Cooling water circulating and recycling system for normalizing furnace

A technology of cooling water circulation and normalizing furnaces, which is applied to furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of high operating costs, large amounts of cooling water, large particle size of sewage impurities, etc., to achieve simple installation and operation, prolong equipment life, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

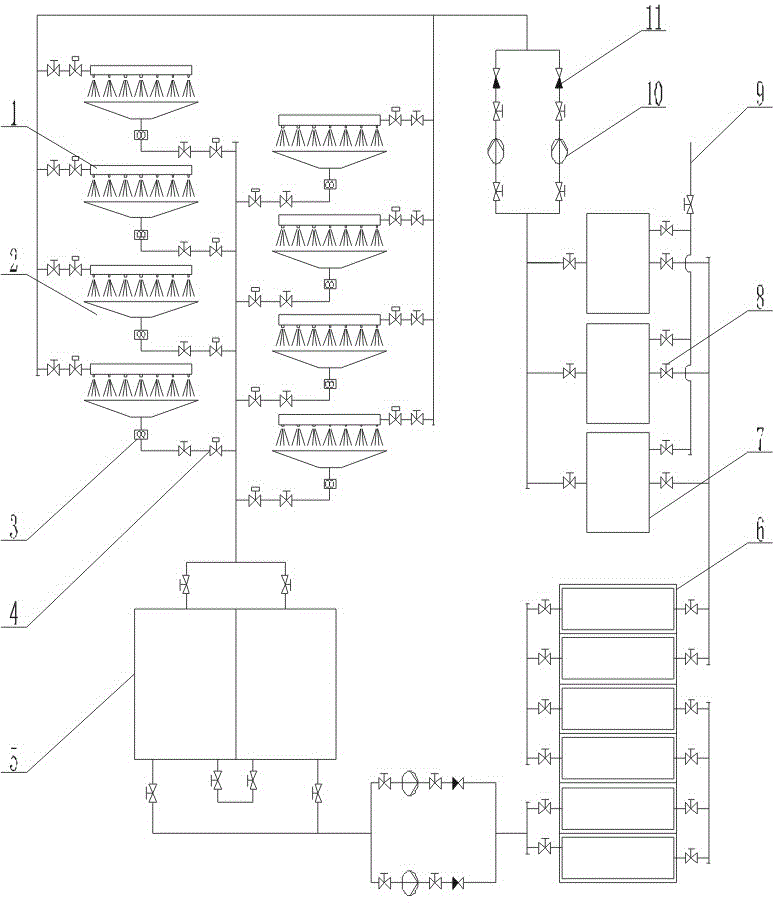

[0031] Such as figure 1 As shown, it includes an aerosol or water spray device 1, a crushing device 3, a sedimentation tank 5, a coarse filter 6, and a fine filter 7; the aerosol or water spray device 1 sprays and cools a steel plate or a steel strip, A large number of iron oxides of different sizes are produced during the process, and the cooling water containing iron sheets enters the sump 2; the crushing device 3 is installed at the lower part of the sump 2, and is connected with a sedimentation tank, a coarse filter, and a fine filter in sequence.

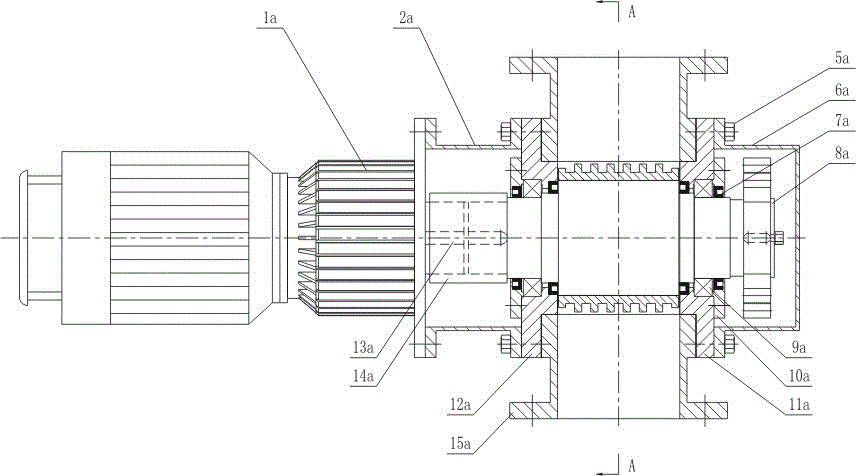

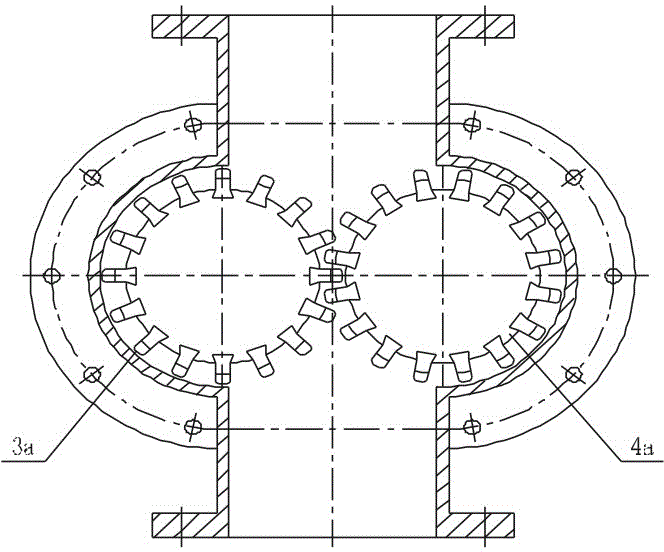

[0032] Such as figure 2 , image 3 , Figure 4 As shown, the crushing device includes a housing 15a, a motor 1a, a pinion shaft 3a, and a large gear shaft 4a. There is a sewage inlet at the top of the housing, and a sewage outlet at the bottom of the housing; the motor 1a is connected with the speed reducer 2a, The outp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com