Melt delivery pipeline system for melt direct-spinning process

A technology of conveying pipeline and melt direct spinning, which is applied in the direction of feeding solution to spinneret, etc., can solve problems such as melt temperature fluctuation, and achieve the effects of improving yield, increasing economic benefits and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

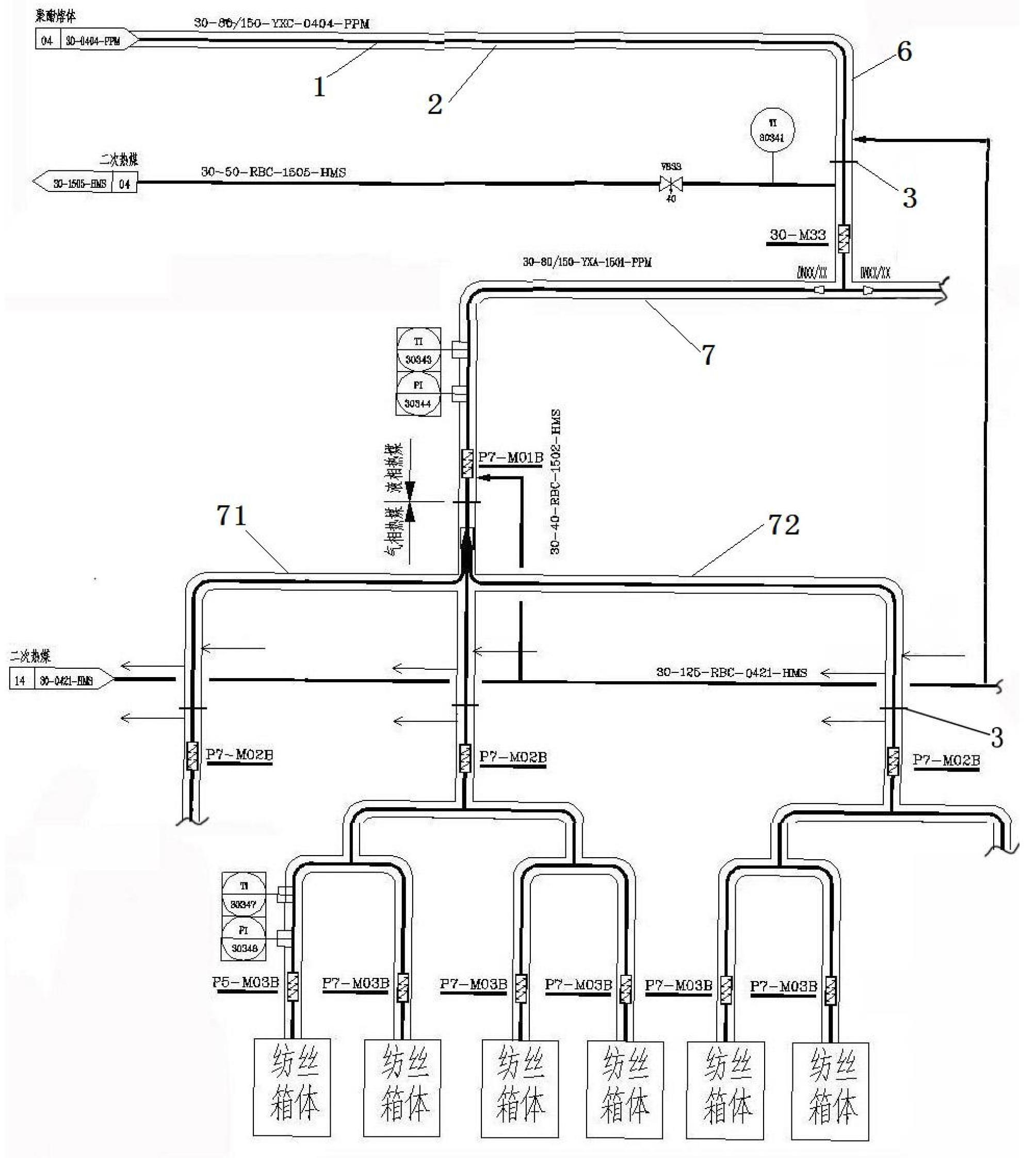

[0030] The present invention can be applied to 24 filament production lines. The melt from the polyester final polymerization tank is sent to the melt distribution three-way valve of the filament device after passing through the melt cooler and the melt filter, and is divided into two branch pipes. Each branch pipe is divided into three branch pipes by distributing the four-way valve, and each branch pipe is further divided into two branch pipes through the distribution three-way valve, and each branch pipe is finally distributed to two spinning boxes through the three-way valve, so that , The melt from the polyester final polymerization tank is finally evenly distributed to 24 spinning boxes for spinning operations.

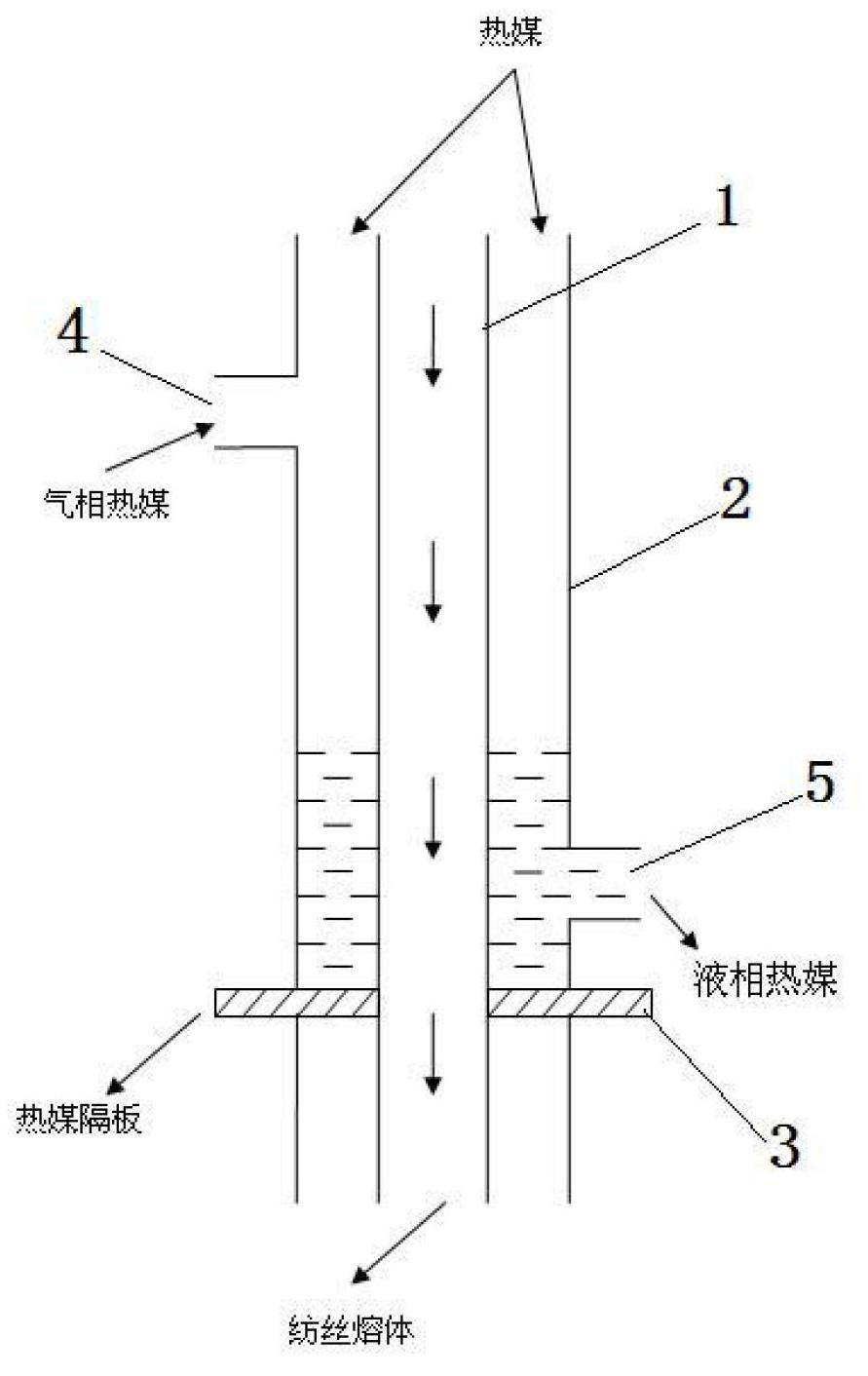

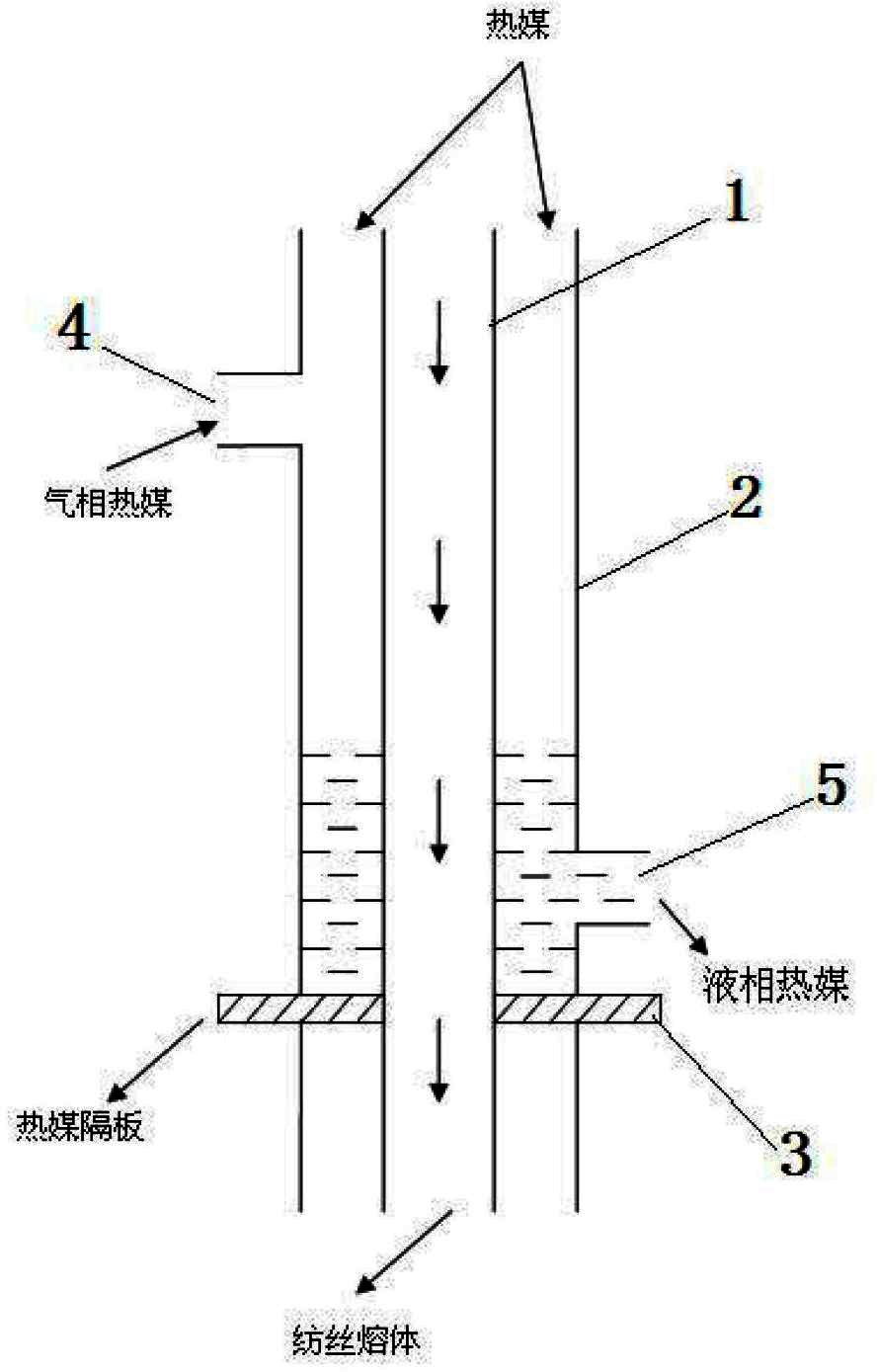

[0031] A heat medium jacket is installed outside the entire PET melt pipe, and the balanced flow of heat medium inside is used to ensure the stability of the melt temperature. The horizontal height of the liquid-phase heat medium collection tank is 5-6m, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com