Coaxial and automatic water feeder for water drill

A technology of automatic water supply and water feeder, which is applied in the direction of liquid/gas jet drilling, etc., can solve the problems of increased cost, slow promotion, troublesome maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

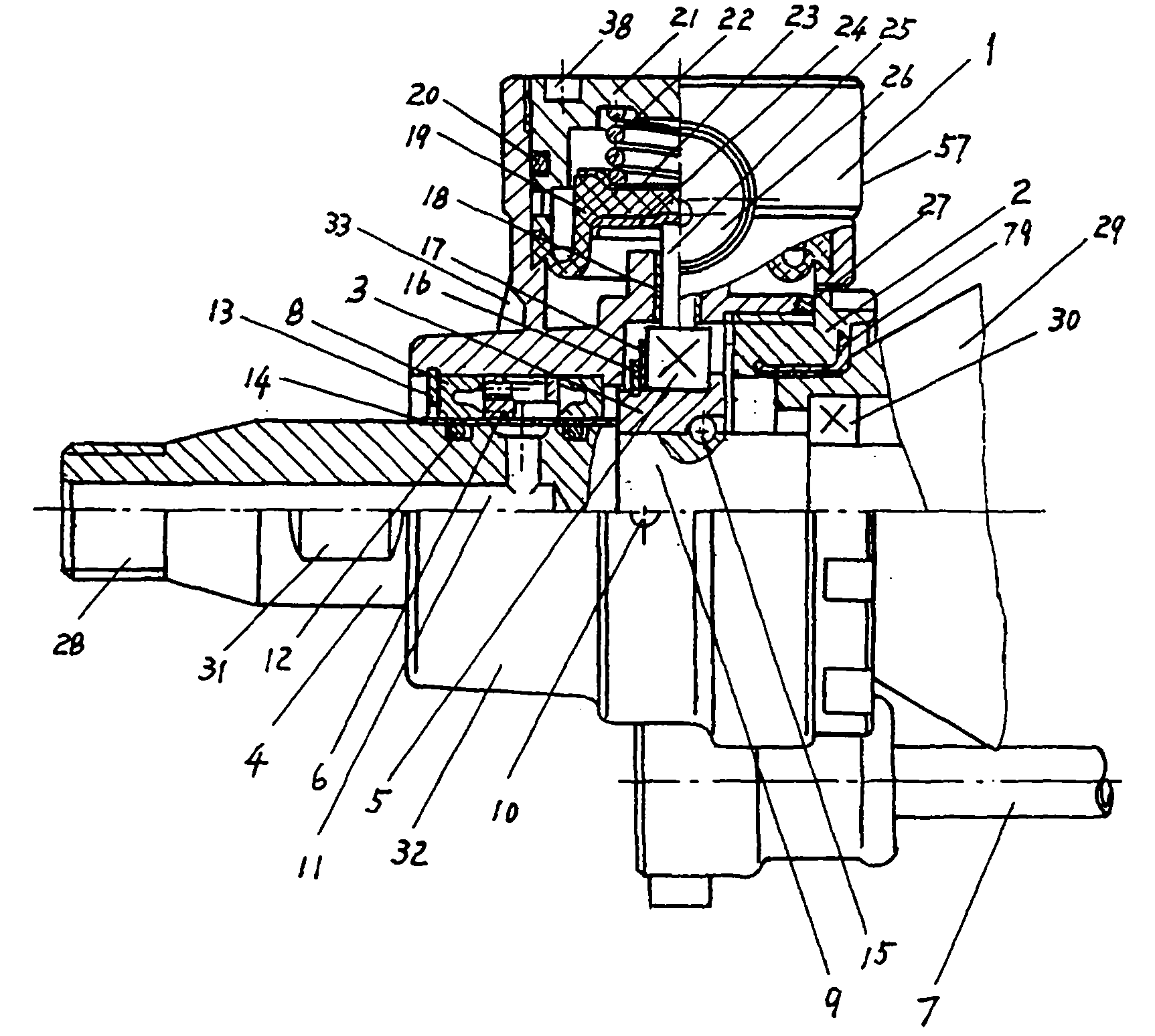

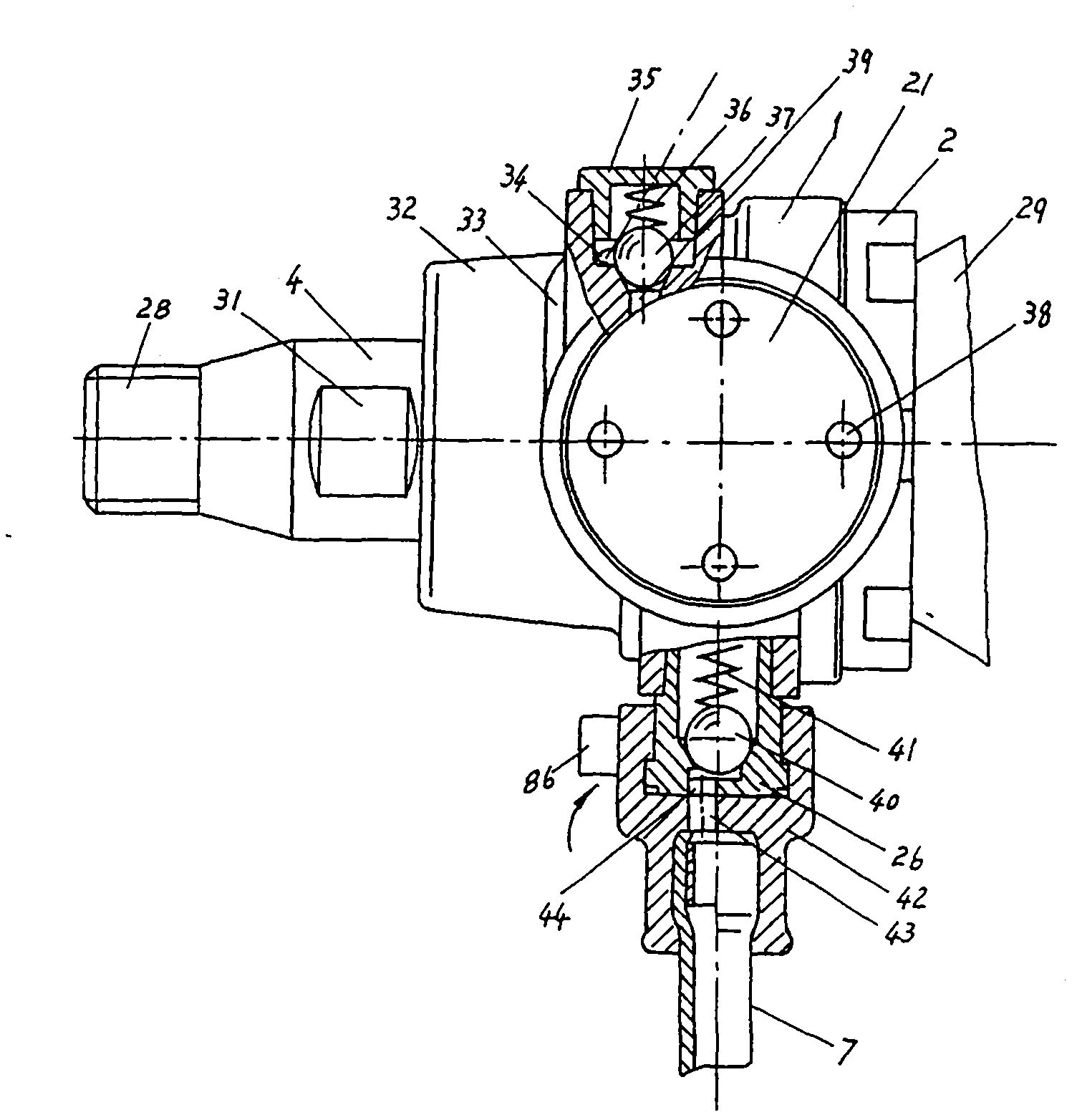

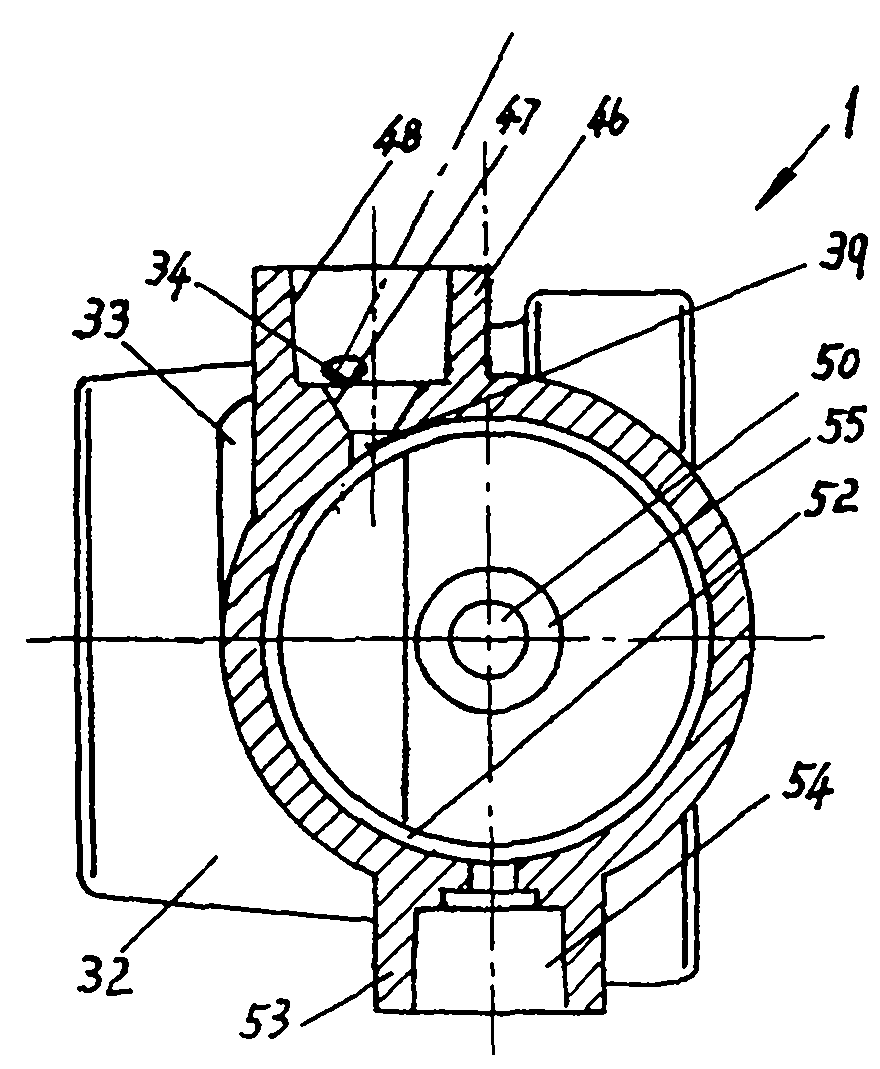

[0019] Such as figure 1 The schematic diagram of the overall structure of the coaxial automatic water feeder for the rhinestone is shown. This figure expresses the coaxial automatic water feeder for the rhinestone. The disassembled accessory type water supply device is mounted on the threaded thread at the front end of the water drill reduction box 29 with reverse buckle transition threaded disc 2 and fixed by dripping glue. The serial number 1 is the water feeder shell, and the number 3 is the split eccentric sleeve. The two-and-a-half tiles are fastened on the journal 9 of the special rhinestone main shaft 4, and the steel ball 15 preset in two symmetrical steel ball holes is used to transmit torque and position, and the outer edge journal of the split eccentric sleeve is fitted with a drive bearing. 5. Install a plastic water thrower 17 on the left side of the bearing, and fix the eccentric sleeve with a circlip 16. The driving bearing 5 pushes the ejector rod 25 during the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com