Multi-walled carbon nanotube-loaded nano ferroferric oxide catalyst and preparation method and application thereof

A technology of multi-walled carbon nanotubes and ferroferric oxide, which is applied in the field of applied catalysis and the environment, to achieve the effects of improving utilization efficiency, reducing usage costs, and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

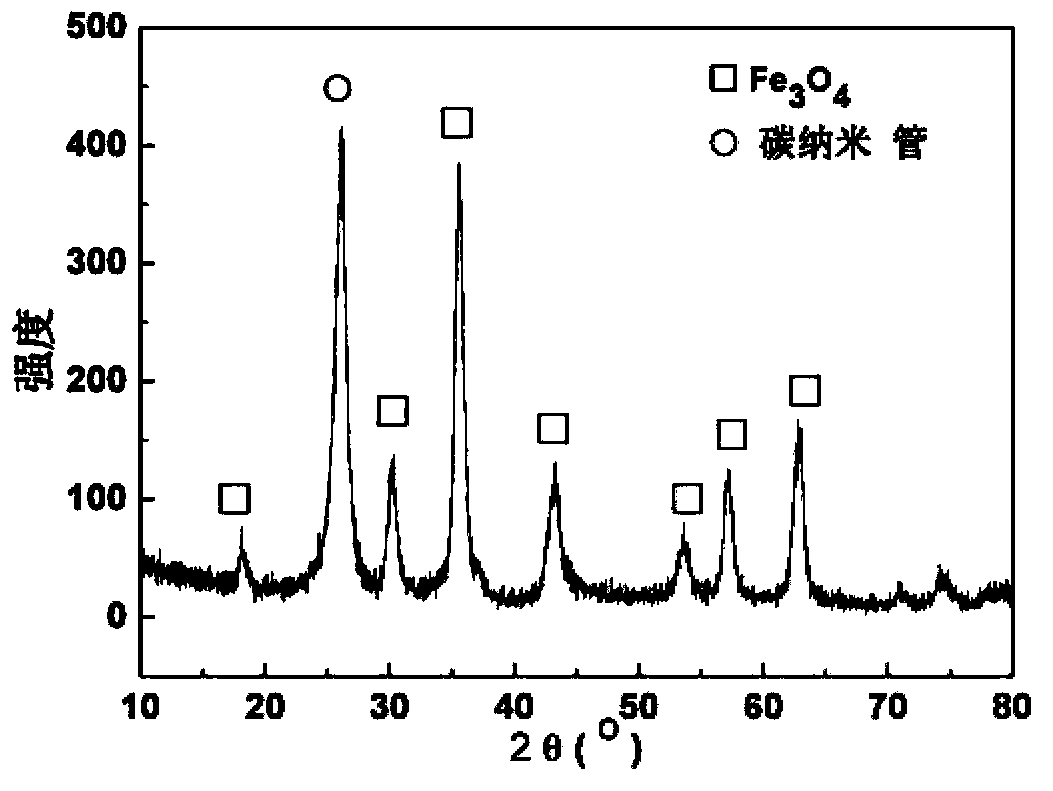

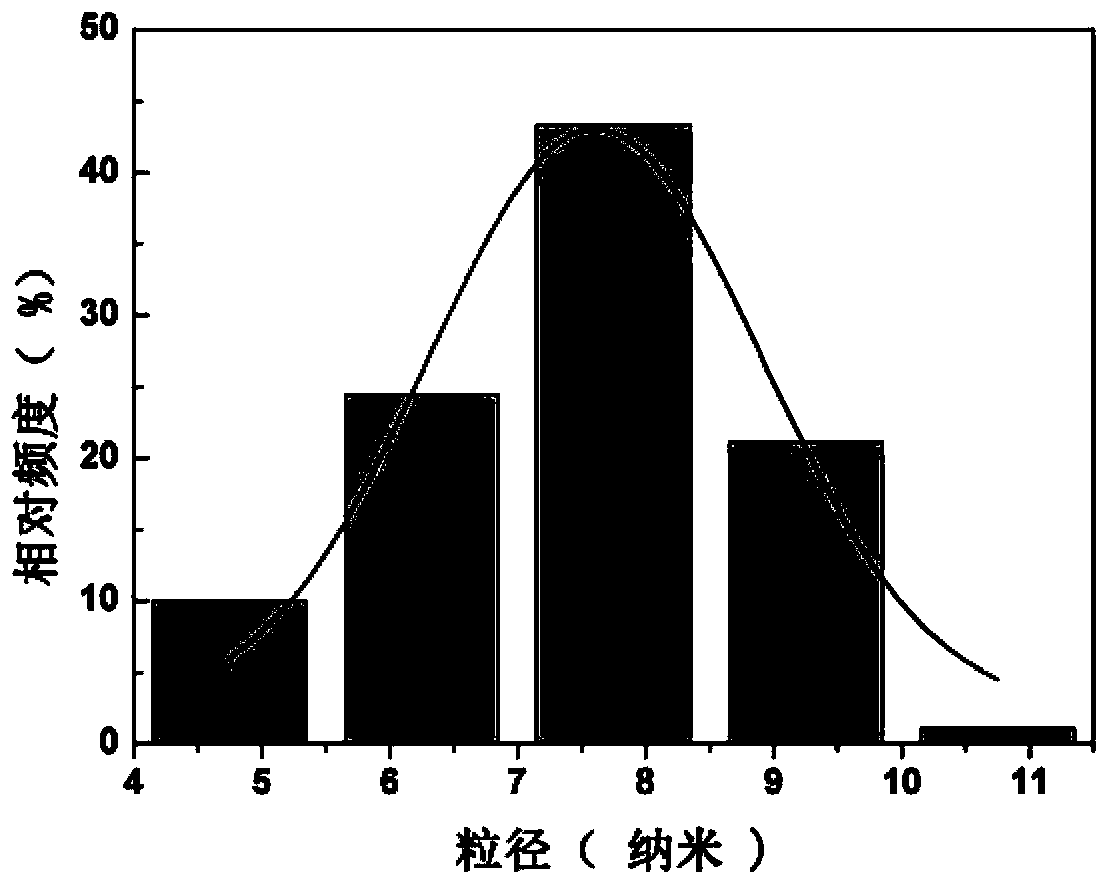

[0048] Embodiment 1, preparation of multi-walled carbon nanotube supported ferric oxide catalyst

[0049] After mixing 10mL of ethylene glycol with 2mL of water, add 0.1g of oxidized MWCNTs, 0.2g of Fe(acac) 3 , and then it was added to a stainless steel autoclave, nitrogen gas was introduced to exclude oxygen, and the lid was sealed. Put the reaction kettle in an oil bath, heat to 200°C at a heating rate of 3°C / min, and react at 200°C for 30 minutes, then continue to heat at a heating rate of 2°C / min to 260°C, and then react at 260°C 30min. After the reaction is completed, take out the reaction kettle from the oil bath and cool it down to room temperature naturally, add ethanol to wash 4-5 times, and vacuum dry at 80°C for 24 hours, that is, the multi-walled carbon nanotubes loaded with iron tetroxide Fe 3 o 4 -MWCNTs.

[0050] Among them, the MWCNTs after the oxidation treatment are prepared according to the following steps: put 2 g of multi-walled carbon nanotube MWCNTs...

Embodiment 2

[0054] Example 2: Fe 3 o 4 -MWCNTs Catalyzed Degradation of Refractory Organic Pollutant Acid Orange II (AOII)

[0055] Fe 3 o 4 -The catalytic activity of MWCNTs was evaluated by the removal efficiency of degrading AOII. In 60mL 0.25mmol / LAOII aqueous solution, at first adjust the pH value to 3.5, then add 500mg / L embodiment 1 to prepare the obtained Fe 3 o 4 - 30mg of MWCNTs, keep the temperature in the water bath and keep stirring. Stir for 30 minutes before the reaction to make the adsorption balance, and then add 1.0mL concentration of 0.9molL -1 The hydrogen peroxide begins to trigger the reaction, and a small amount of mixture is taken out at regular intervals, and after centrifugation, the absorbance of the solution at 484nm is measured by spectrophotometry, and the UV-Vis spectrum changes in the AOII degradation are as follows: Figure 4 shown. According to the calculation formula of AOII removal efficiency:

[0056] D=(C 0 -C t / C 0 )×100% (12)

[0057] ...

Embodiment 3

[0058] Example 3: Fe 3 o 4 -Comparative test of catalytic activity of MWCNTs

[0059] For powder Fe 3 o 4 , Nano Fe 3 o 4 , MWCNTs and Fe 3 o 4 - The catalytic activity of MWCNTs was compared. The same experimental conditions were used to catalytically degrade the AOII solution, and the removal efficiency was compared (the measurement and calculation method was the same as in Example 2). The experimental conditions are: the mass of catalyst in the solution is 500mg / L, the concentration of AOII is 0.25mmol / L, the pH value is 3.5, the H 2 o 2 The concentration is 15mmol / L, and the reaction time is 30min.

[0060] The result is as Figure 5 As shown, it can be seen from the figure that: with Fe 3 o 4 - MWCNTs and other quality powdered Fe 3 o 4 , Nano Fe 3 o 4 , the removal efficiencies of AOII were 15.4%, 37.1%, respectively, while Fe 3 o 4 -The removal efficiency of MWCNTs degraded AOII was 94.3%, and because MWCNTs only adsorbed and did not degrade AOII, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com