Wide-angle wave absorbing structure design method based on additive manufacturing

A technology of additive manufacturing and design methods, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve problems such as long production cycle, distortion of wave-absorbing structure performance, narrow absorption angle, etc., and achieve good impedance matching characteristics, The effect of lightweight design and strong imaginary part loss capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The method of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

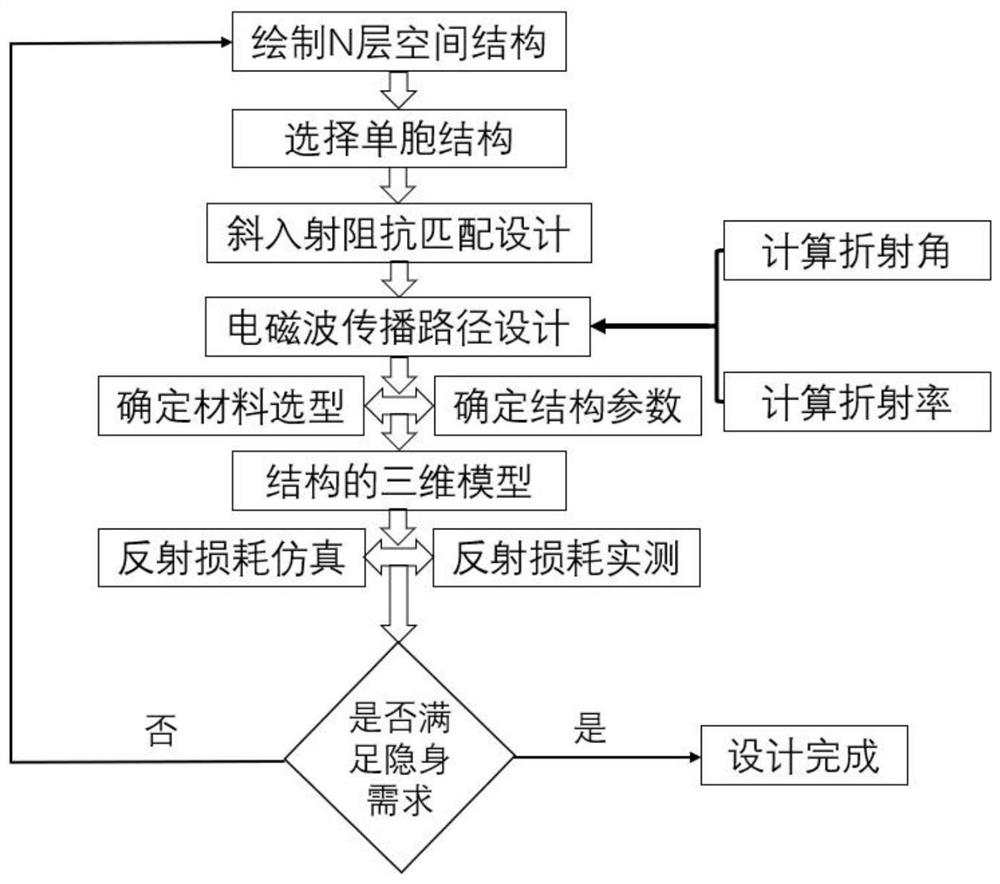

[0036] refer to figure 1, a method for designing a wide-angle absorbing structure based on additive manufacturing, including the following steps:

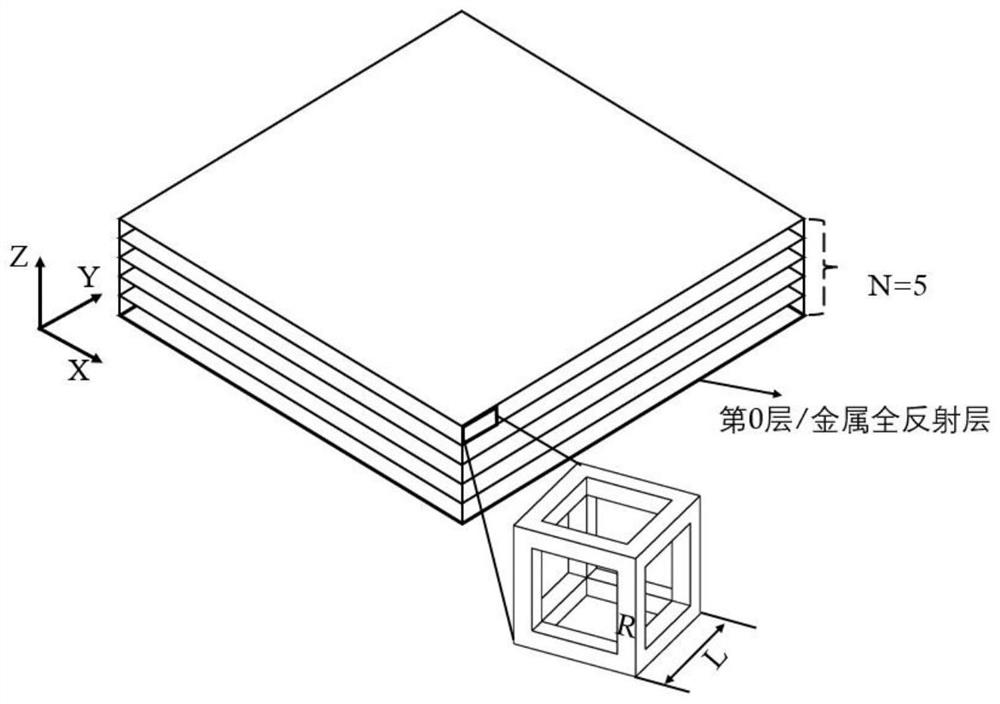

[0037] 1) Refer to figure 2 , according to the shape and size of the stealth target, its size is 180*180*20 millimeters (mm), the structure is divided into 5 layers, the thickness of each layer is 4mm, the bottom layer is a metal total reflection layer, the thickness is not counted, the first ~ 5 layers are impedance matching and loss absorbing layers;

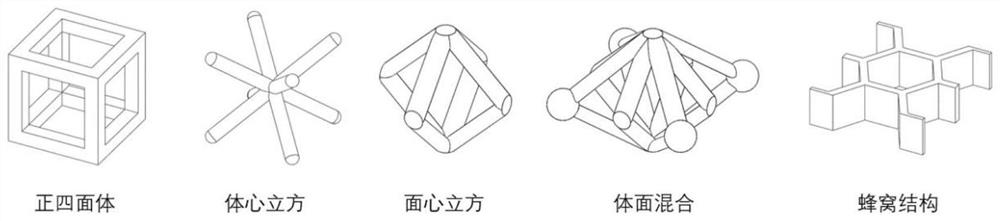

[0038] 2) Refer to image 3 , image 3 It is a schematic diagram of a unit cell structure. The unit cell structure includes a regular tetrahedron, a body-centered cubic, a face-centered cubic, a mixture of decent surfaces, and a honeycomb structure. In this embodiment, the regular tetrahedron structure is selected as the unit cell struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com