Zero-refraction microwave lens based on electromagnetic double resonance structure

A microwave lens and double-resonance technology, applied in the direction of electrical components, antennas, etc., can solve the problem of low antenna gain improvement effect, achieve the effect of reducing the refractive index, good impedance matching characteristics, and reducing the widening frequency band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

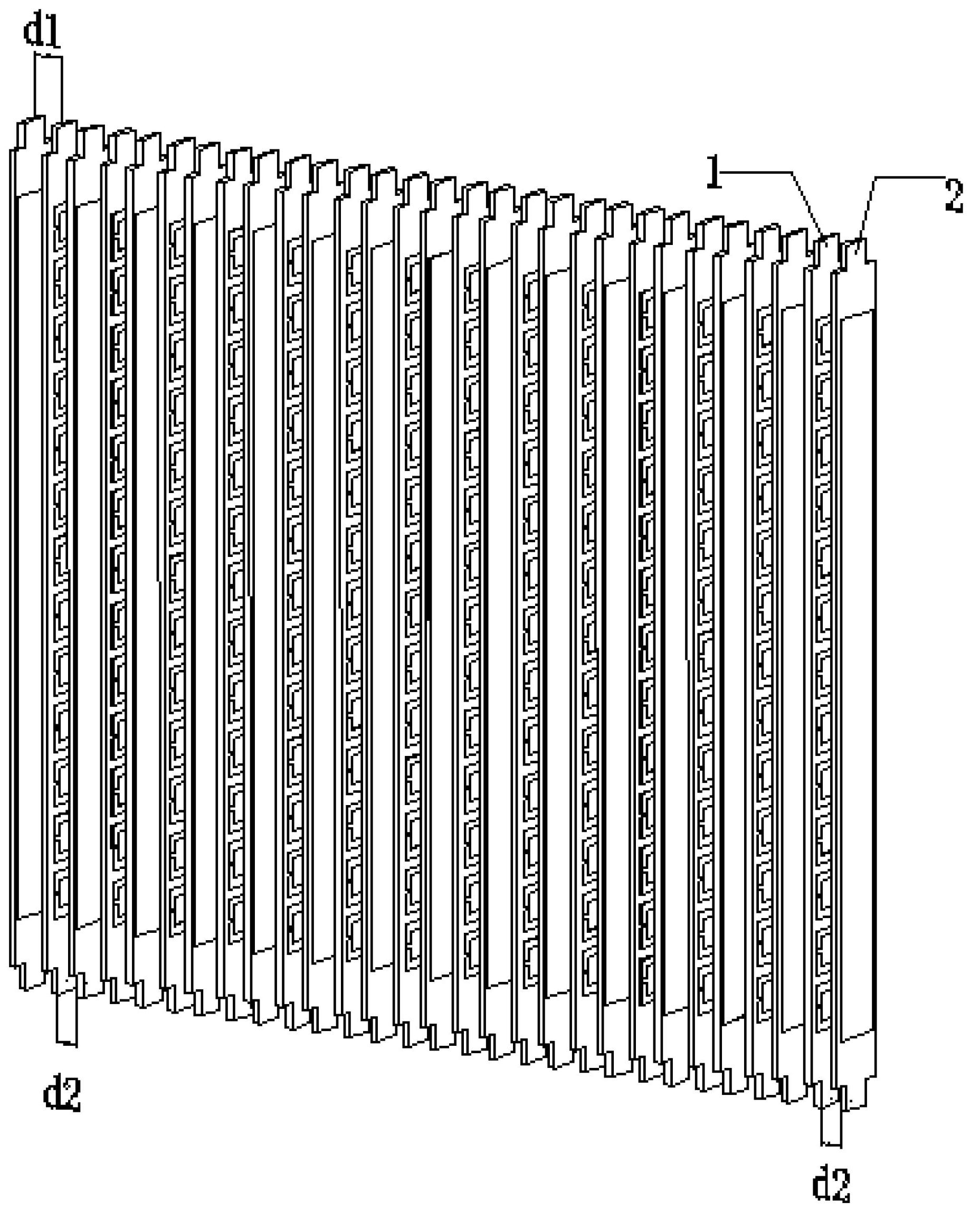

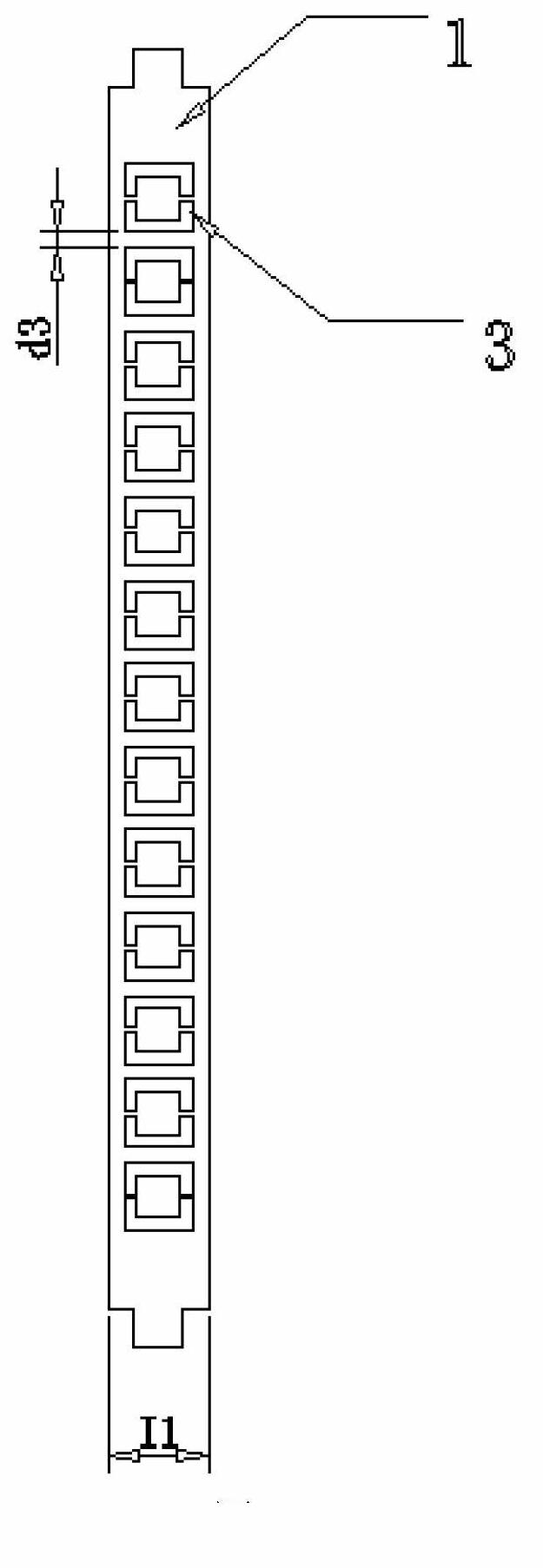

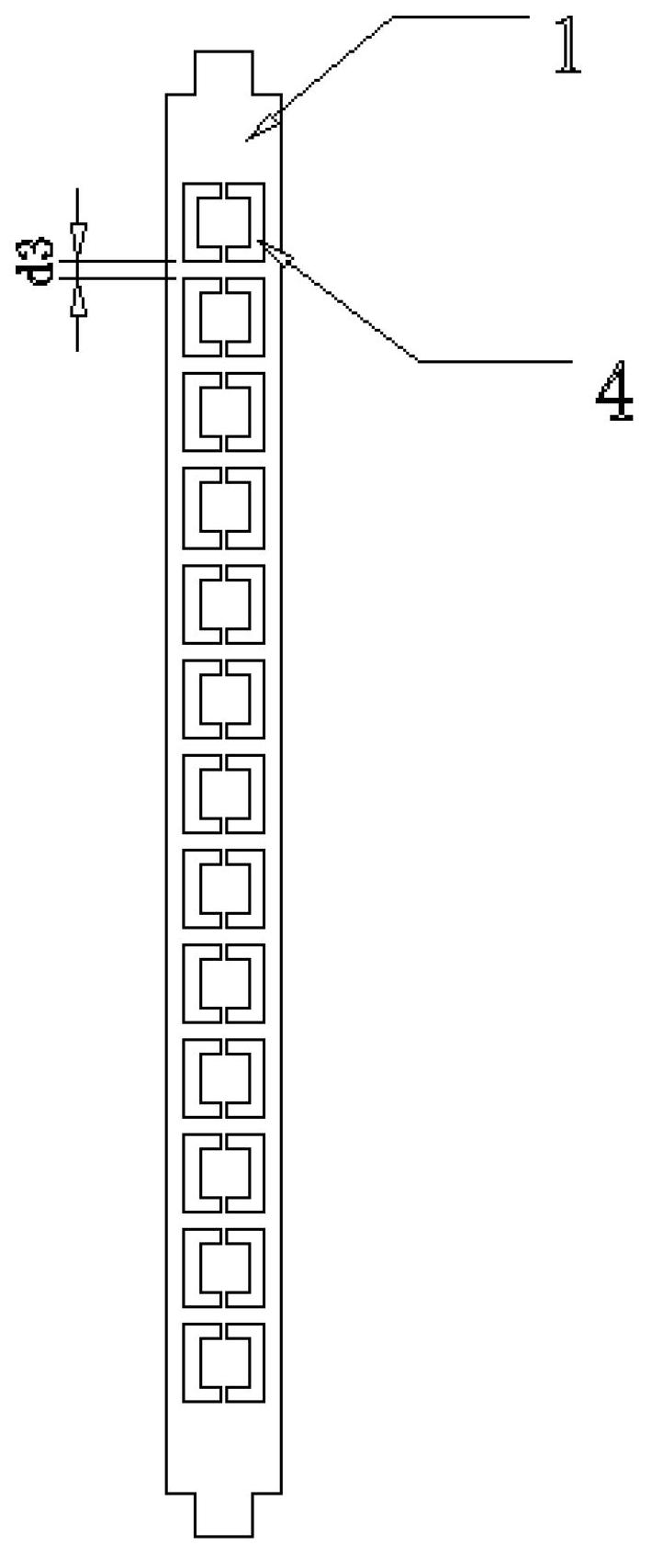

[0020] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 Describe this embodiment, the zero-refraction microwave lens based on the electromagnetic double resonance structure of the present invention, it includes N first strip-shaped dielectric substrates 1 and N+1 second strip-shaped dielectric substrates 2, and N+1 second strip-shaped dielectric substrates 2 Shaped dielectric substrate 2 and N first strip-shaped dielectric substrates 1 are arranged alternately and parallel to each other, and the first strip-shaped dielectric substrate 1 and the second strip-shaped dielectric substrate 2 have the same shape;

[0021] The distances between the adjacent N first strip-shaped dielectric substrates 1 and the N+1 second strip-shaped dielectric substrates 2 are d1, d2, d1, d2...d2 respectively;

[0022] The first strip-shaped dielectric substrate 1 is formed by etching a double-sided copper-clad strip-shaped dielectric substrate...

specific Embodiment approach 2

[0025] Specific implementation mode two: combination figure 2 This embodiment is described. This embodiment is a further description of the zero-refraction microwave lens based on the electromagnetic double-resonance structure described in Embodiment 1. The d1 is 2.9 mm, and the d2 is 3.7 mm.

specific Embodiment approach 3

[0026] Embodiment 3: This embodiment is a further description of the zero-refraction microwave lens based on the electromagnetic double resonance structure described in Embodiment 2. The distance d3 between the adjacent square split resonator rings SRR of the first strip-shaped dielectric substrate 1 is 1.2mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com