Sm-doped modified quickly-quenched FeSiAl magnetic metal wave-absorbing material and preparation method thereof

A technology of wave absorbing material and magnetic metal, applied in the direction of inorganic material magnetism, inductance/transformer/magnet manufacturing, magnetic field/electric field shielding, etc., can solve the problem of poor wave absorbing dielectric matching characteristics, and achieve the effect of improving impedance matching characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

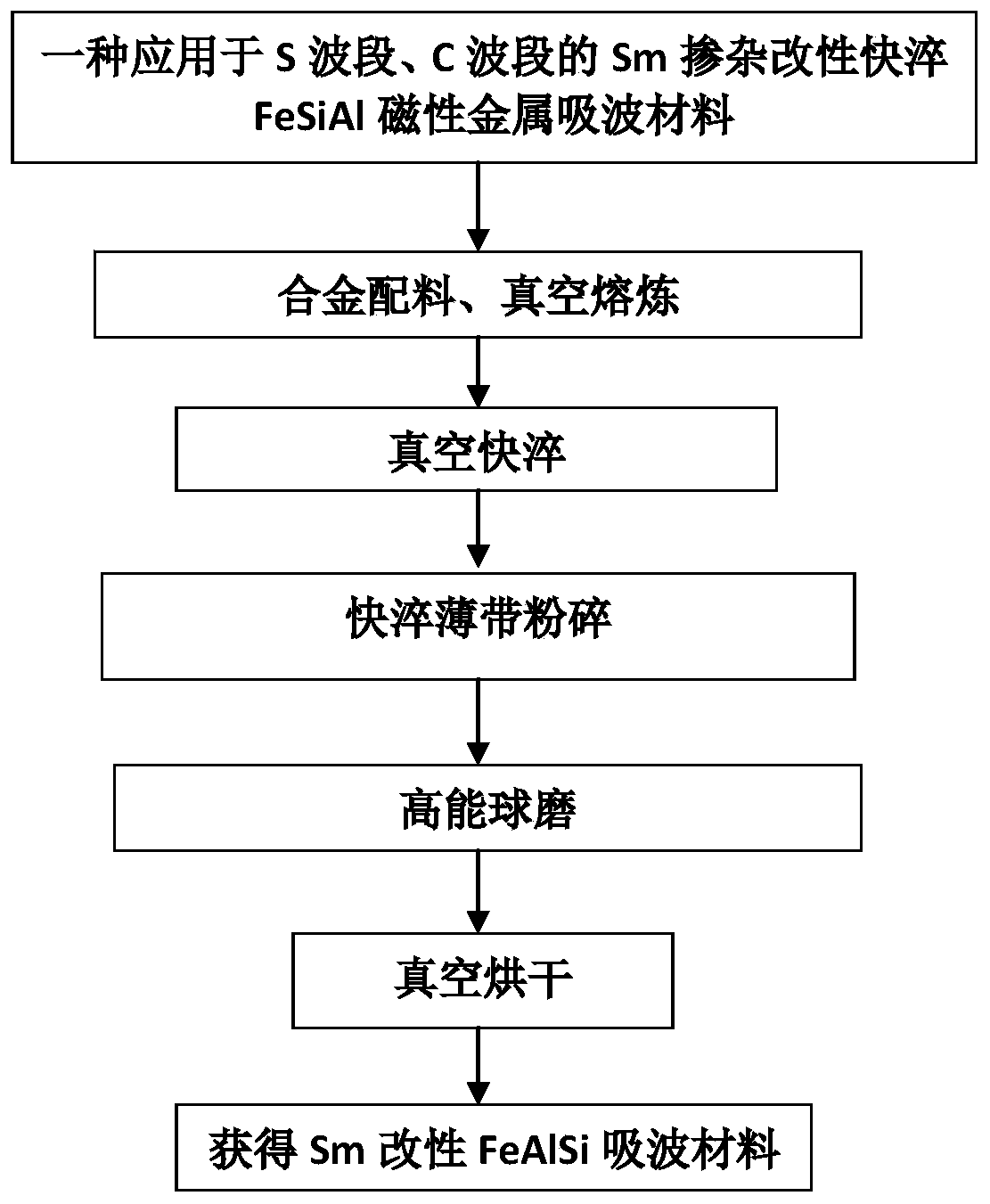

[0044] A Sm-doped modified fast-quenching FeSiAl magnetic metal absorbing material applied to S-band and C-band, comprising the following steps:

[0045] Take high-purity iron (99.99), FeSi alloy (Si 24.99wt% in the alloy), high-purity Al (99.99), rare earth Sm, and the nominal composition of Sm by mole 1 Fe 69 Si 20 al 10 The ingredients, that is, the molar ratio of each element is: Sm: Fe: Si: Al=1:69:20:10, and the total weight is about 40g. Each component is arc smelted in a vacuum smelting furnace. In order to ensure the uniform composition of the smelted alloy, the ingredients need to be smelted three times or more in the vacuum smelting furnace. In the copper crucible in the furnace, the two-stage vacuum system pumps up to 2*10 -3 After Pa, close the vacuum chamber, open the high-purity argon gas pipeline (99.999%) and fill it with high-purity argon gas. After the pressure in the vacuum chamber reaches 0.2Pa, close the vacuum chamber again, and tungsten electrode ar...

Embodiment 2

[0048] A Sm-doped modified fast-quenching FeSiAl magnetic metal absorbing material applied to S-band and C-band, comprising the following steps:

[0049] Take high-purity iron (99.99), FeSi alloy (Si 24.99wt%), high-purity Al (99.99), rare earth Sm, according to the nominal composition Sm 2 Fe 68 Si 20 al 10 Ingredients, that is, the molar ratio of each element is: Sm:Fe:Si:Al=2:68:20:10; the total weight is about 40g. Each component is arc smelted in a vacuum smelting furnace. In order to ensure the uniform composition of the smelted alloy, the ingredients need to be smelted three times or more in the vacuum smelting furnace. The obtained smelting master ingot can properly remove the surface oxide layer, and then put it into the vacuum quenching furnace In the copper crucible, the two-stage vacuum system pumps up to 2*10 -3 After Pa, close the vacuum chamber, open the high-purity argon gas pipeline (99.999%) and fill it with high-purity argon gas. After the pressure in th...

Embodiment 3

[0052] A Sm-doped modified fast-quenching FeSiAl magnetic metal absorbing material applied to S-band and C-band, comprising the following steps:

[0053] Take high-purity iron (99.99), FeSi alloy (Si 24.99wt%), high-purity Al (99.99), rare earth Sm, according to the nominal composition Sm 1 Fe 79 Si 10 al 10 Ingredients, that is, the molar ratio of each element is: Sm:Fe:Si:Al=1:79:10:10; the total weight is about 40-50g. Each component is arc smelted in a vacuum smelting furnace. In order to ensure the uniform composition of the smelted alloy, the ingredients need to be smelted three times or more in the vacuum smelting furnace. In the copper crucible in the furnace, the two-stage vacuum system pumps up to 2*10 -3 After Pa, close the vacuum chamber, open the high-purity argon gas pipeline (99.999%) and fill it with high-purity argon gas. After the pressure in the vacuum chamber reaches 0.2Pa, close the vacuum chamber again, and tungsten electrode arc-melts the mother ingo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com