Special material for polyvinyl chloride (PVC) protection railing of highway and production method thereof

A technology for highways and polyvinyl chloride, applied to materials for highways and its production, PVC modified special materials for highway protection barriers and its production fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

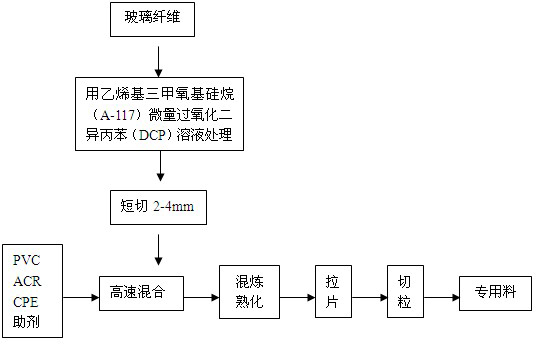

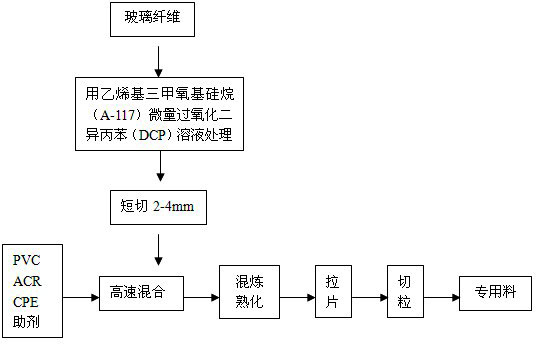

Method used

Image

Examples

Embodiment 1

[0046] A special material for expressway protective barriers and its preparation method, which uses glass fiber and matrix resin polyvinyl chloride (PVC) to compound, and treats the surface of the glass fiber with a coupling agent and the matrix resin polyvinyl chloride (PVC) through a modifier. PVC) after modification, grafting and cross-linking the olefinic bond of the coupling agent connected to the glass fiber with the matrix resin polyvinyl chloride (PVC), kneading to form a composite material, and then granulating according to the conventional method to obtain A special material for highway protection barriers. Among them, the formula (by weight and mass parts) of the special material for the highway protective barrier includes at least the following materials:

[0047] Base resin polyvinyl chloride (PVC) 100 parts;

[0048] Acrylate series modifier (ACR) 8-10 parts;

[0049] Chlorinated polyethylene modifier (CPE) 8-12 parts;

[0050] 15-25 parts of glass fiber;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| aging coefficient | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com