Artificial stone plane material with strengthening framework and method for preparing same

A skeleton and stone surface technology, which is applied in the field of artificial stone surface material with reinforced skeleton and its preparation, can solve the problems of delamination between plate and inner lining or composite plate, increase of artificial stone use cost, and low service life. Achieve the effects of not easy to delaminate and crack, light weight and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Prepare 2cm artificial stone surface material

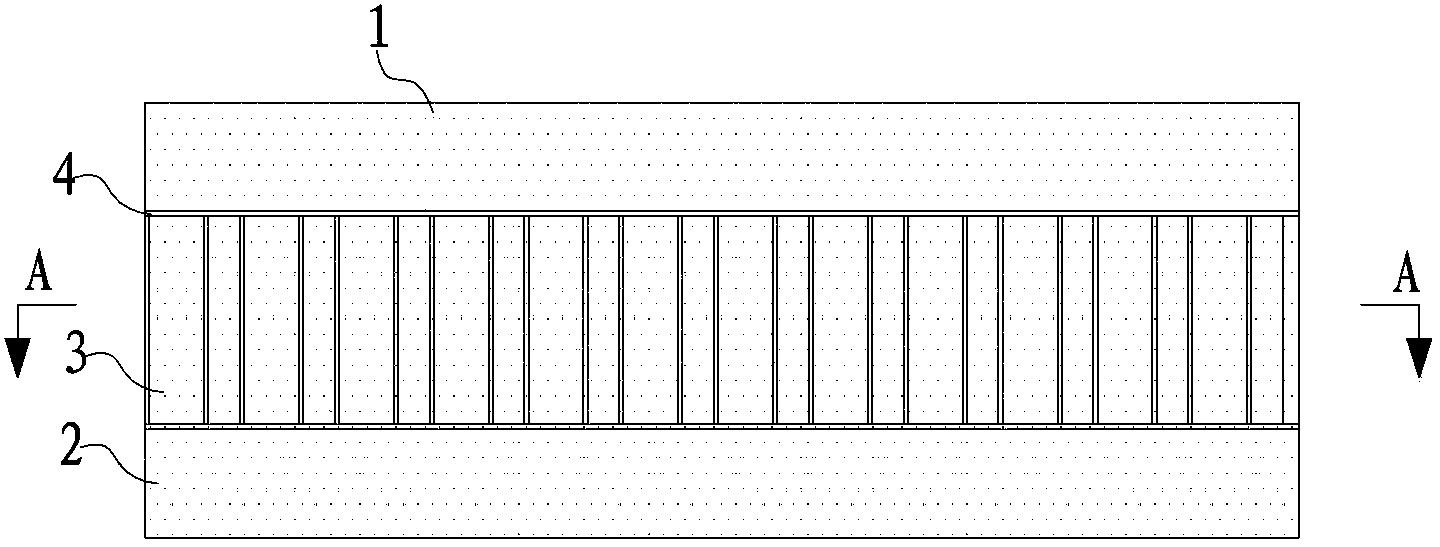

[0038] Such as figure 1 with figure 2 As shown, an artificial stone surface material with a reinforced skeleton includes a surface material body, a reinforced skeleton is pre-embedded in the surface material body, and a gap connecting up and down is provided on the reinforced skeleton.

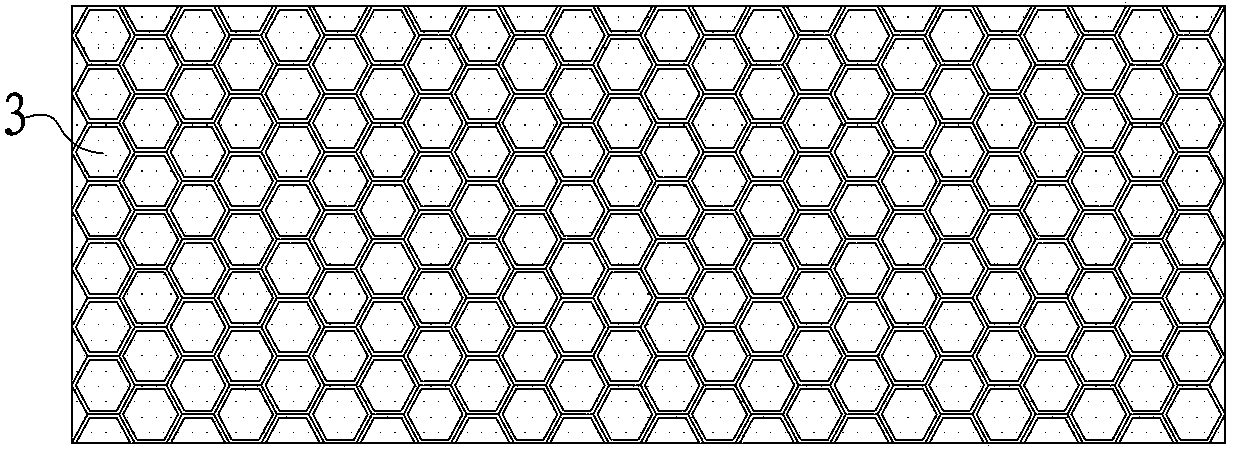

[0039] The reinforced frame includes two layers of glass fiber nets 4 and a honeycomb interlayer 3 between the two glass fiber nets 4; the thickness of the materials on both sides of the reinforced frame is 5mm, and the actual thickness can be determined according to the amount of the actual material. Adjustment, generally 5-6mm. The thickness of the reinforced frame is 10mm, and it can also be adjusted according to actual needs, generally 8-10mm.

[0040] The through holes of the honeycomb interlayer are regular hexagonal through holes and are made of plastic material.

[0041] The mesh shape of the glass fiber mesh is a rectangle, t...

Embodiment 2

[0045] Preparation of artificial stone surface material with a thickness of 3cm

[0046] The structure is the same as that of the artificial stone surface material in Example 1, except that the thickness of the materials on both sides of the reinforcing frame is 6 mm, which can be adjusted according to actual needs, generally 5-6 mm. The thickness of the reinforced frame is 18mm, and the thickness of the support layer can also be adjusted according to actual needs, generally 12-20mm.

[0047] The preparation method of the artificial stone surface material in this embodiment is the same as that in Embodiment 1.

Embodiment 3

[0049] Preparation of artificial stone surface material with a thickness of 2cm

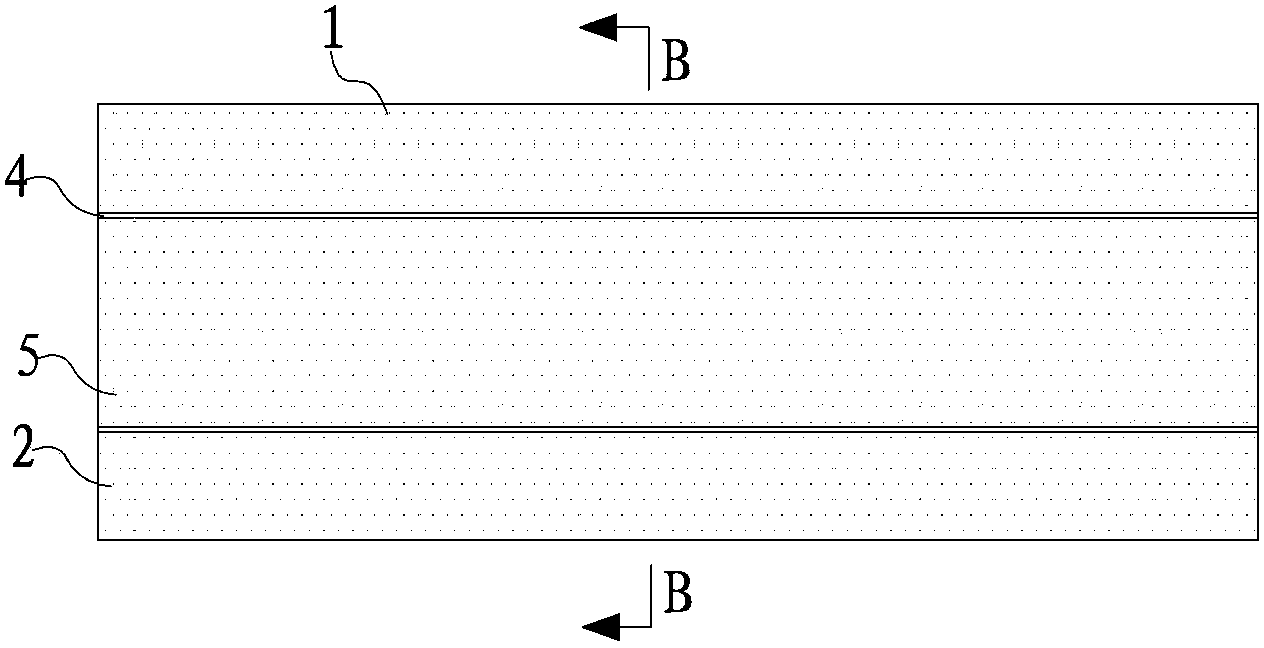

[0050] Such as image 3 with Figure 4 As shown, the structure is the same as that of the artificial stone surface material in Example 1, except that the reinforcing skeleton includes two layers of glass fiber nets 4 and hollow plastic tubes 5 arranged in parallel between the two glass fiber nets. In addition, the reinforced skeleton is prefabricated to form a whole, and then the whole is laid on the partially cured lower material. The specific method is:

[0051] (i) Lay the hollow plastic tubes 5 closed at both ends in parallel on the first layer of glass fiber mesh, leaving a gap 6 between two adjacent hollow plastic tubes, and then lay the second layer of glass fiber mesh on the top of the hollow plastic tubes Finally, the first layer of glass fiber mesh, the hollow plastic pipe 5 and the second layer of glass fiber mesh are connected to each other to form a whole by using connectors. In th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com