Anti-abrasion high-lubrication additive composite of lubricating oil or engine oil

A technology for lubricating additives and lubricating oils, applied in the direction of lubricating compositions, additives, petroleum industry, etc., can solve problems such as high raw material prices, achieve the effects of saving fuel consumption, reducing noise, and excellent use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

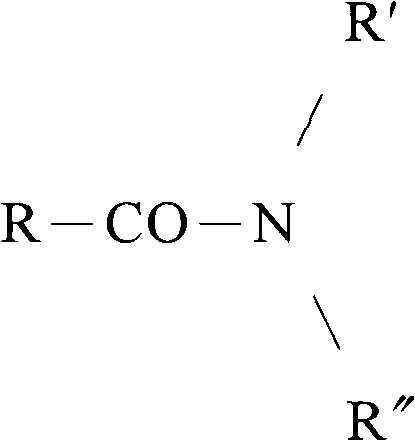

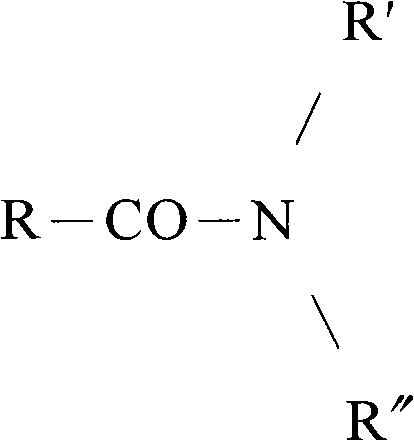

Image

Examples

Embodiment Construction

[0006] In order to make it easy for those skilled in the art to deeply understand the device content of the present invention and the functional benefits that can be achieved, a specific embodiment is now listed, and the detailed description is as follows:

[0007] A lubricating oil, engine oil anti-wear high-lubricating additive composition, mainly in that: every 100 grams contains: nano-zirconia ceramic powder (6-19 grams), alkyl or dimethylbenzene solvent (10-20 grams), Active polyamide wax rheological anti-settling agent (3-6 grams), commercially available lubricating oil or machine oil (55-75 grams). In actual operation, the mixing ratio of additives and engine oil is: 50 grams of additives, 3500 grams (4 liters) of lubricating oil or engine oil.

[0008] Among them, nano zirconia (ZrO 2 ) Ceramic powder has excellent physical and chemical properties such as high hardness, high strength, high toughness, extremely high wear resistance and chemical corrosion resistance, wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com