Roll gap regulating mechanism

A technology for adjusting mechanism and roll gap, which is applied in the direction of rolling force/roll gap control, metal rolling stand, metal rolling mill stand, etc., which can solve the problem of increasing the quality, increasing the size of the roll box, and reducing the rotation of the eccentric sleeve Angle and other issues, to achieve the effect of long service life of the mechanism, light weight of the box, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

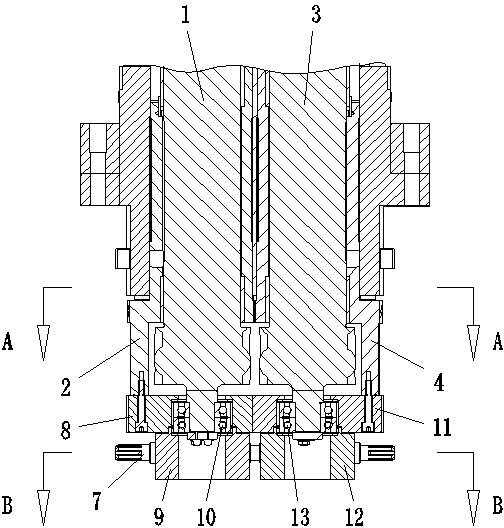

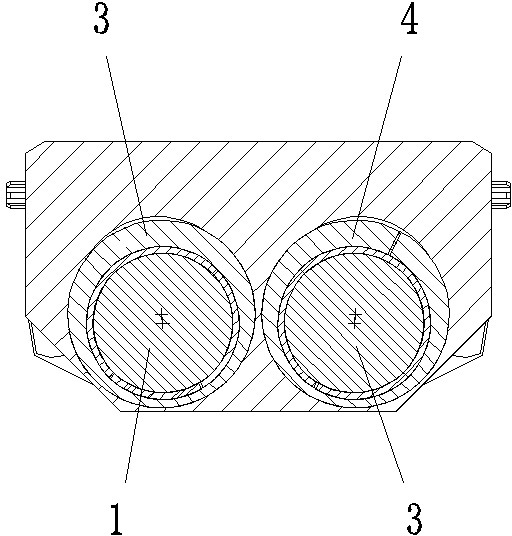

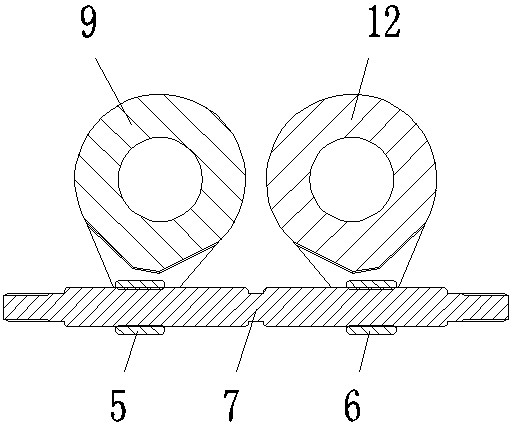

[0013] figure 1 It is a structural schematic diagram of a roll gap adjustment mechanism of the present invention; figure 2 for figure 1 Sectional view along A-A; image 3 for figure 1 Sectional view along B-B; Figure 4 for figure 1 bottom view.

[0014] The roll gap adjustment mechanism in this embodiment includes a first roll shaft 1, a first sleeve 2 that is overlaid on the first roll shaft 1 and is eccentric to it, a second roll shaft 3, and a first sleeve that is overlaid on the second roll shaft 3 and is eccentric to it. Two axle sleeves 4, also comprise the first nut 5, the second nut 6 and the leading screw 7 that is screwed with the first nut 5, the second nut 6 simultaneously, the screw thread that cooperates with the first nut 5 on the described leading screw 7 and The two screw threads that cooperate with the second nut 6 are in opposite directions; the first nut 5 is hinged with the first transmission member that is fixedly fitted with the first sleeve 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com