Adaptive photoelectric electronic yarn cleaner

An electronic yarn clearer, optoelectronic technology, applied in the field of textile machinery control and embedded systems, can solve the problems of complex settings, yarn detection failures, and low detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing.

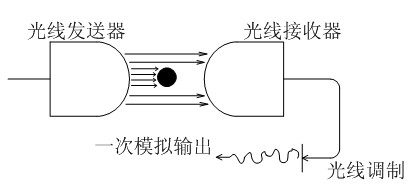

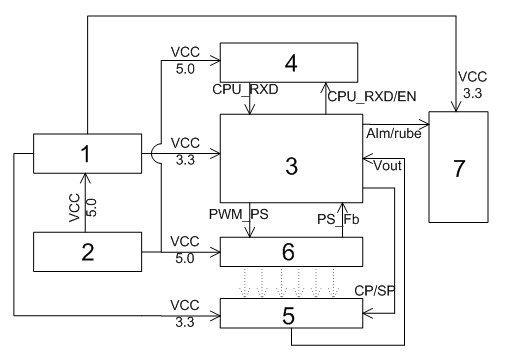

[0034] Specific embodiments of the present invention are shown in the accompanying drawings, figure 1 Shown is the basic principle of optical yarn detection, the yarn to be detected is moved in the area between the light transmitter (LED external light source) and the light receiver (photoelectric sensor), so that the change of the yarn diameter can be Determined by the change in luminous flux received on the light receiver. figure 2 Shown is a schematic block diagram of the structure of the yarn detection circuit, which is mainly composed of the first power module 1, the second power module 2, the control module 3, the RS485 communication module 4, the signal detection module 5, the external light source module 6, and the alarm display operation module Composed of 7.

[0035] The working process of the electronic yarn clearer is as follows: when the yarn passes between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com