Chewing gum base, chewing gum and preparation method of chewing gum

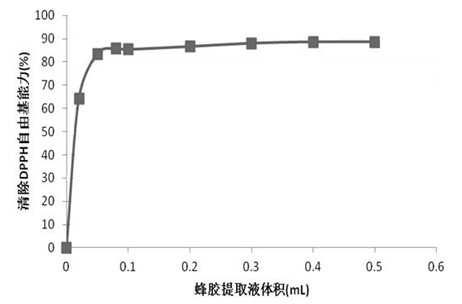

A chewing gum base and chewing gum technology, applied in the directions of chewing gum, food science, application, etc., can solve the problems of inability to swallow chewing gum residue, loss of chewing gum, environmental pollution, etc., achieve good anti-oxidation and scavenge free radicals, and facilitate industrial production , good chewing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

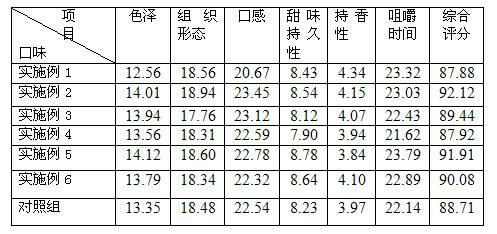

Examples

Embodiment 1

[0023] The chewing gum base is composed of 35 parts of beeswax and 20 parts of gluten by weight.

[0024] The chewing gum containing chewing gum base is composed of 35 parts of beeswax, 2 parts of propolis, 12 parts of xylitol, 20 parts of gluten, 25 parts of water, 4 parts of apple extract and 12 parts of honey in parts by weight.

[0025] Among them, the apple extract was purchased from Changsha Lanwei Biological Products Co., Ltd.

[0026] The preparation method of chewing gum, concrete steps are as follows:

[0027] a. Propolis and beeswax were taken in portions and frozen in a -80°C refrigerator for 4 hours, then pulverized to obtain propolis powder and beeswax powder respectively, and set aside;

[0028] b. The gluten powder is mixed with the beeswax powder obtained in the step a, and then the propolis powder obtained in the step a, xylitol, water, apple extract and honey are added according to the proportioning ratio, and after mixing evenly, the chewing gum is obtai...

Embodiment 2

[0031] The chewing gum base is composed of 30 parts of beeswax and 25 parts of gluten by weight.

[0032] The chewing gum containing chewing gum base is composed of 30 parts of beeswax, 1.5 parts of propolis, 10 parts of xylitol, 25 parts of gluten, 30 parts of water, 6 parts of lemon extract and 10 parts of honey in parts by weight.

[0033] The lemon extract was purchased from Xi'an Runbao Biotechnology Co., Ltd.

[0034] The preparation method of chewing gum, concrete steps are as follows:

[0035] a. Propolis and beeswax were taken in portions and frozen in a -80°C refrigerator for 4 hours, then pulverized to obtain propolis powder and beeswax powder respectively, and set aside;

[0036] b. The gluten powder is mixed with the beeswax powder obtained in the step a according to the portion, and then the propolis powder obtained in the step a, xylitol, water, lemon extract and honey are added according to the proportioning ratio, and after mixing evenly, the granular chewi...

Embodiment 3

[0038] The chewing gum base is composed of 40 parts of beeswax and 15 parts of gluten by weight.

[0039] The chewing gum containing chewing gum base is composed of 40 parts of beeswax, 2.5 parts of propolis, 15 parts of xylitol, 15 parts of gluten, 20 parts of water, 1 part of strawberry extract and 15 parts of honey in parts by weight.

[0040] Strawberry extract was purchased from Changsha Lanwei Biological Products Co., Ltd.

[0041] The preparation method of chewing gum, concrete steps are as follows:

[0042] a. Propolis and beeswax were taken in portions and frozen in a -80°C refrigerator for 4 hours, then pulverized to obtain propolis powder and beeswax powder respectively, and set aside;

[0043] b. The gluten powder is mixed with the beeswax powder obtained in the step a according to the portion, and then the propolis powder obtained in the step a, xylitol, water, strawberry extract and honey are added according to the proportioning ratio, and after mixing evenly,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com