Clamping force setting method and device of injection molding machine

A technology of injection molding machine and setting method, which is applied in the field of mold clamping force setting and mold clamping force setting device of injection molding machine, can solve the problem of difficulty in finding the minimum mold clamping force, trouble, and difficulty in finding the correct value And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

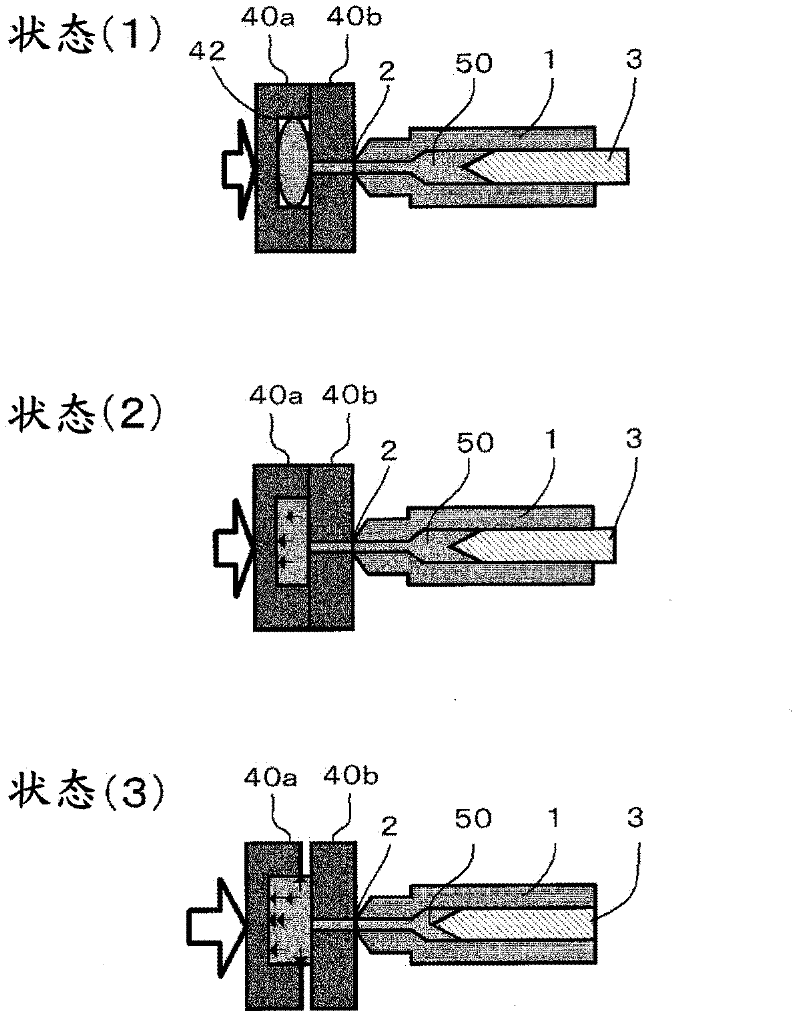

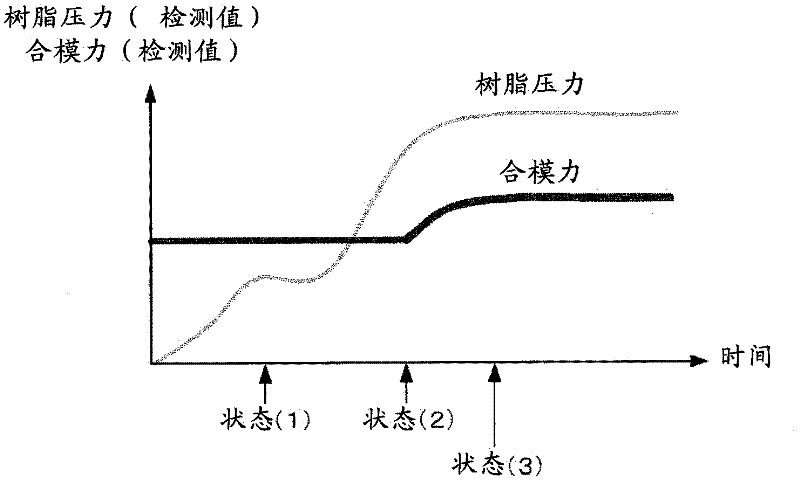

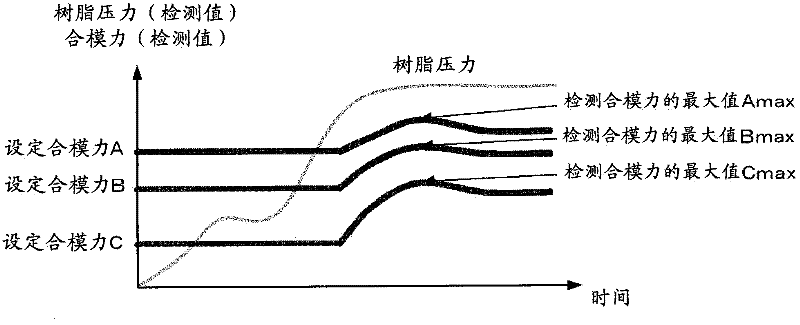

[0032] Figure 4 It is a side view of an injection molding machine capable of setting mold clamping force using the mold clamping force setting method of the present invention.

[0033] The injection molding machine M has a mold clamping unit Mc and an injection unit Mi on a machine base (not shown). The injection part Mi heats and melts the resin material (pellet) and injects the molten resin into the cavity of the mold 40 . The mold clamping part Mc mainly performs opening and closing of the mold 40 (the movable side mold 40a and the fixed side mold 40b).

[0034] First, the injection site Mi will be described. A nozzle 2 is attached to the front end of an injection cylinder 1 , and a screw 3 is passed through the injection cylinder 1 . A resin pressure sensor 5 is provided on the screw 3 , and a load cell or the like that detects the pressure of the resin by the pressure applied to the screw 3 is used. The output signal of the resin pressure sensor 5 is converted into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com