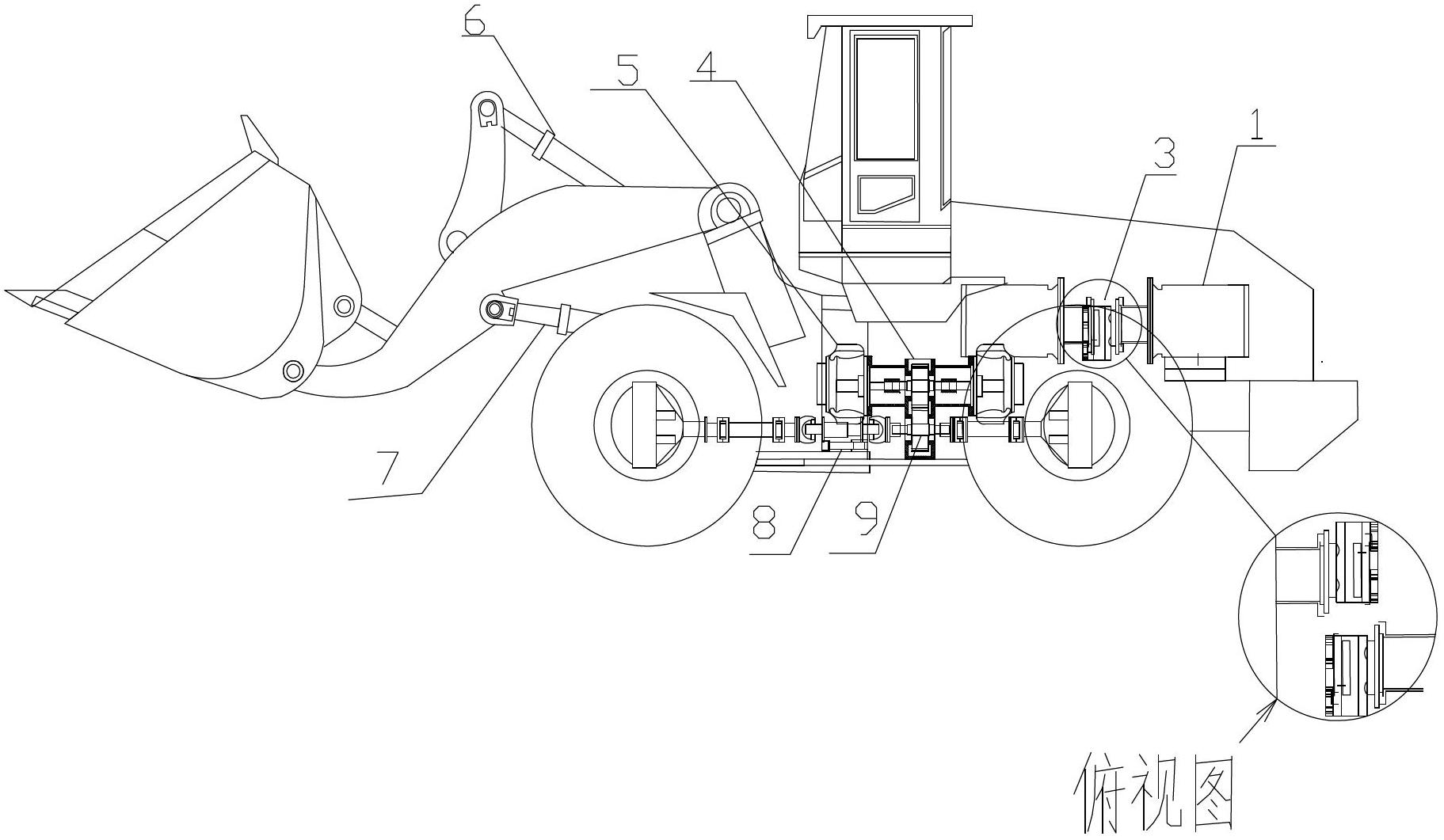

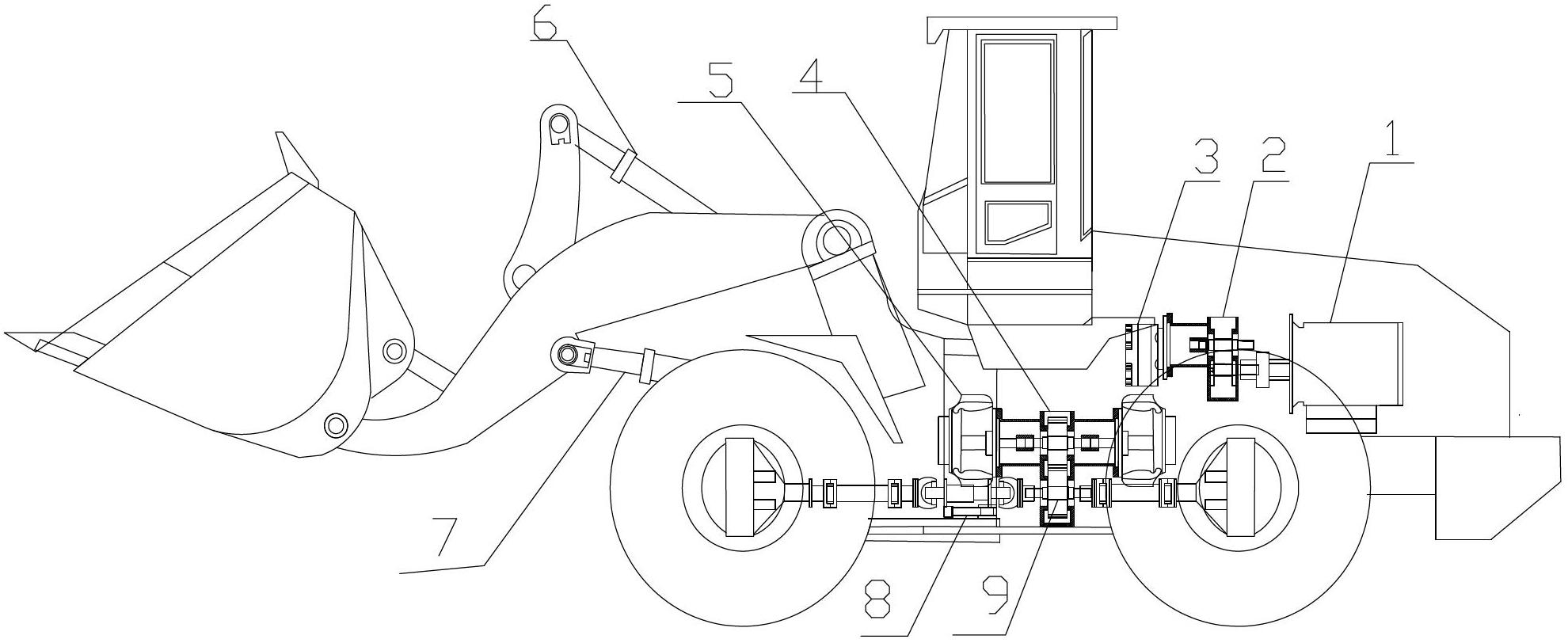

Pure-hydraulic electric loader

A loader and electric technology, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the problems of insufficient hydraulic transmission and achieve simple structure and low maintenance costs , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

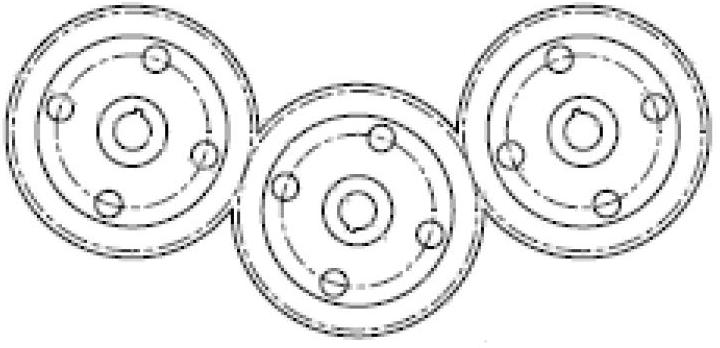

[0025] The pure hydraulic electric loader provided by the embodiment of the present invention adopts a brand-new technical solution without using a traditional hydraulic torque converter, which greatly improves the transmission efficiency, and the motor can realize forward and reverse rotation; pure hydraulic pilot control, simple structure and easy operation Convenience and reliable performance. The cost of mechanical manufacturing is much lower than that of traditional loader (forklift) hydraulic mechanical transmission. The motor is used as power instead of the internal combustion engine. The manufacturing precision of the internal combustion engine is higher than that of the motor and the manufacturing system. The motor is a product with no or few faults, and the workload of its use and maintenance is less. Compared with the internal combustion engine, the maintenance cost can be greatly reduced. The total cost of the present invention is not higher than that of a loader (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com