Wave-absorbing patch with periodic structure and preparation method thereof

A periodic structure and wave-absorbing patch technology, which is applied in the direction of electrical components, antennas, magnetic field/electric field shielding, etc., can solve the problems of deteriorating low-frequency band absorption performance and reducing the filling amount of soft magnetic powder, so as to achieve the advantages of light weight, Effect of improving impedance matching characteristics and good electromagnetic wave absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

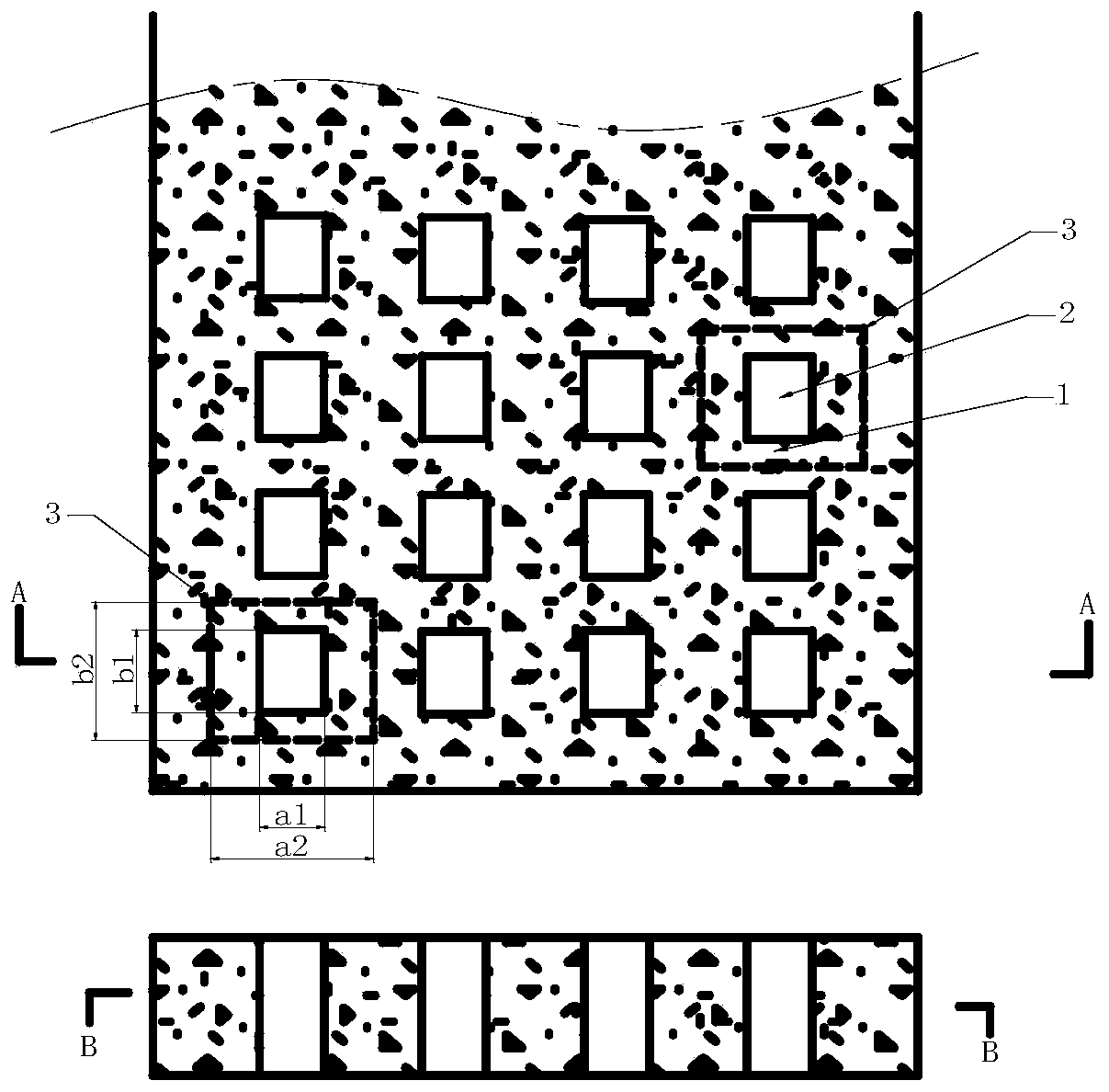

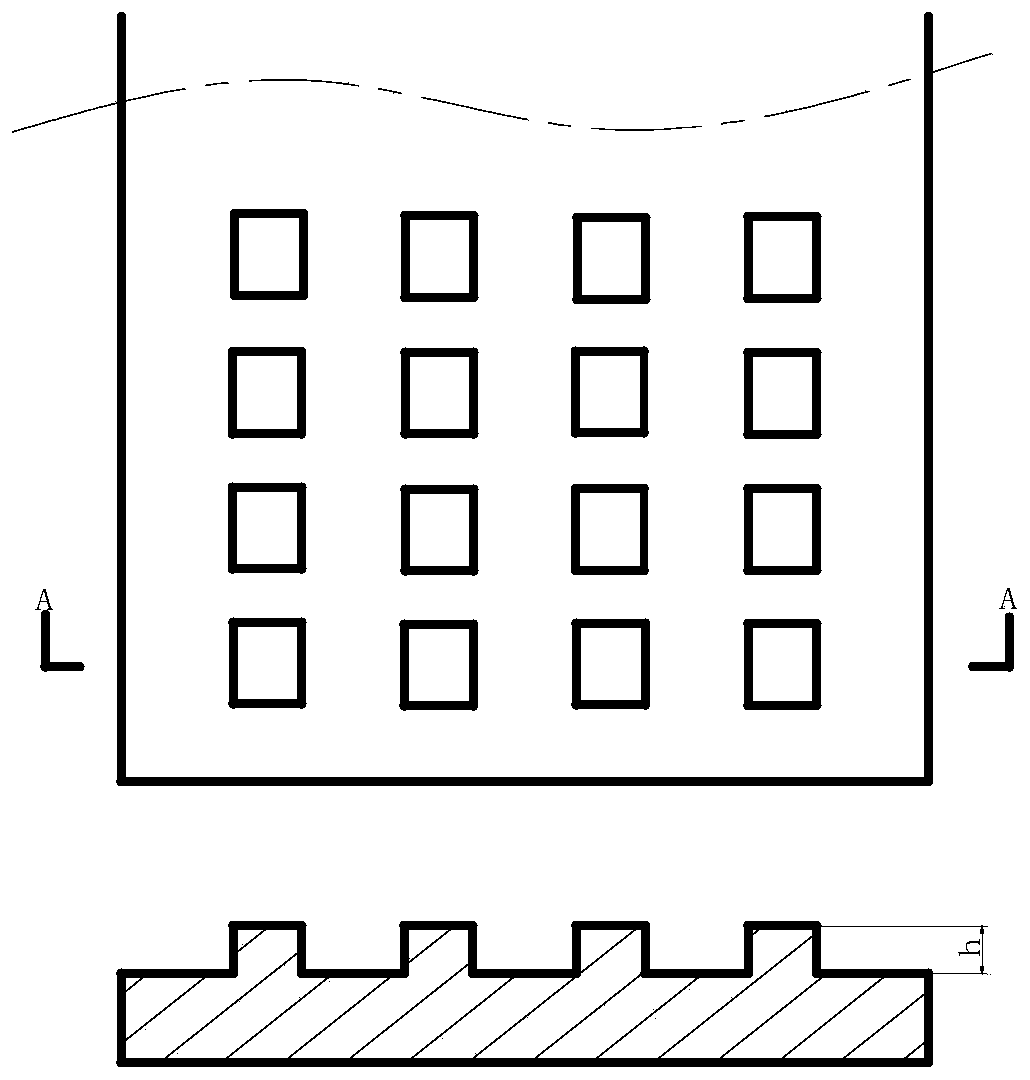

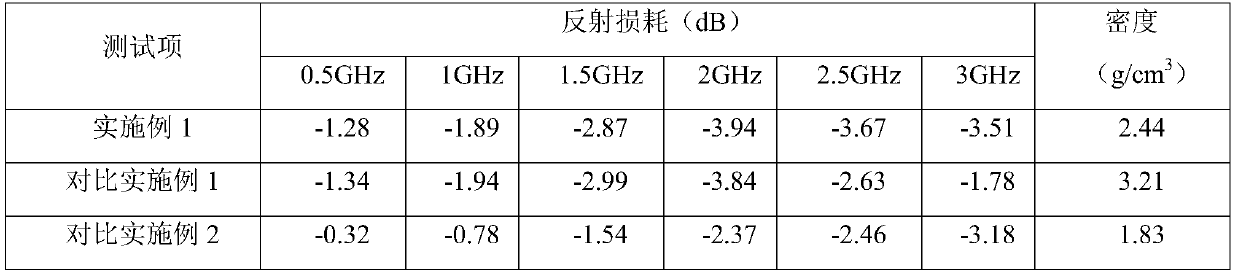

[0055] A wave-absorbing patch with a periodic structure, the wave-absorbing patch with a periodic structure includes a plurality of period units, and each period unit includes two parts: unit 1 and unit 2.

[0056] Among them, the composition and weight percentage of the unit 1 are: polymer binder: 12%, Fe-Si-Al soft magnetic alloy magnetic powder: 69%, carbonyl iron powder: 18.5%, auxiliary materials: 0.5%.

[0057] The polymer binder is polyurethane.

[0058] The appearance of the Fe-Si-Al soft magnetic alloy magnetic powder is scale-like, the average thickness of the magnetic powder is 0.9 μm, the aspect ratio (diameter direction dimension and thickness direction dimension) is 73:1, and the alloy composition (weight percentage) is Fe: 84.6%; Si: 9.3%; Al: 5.4%, impurity elements (including C, O, etc.) 0.7%.

[0059] The shape of the carbonyl iron powder is spherical, the average particle size is 3.2 μm, the composition (weight percentage) Fe=98.7%, and impurity elements (i...

Embodiment 2

[0082] A wave-absorbing patch with a periodic structure, the wave-absorbing patch with a periodic structure includes a plurality of period units, and each period unit includes two parts: unit 1 and unit 2.

[0083] Among them, the composition and weight percentage of unit 1 are: polymer binder: 14%, Fe-Si-Al soft magnetic alloy magnetic powder: 65.4%, carbonyl iron powder: 20.2%, auxiliary materials: 0.4%.

[0084] The polymer binder is polyurethane.

[0085] The appearance of the Fe-Si-Al soft magnetic alloy magnetic powder is scale-like, the average thickness of the magnetic powder is 0.9 μm, the aspect ratio (diameter direction dimension and thickness direction dimension) is 73:1, and the alloy composition (weight percentage) is Fe: 84.6%; Si: 9.3%; Al: 5.4%, impurity elements (including C, O, etc.) 0.7%.

[0086] The carbonyl iron powder has a spherical shape, an average particle size of 1.8 μm, a composition (weight percentage) of Fe=98.4%, and impurity elements (includi...

Embodiment 3

[0102] A wave-absorbing patch with a periodic structure, the wave-absorbing patch with a periodic structure includes a plurality of period units, and each period unit includes two parts: unit 1 and unit 2.

[0103] Among them, the composition and weight percentage of unit 1 are: polymer binder: 12.5%, Fe-Si-Al soft magnetic alloy magnetic powder: 70.6%, carbonyl iron powder: 16.4%, auxiliary materials: 0.5%.

[0104] The polymer binder is polyurethane.

[0105] The appearance of the Fe-Si-Al soft magnetic alloy magnetic powder is scale-like, the average thickness of the magnetic powder is 0.9 μm, the aspect ratio (diameter direction dimension and thickness direction dimension) is 73:1, and the alloy composition (weight percentage) is Fe: 84.6%; Si: 9.3%; Al: 5.4%, impurity elements (including C, O, etc.) 0.7%.

[0106] The carbonyl iron powder has a spherical shape, an average particle size of 1.8 μm, a composition (weight percentage) of Fe=98.4%, and impurity elements (inclu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com