Stations of open-end rotor spinning machines

A technology of rotor spinning and free end, which is applied in the direction of free end spinning machine, spinning machine, continuous winding spinning machine, etc. It can solve the problems of long positioning duration, adverse effects of power consumption, and hindrance of cross-winding bobbin changeover. Canister cleaning and other issues, to achieve the effect of low structural cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

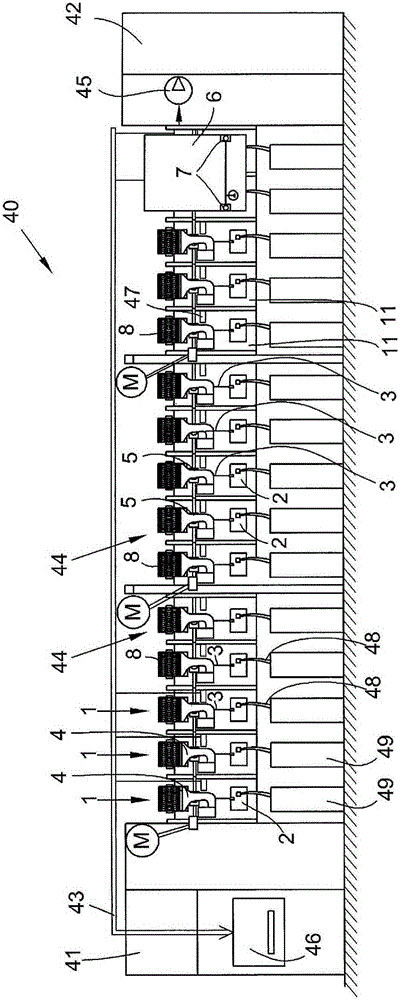

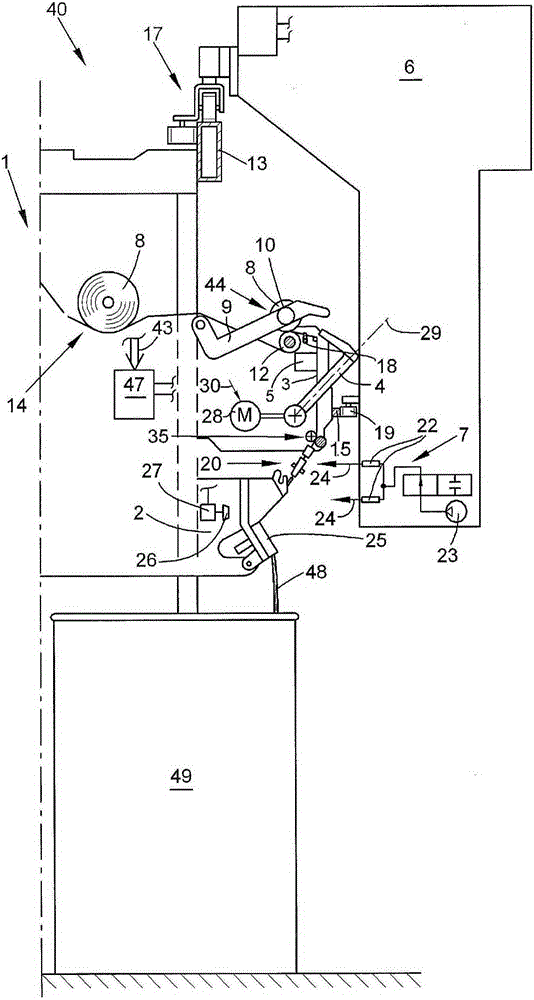

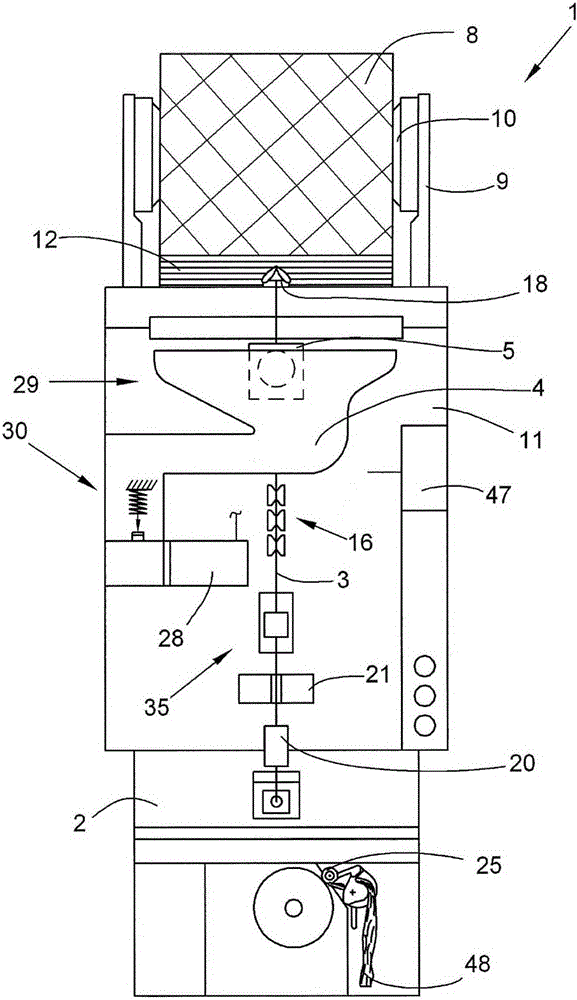

[0025] figure 1 A front view is shown schematically of an open-end rotor spinning machine 40 with end frames 41 , 42 and a plurality of self-contained workstations 1 of the same type arranged between the end frames 41 , 42 .

[0026] As usual, the textile machine's own vacuum source 45 , the power supply and the central control unit 46 of the free-end rotor spinning machine 40 are provided, for example, on the end frame 41 or 42 . The central control unit 46 itself is preferably connected via a bus system 43 to a workstation computer 47 of the individual workstations 1 .

[0027] A large number of stations 1 each have a station housing 11 containing an open-end spinning device 2 , a winding device 44 , a suction nozzle 4 and other known yarn treatment devices, such as a waxing device 5 . On station 1, by means of the free-end spinning device 2, the feed fiber sliver 48 stored in the spinning barrel 49 (which is arranged side by side below the station 1) is spun into a yarn 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com