder end of the first pneumatic cylinder and the other end of the first push plate are connected by a hinge. In the initial state, the movable door forms an angle of 90 degrees with the first push plate The second, third and fourth pneumatic cylinders, the pistons at one end are fixedly connected with the connecting blocks of the first, second and third push plates through threaded connections respectively, and the cylinder body at the other end is respectively connected with the corresponding cylinder block by bolts The bottom of the cylinder seat is fixed on the ground with anchor bolts; the first, seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com