Inclined wedge block hold-down device for sawtooth material

A technology of a pressing device and a wedge block, which is applied in the direction of auxiliary devices, sawing machine tool manufacturing, metal sawing equipment, etc., can solve the problem of easy wear and consumption of the upper clamping block 1, unfavorable accurate positioning and fixing, and inconvenient operation and other problems, to achieve the effect of good positioning and pressing, reliable pressing, and reducing serious waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

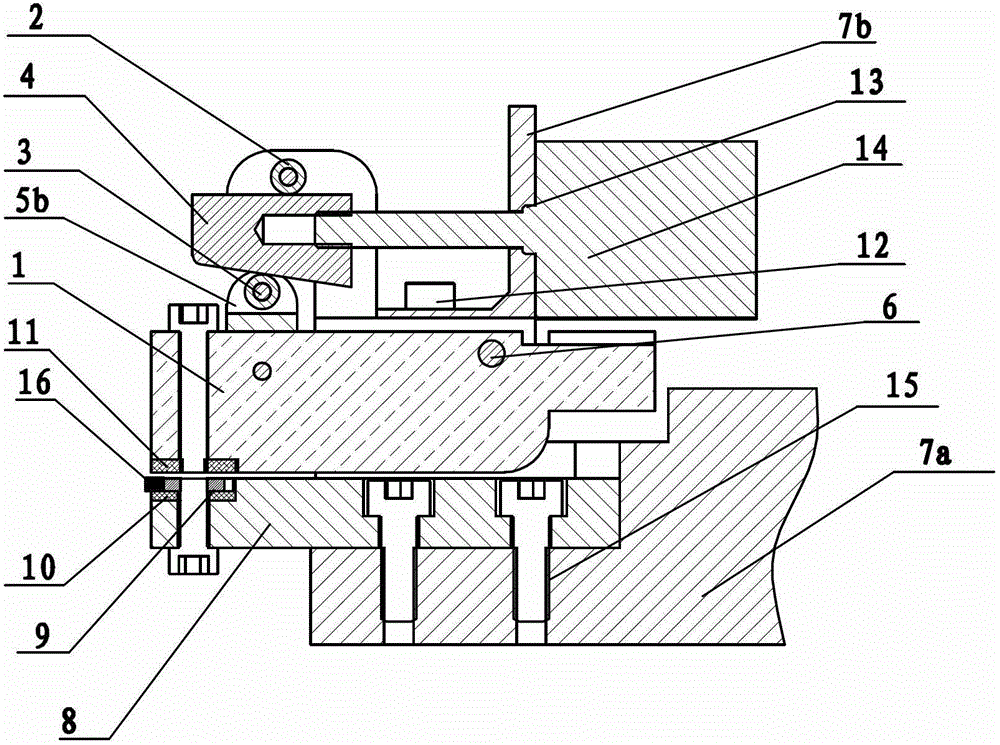

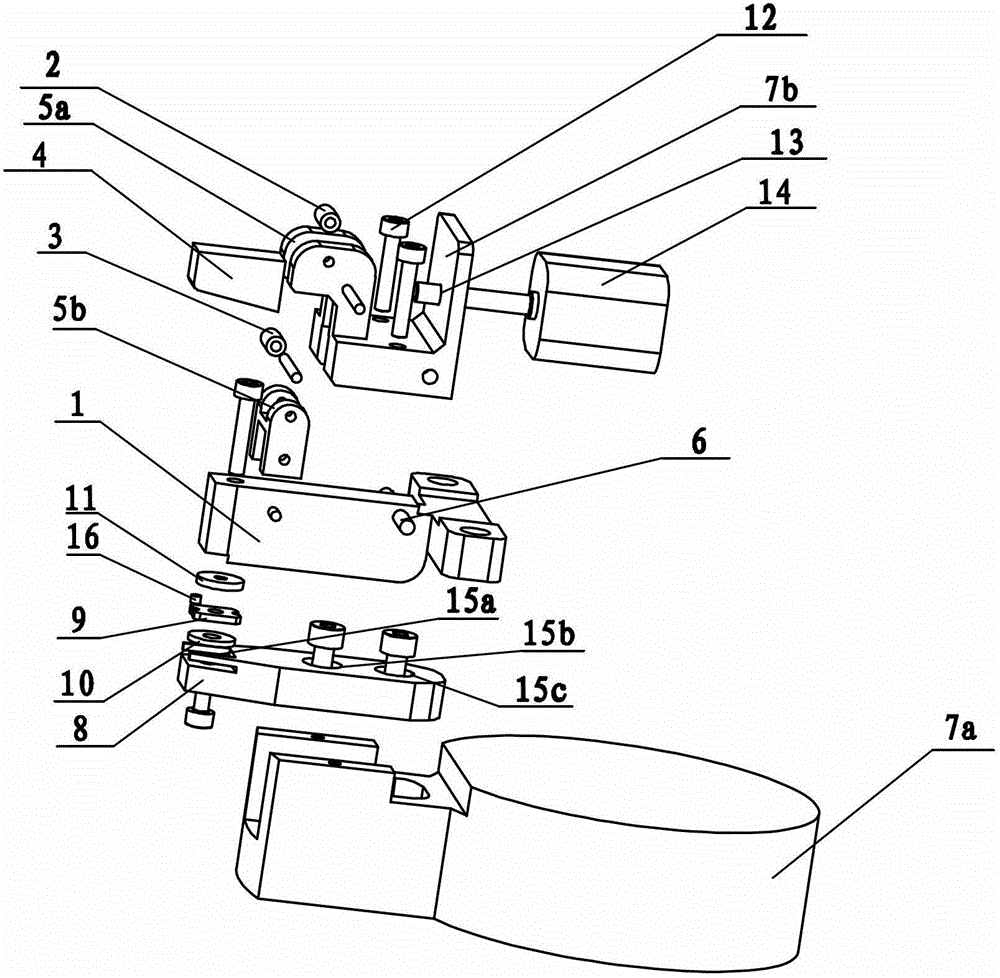

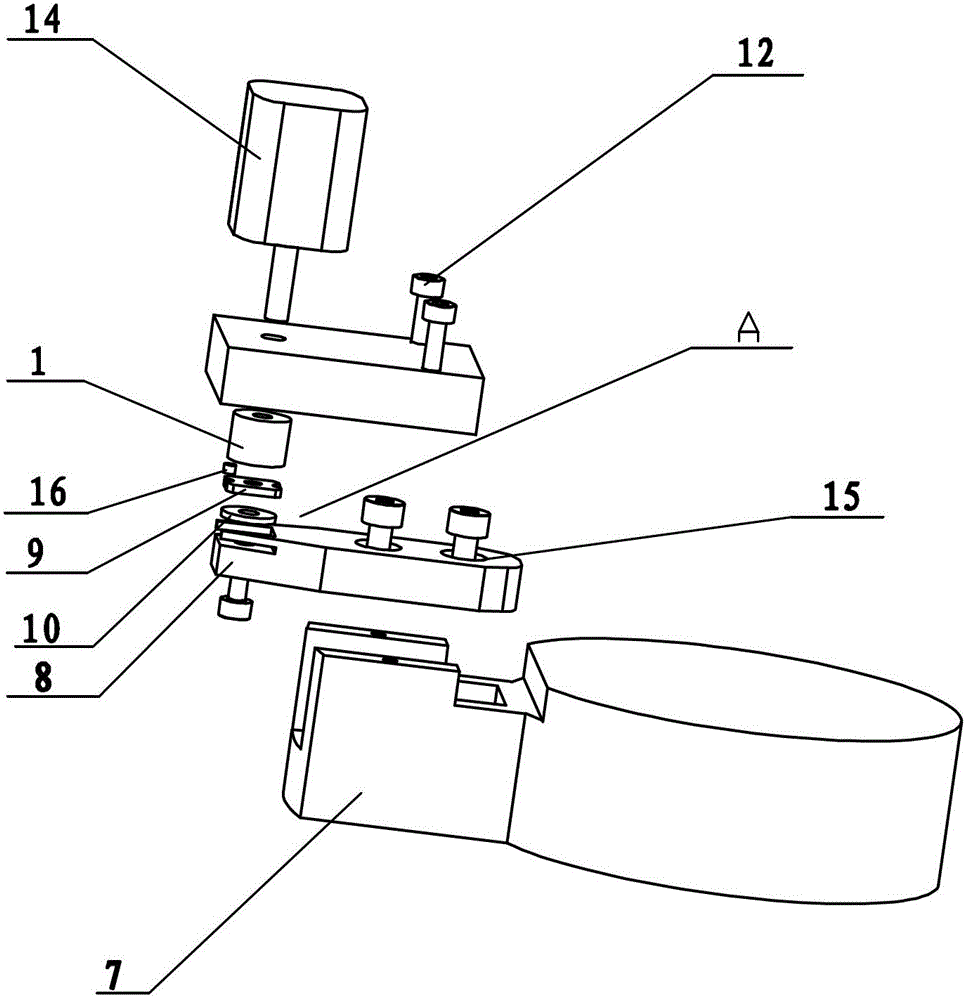

[0024] The specific implementation will be described in detail below in conjunction with the accompanying drawings.

[0025] see figure 1 with figure 2 , the tooth material inclined wedge block pressing device of the present invention includes a base 7, a lower clamping block 8 fixed on the base 7, and an upper clamping block 1 that cooperates with the lower clamping block 8 to clamp the tooth material; The clamping block 1 is hinged with the base 7 through a rotating shaft, and a driving mechanism for driving the upper clamping block 1 to move around the rotating shaft is also provided. A wedge block 4 is fixedly connected, and the wedge block 4 has a slope against the upper clamping block 1 .

[0026] In this embodiment, the lower clamping block 8 can choose a three-dimensional structure such as a cuboid, a cube, etc., as a preferred three-dimensional structure whose upper plane and lower plane are parallel to each other. When the tooth material wedge block pressing devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com