Continuous steam explosion device for plant fibers

A plant fiber and steam technology, applied in the direction of raw material separation, can solve the problems of less continuous processing equipment, expensive equipment, and increase the total cost of steam explosion treatment, and achieves strong positive displacement conveying capacity, high-efficiency conveying capacity, and difficult to transport. lingering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

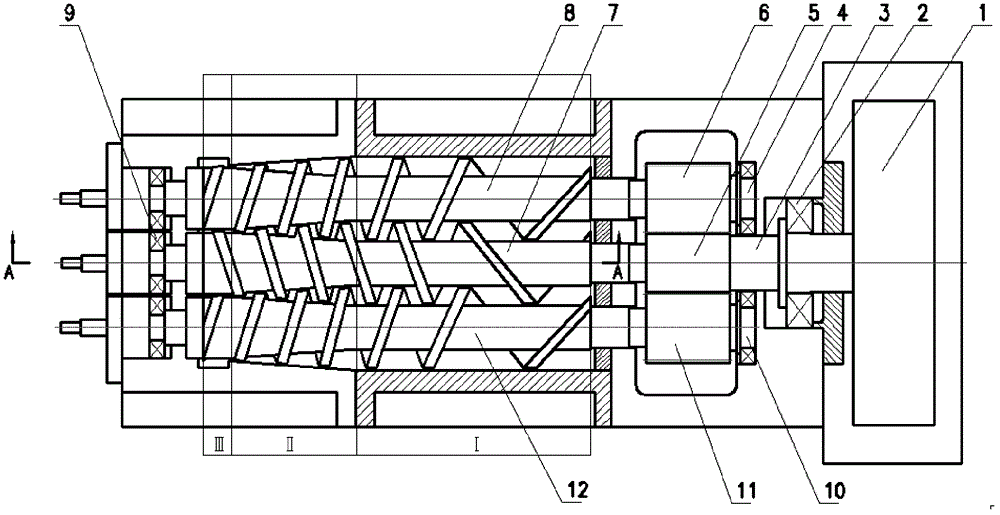

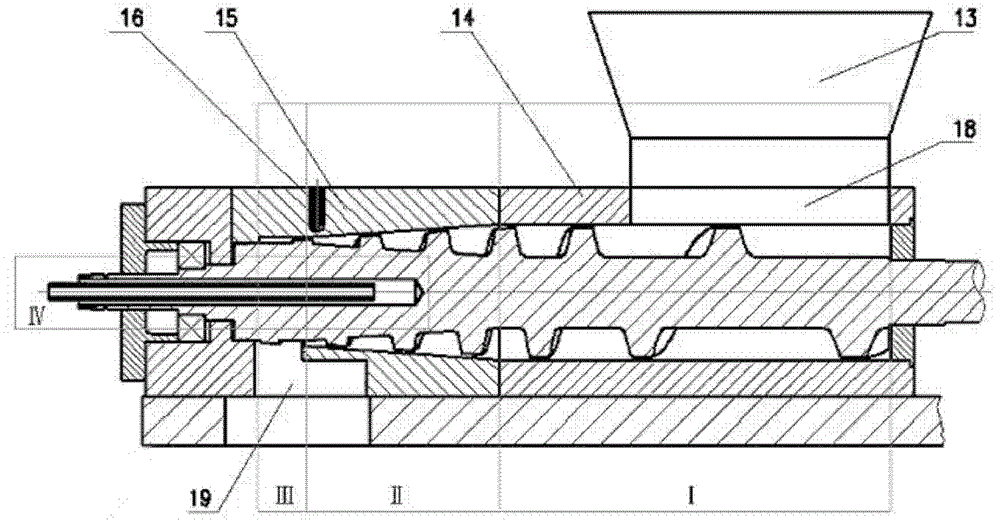

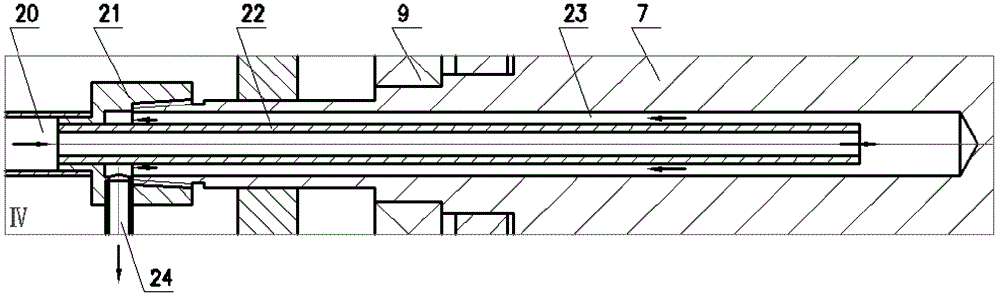

[0025] The continuous steam explosion device for plant fibers of the present invention comprises a sequentially connected material barrel, transmission mechanism and drive mechanism. Such as figure 1 with figure 2 As shown, the barrel 14 is provided with a feed port 18 and a discharge die 15, and the feed port 18 is provided with a hopper 13; The discharge port 19 is vertically downward, and the continuous steam explosion device discharges material along the radial direction of the screw. The geometric shape parameters of the three screws are the same, and the adjacent screws mesh with each other in the radial direction, but the rotation directions of the helices of the adjacent screws are different, and the screw rotation directions are also different. The cross-sectional area of each screw at the end close to the feed port is greater than that at the end close to the discharge port, and has a continuously changing compression ratio. The transmission mechanism includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com