Water-based solution automatic cleaning device applied to printing device with tin cream adhered to surface

A technology of solder paste printing and surface adhesion, which is applied in the field of automatic cleaning of water-based solutions, can solve problems such as resource depletion, odor inhalation damage, and increased production costs, so as to improve product qualification rate, reduce pollutants, and reduce manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

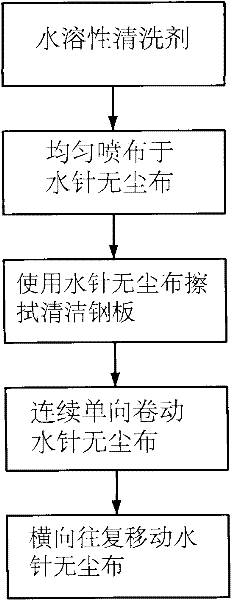

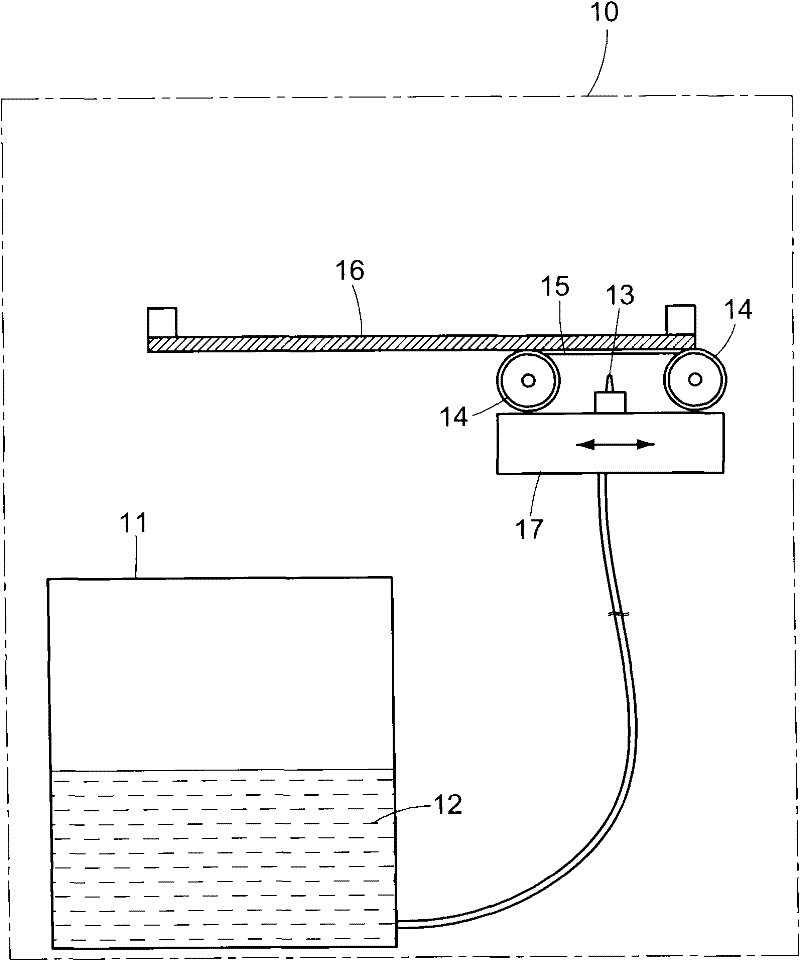

[0028] Please also see figure 1 and figure 2 , the water-based solution automatic cleaning method applied to the surface-adhesive solder paste printing device provided by the present invention mainly includes the following steps: storing 100% water-soluble cleaning solution that does not contain chlorinated solvents and brominated solvents in a solvent tank 11 agent 12; use a nozzle 13 to evenly spray the water-soluble cleaning agent 12 on a continuous one-way scrolling water-needle dust-free cloth 15 conveyed by a roller set 14; and use the water-needle dust-free cloth 15 to wipe clean The steel plate 16 of the solder paste printing device 10 is adhered to this surface.

[0029] The unused water needle clean cloth 15 is wound and stored in one side of the roller, and when the process of wiping the steel plate 16 is carried out, the water needle clean cloth 15 is continuously rolled in one direction by the roller group 14, so that the already The water-needle dust-free clot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com