Construction device and method of double-curved-surface arch-shaped concrete wall

A technology of construction device and concrete wall, which is applied in the fields of formwork/formwork/work frame, on-site preparation of building components, connection of formwork/formwork/work frame, etc. Spatial positioning is cumbersome, difficult to detect and control, etc., to achieve the effects of green operability, easy safety protection, and reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manner of the present invention will be briefly described below in conjunction with the accompanying drawings.

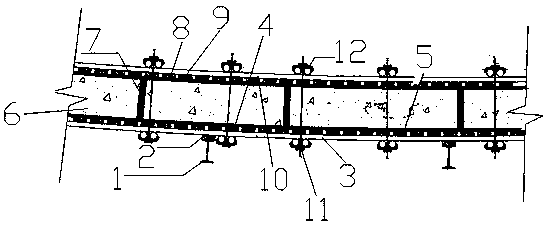

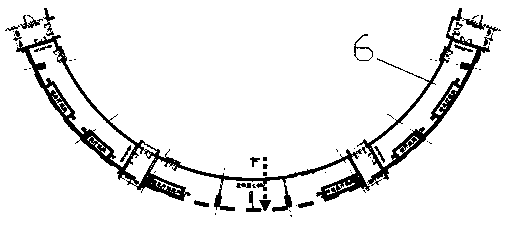

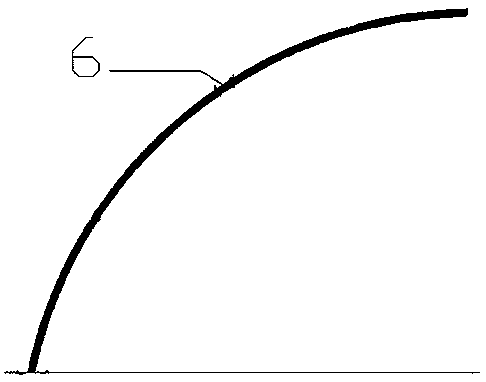

[0033] like Figure 1-3As shown, a construction device for a hyperboloid arc-shaped concrete wall, the hyperboloid arc-shape concrete wall 6 consists of an outer upper curved surface, an inner lower curved surface, a bottom side plane located on the foundation level, and a vertical top The side plane and the vertical planes at both ends are enclosed, and the upper curved surface and the lower curved surface are respectively surrounded by a vertical arc segment located above and a vertical arc segment located below a horizontal arc with a radius on the level of the base horizontal plane The vertical arc segment located above and the vertical arc segment located below have the same center of circle; the construction device comprises a plurality of Arc-shaped steel support 1, the arc shape of multiple arc-shaped steel supports 1 matc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com