Balsalazide formulations and manufacture and use thereof

A technology of balsalazide and balsalazide disodium, which is applied in the directions of pill delivery, medical preparations without active ingredients, and medical preparations containing active ingredients, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

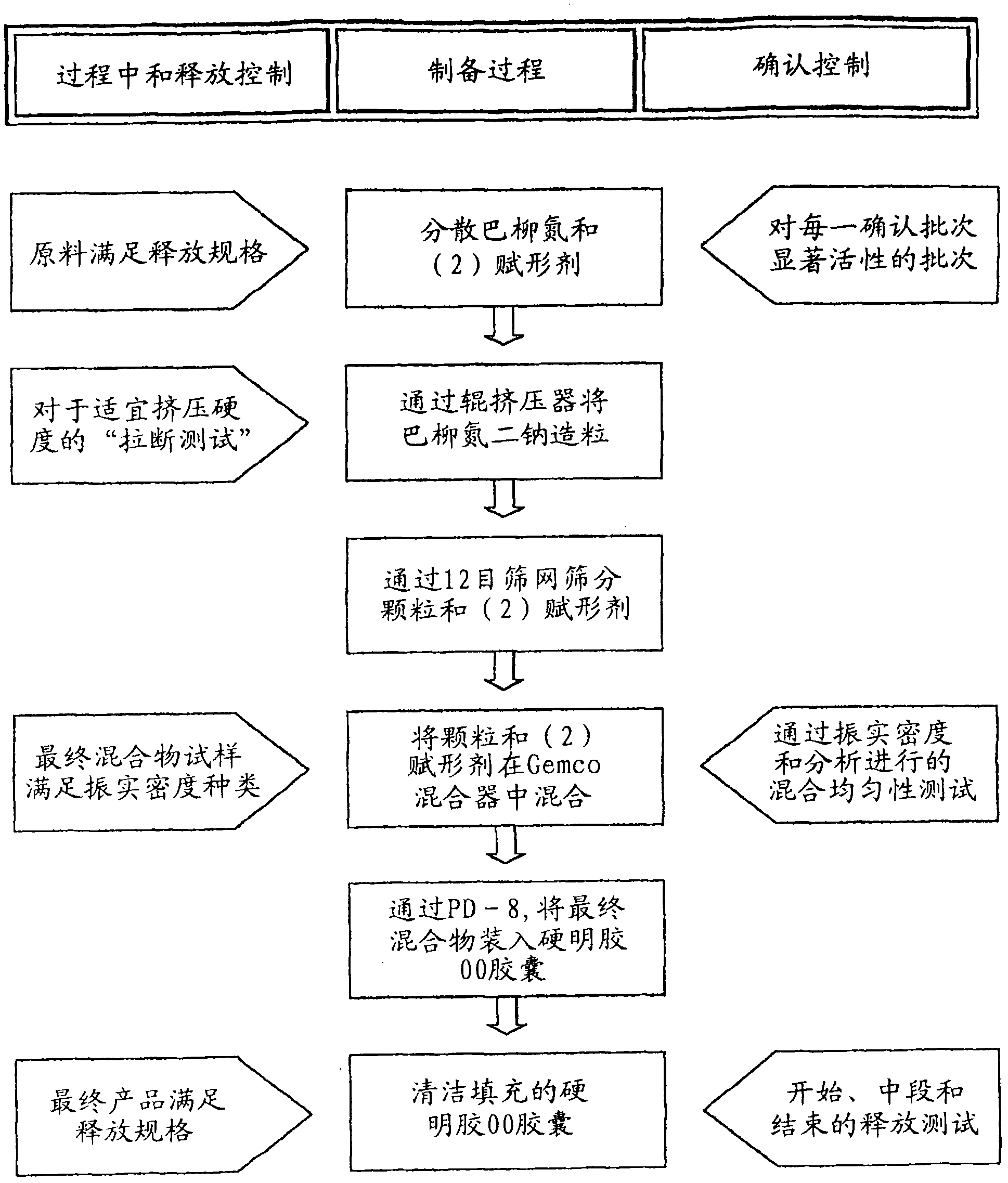

Method used

Image

Examples

preparation example Construction

[0103] The preparation method of balsalazide tablet

[0104] Shown below is an exemplary method of preparing balsalazide tablets:

[0105] initial weighing

[0106] An appropriate amount of balsalazide disodium and other suitable excipients such as hypromellose and magnesium stearate are dispensed.

[0107] wet granulation

[0108] The balsalazide disodium hypromellose was granulated using a low shear (satellite) mixer. The wet granules were tray dried in an oven to a moisture level of about NMT 2.0%.

[0109] to grind

[0110] The dried granules are milled through a Fitzpatrick mill equipped with, for example, a #2AA mesh stainless steel screen with knives advancing at medium speed.

[0111] final mix

[0112] After milling, the compacted granules were charged to a V-blender and blended with magnesium stearate.

[0113] compression

[0114] The final blend was compressed into 1100 mg tablets using an automatic tablet press.

[0115] tablet coating

[0116] The compr...

Embodiment 1

[0153] Colazal Capsules, 750mg Dissolution Test

[0154] Material

[0155] High-purity water (18MΩ resistivity or higher)

[0156] Balsalazide disodium reference standard

[0157] Monobasic Sodium Phosphate, ACS Reagent Grade

[0158] 10N NaOH

[0159] Type 316 Stainless Steel Coil Hood, Laboratory Quality Accessory, Catalog Number: CAPWHT-4S

[0160] Gelman nylon filter, 25mm, 0.2μm pore size, Part No. 4436T

[0161] Vankel 10-µm full-flow filter, part number 17-400

[0162] Specifications (refer to current USP chapter )

[0163] Phase 1 After 30 minutes, each formulation unit must be not less than 75% dissolved (Q=70%)

[0164] Stage 2 After 30 minutes, the average of the 12 formulation units from Stage 1 and Stage 2 must be not less than 70% dissolved. After 30 minutes, each formulation unit must be not less than 55% dissolved.

[0165] Stage 3 After 30 minutes, the average of the 24 formulation units from stages 1, 2 and 3 must be not less than 70% dissolved. Aft...

Embodiment 2

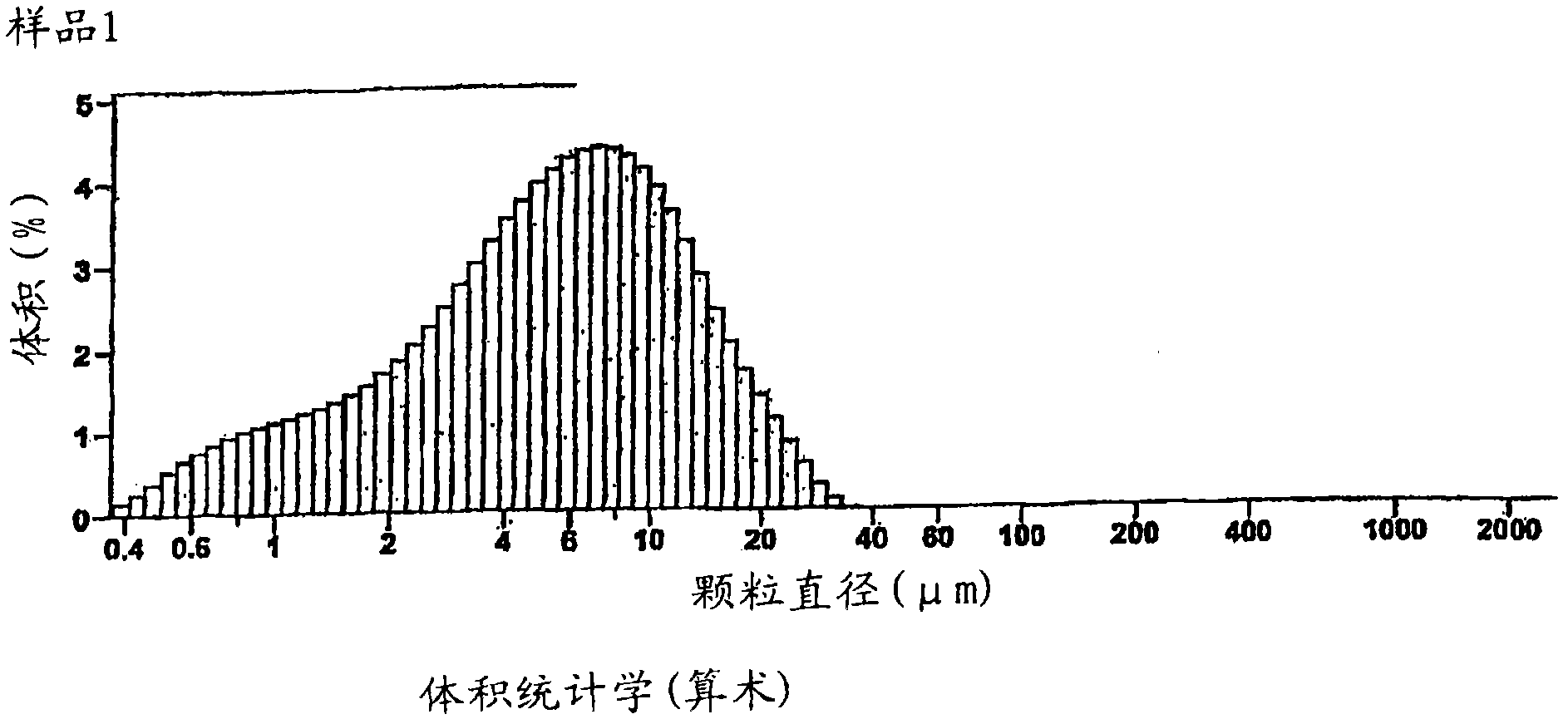

[0209] For the arithmetic statistics of sample 1, figure 2 The data, arithmetic statistics characterizing the surface area, particle size and cumulative volume of a batch of drug (feed material) are shown and tabulated. The particle size distribution of this batch is in figure 2 shown in .

[0210] Sample 1:

[0211] Optical model: Fraunhofer.rfz

[0212] LS 200 small volume module

[0213] Calculation from 0.375μm to 2000μm

[0214] Volume: 100%

[0215] Average: 6.967μm

[0216] Median value: 5.584 μm

[0217] Specific surface area: 19389cm 2 / mL

[0218] %<10 25 50 75 100

[0219] μm 1.266 2.827 5.584 9.624 43.67

[0220] table 5

[0221]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com