Device and method for removing quartz from monocrystalline silicon pot material

A technology of crucible bottom material and silicon crucible, which is applied in the field of removing quartz from single crystal silicon crucible bottom material and the device field of removing quartz from single crystal silicon crucible bottom material, which can solve the problems of slow chemical reaction, slow reaction speed, long reaction cycle, etc. problem, to achieve the effect of improving quality, long service life and shortening reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

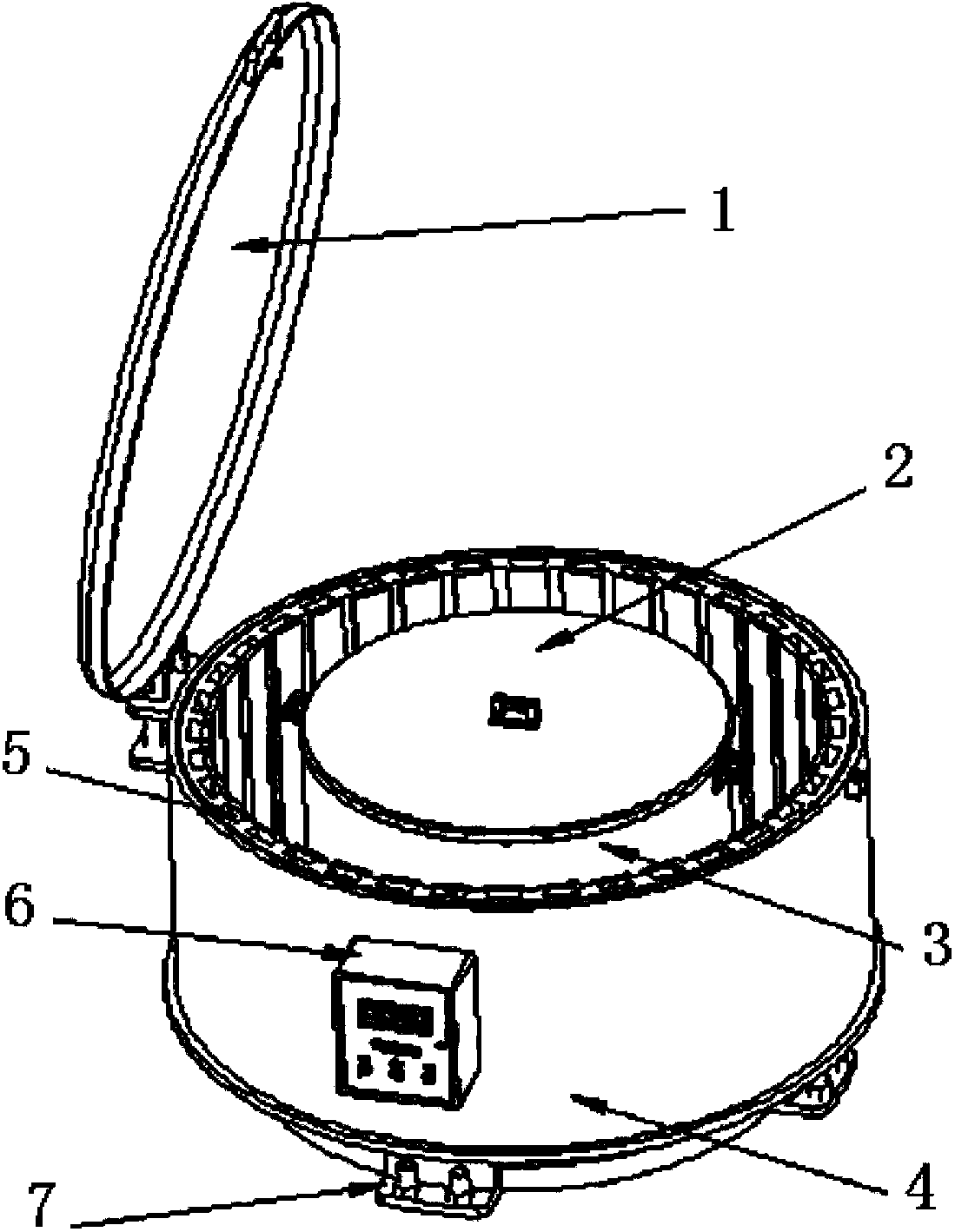

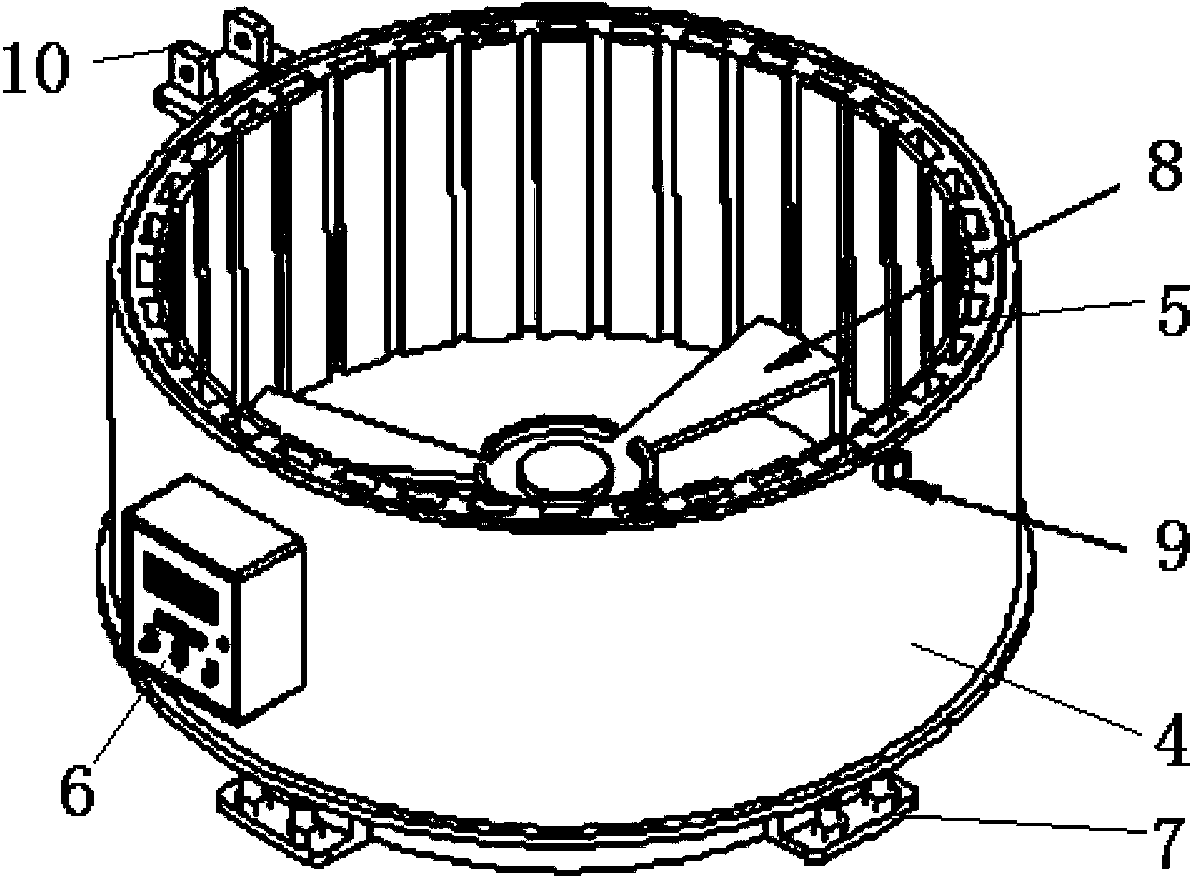

[0026] refer to figure 1 , figure 2 , the present invention is a device for removing quartz in the bottom material of a single-crystal silicon crucible. Control display 6, the temperature control display 6 is connected with the heater 5 through an electric control device, in addition, a water level gauge is also installed on the panel of the temperature control display 6; A reaction kettle 3 is placed on the bottom support 8, and the reaction kettle 3 and the heater 5 are concentrically distributed. There is an upper cover 1 (outer cover), and the reactor 3 is equipped with a reactor cover 2 (inner cover). The reactor cover 2 is a polypropylene plastic cover, which is colorless and transparent and is compatible with the reaction under working conditions. The kettle 3 is sealed and fastened; a base 7 is installed on the outer bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com