Ha-NTP functional fireproof insulation board for outer wall and inner wall and manufacture method of Ha-NTP functional fireproof insulation board

A fire-proof thermal insulation board and thermal insulation board technology, which is applied in the directions of thermal insulation, fire prevention, climate change adaptation, etc., can solve the problems of environmental air pollution, affecting physical health, etc., and achieve the effects of high labor intensity, improvement of intellectual development level, and happy spirit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

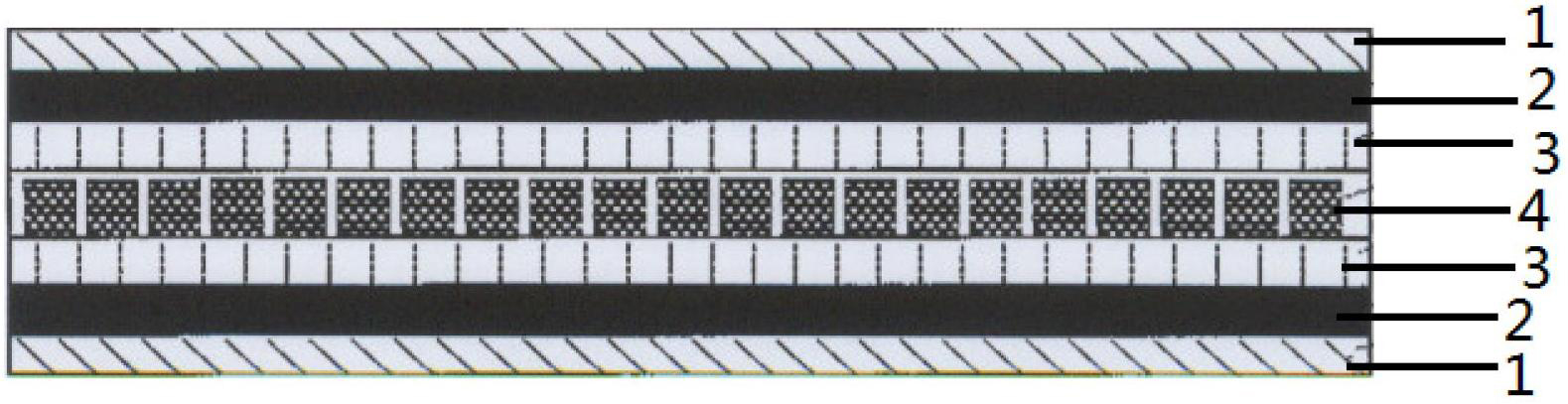

[0035] Such as figure 1 As shown, the Ha-NTP functional outer wall and inner wall fire-proof and thermal insulation board provided by the present invention includes a thermal insulation layer, a flame-retardant decorative layer arranged on both sides of the thermal insulation layer, and an anion is arranged between the thermal insulation layer and the flame-retardant decorative layer. The release layer, the two sides of the anion release layer are respectively compounded with the thermal insulation layer and the flame retardant decoration layer. The thermal insulation layer includes a main thermal insulation layer and a reinforced thermal insulation layer, and the reinforced thermal insulation layer is arranged on both sides of the main thermal insulation layer; the main thermal insulation layer is made of composite inorganic materials; and the reinforced thermal insulation layer is made of fire rock wool.

[0036] The composite inorganic material is formed by mixing two or mo...

Embodiment 2

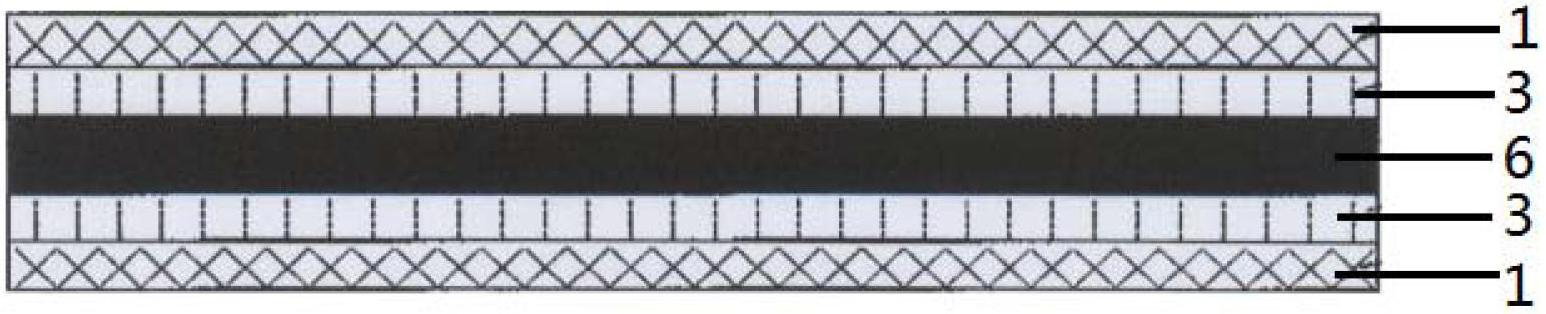

[0047] see figure 2As shown, the difference with Embodiment 1 is that it is provided with five layers, which are respectively from outside to inside: a flame-retardant decorative layer, a reinforced thermal insulation layer, an anion releasing thermal insulation layer for the main body, a reinforced thermal insulation layer and a flame-retardant decorative layer. Add a catalyst to the negative ion powder, mix it with the main insulation layer in proportion to make the main negative ion release insulation layer, heat and dry it with steam, then put it into a vacuum bag decorated with aluminum foil glass fiber cloth and vacuumize it to make the insulation layer plate.

[0048] Send the prepared thermal insulation board to Beijing Quality Inspection and Testing Center for inspection. The size of the thermal insulation board submitted for inspection is 300x300x7.9mm, and four layers of reinforced insulation layers are arranged on both sides of the main insulation layer, and each ...

Embodiment 3

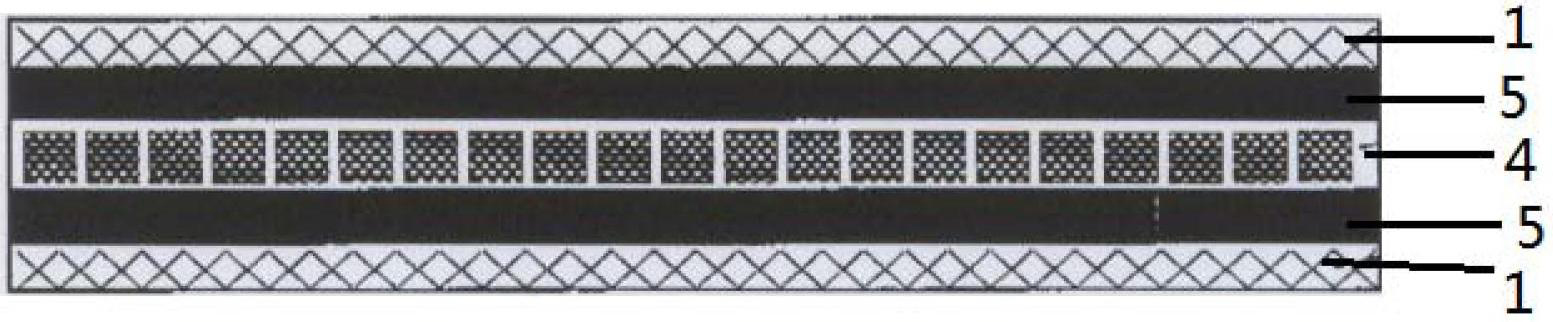

[0050] see image 3 , Also set up five layers, from outside to inside are: flame retardant decorative layer, strengthened anion release insulation layer, main body insulation layer, strengthened anion release insulation layer and flame retardant decoration layer.

[0051] The negative ion powder is added with a catalyst and mixed with fire rock wool in proportion, and then crushed, beaten, dehydrated, and steamed (180°C) to form a reinforced negative ion release insulation layer. Lay the enhanced negative ion release insulation layer and the main insulation layer in sequence, and put them into a vacuum bag decorated with aluminum foil glass fiber cloth, and vacuumize to make the insulation board.

[0052] The serial numbers of the above embodiments of the present invention are for description only, and do not represent the advantages and disadvantages of the embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com