Oil smoke purifier with honeycomb structure

A lampblack purifier and honeycomb structure technology, applied in electrode structure, lampblack removal, household appliances, etc., can solve the problems of low purification efficiency, uneven polarization electric field, damage, etc., and achieve good stability and reliability, and simple structure. Compact, polarizability-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

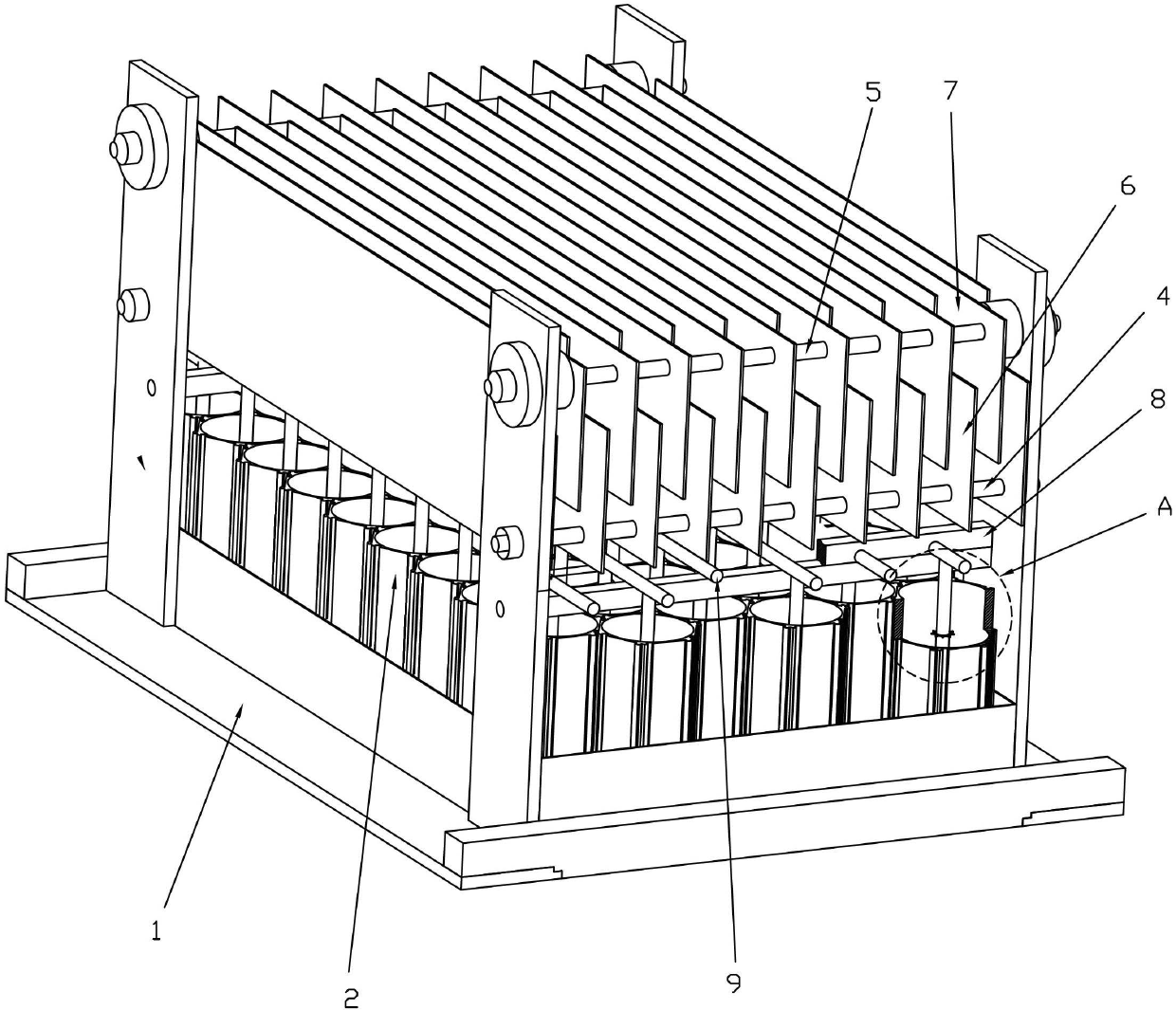

[0016] refer to Figure 1~Figure 7 , an oil fume purifier with a honeycomb structure of the present invention, which includes an insulating box body 1, and positive and negative pole screw rods 4, 5 are erected between the side walls of the insulating box body 1, and the positive and negative pole screw rods 4, 5 Positive and negative plates 6 and 7 are respectively installed on the top, and the positive and negative plates 6 and 7 are arranged at intervals. The lampblack particles polarized by the high-voltage electric field polarization layer are adsorbed to achieve the effect of purifying the lampblack.

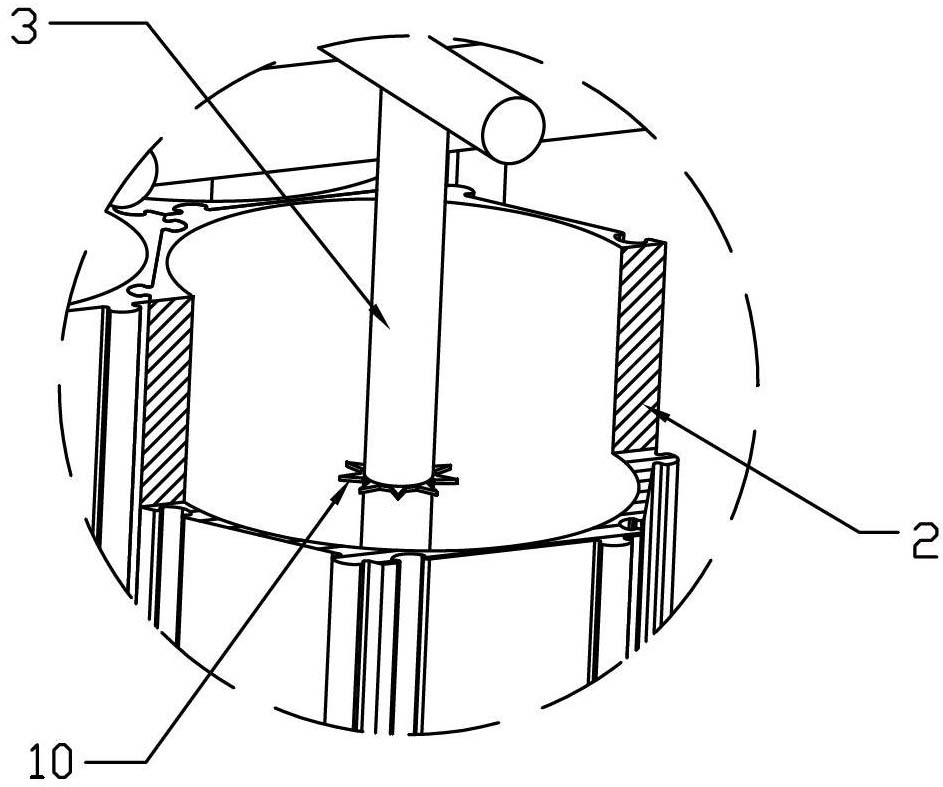

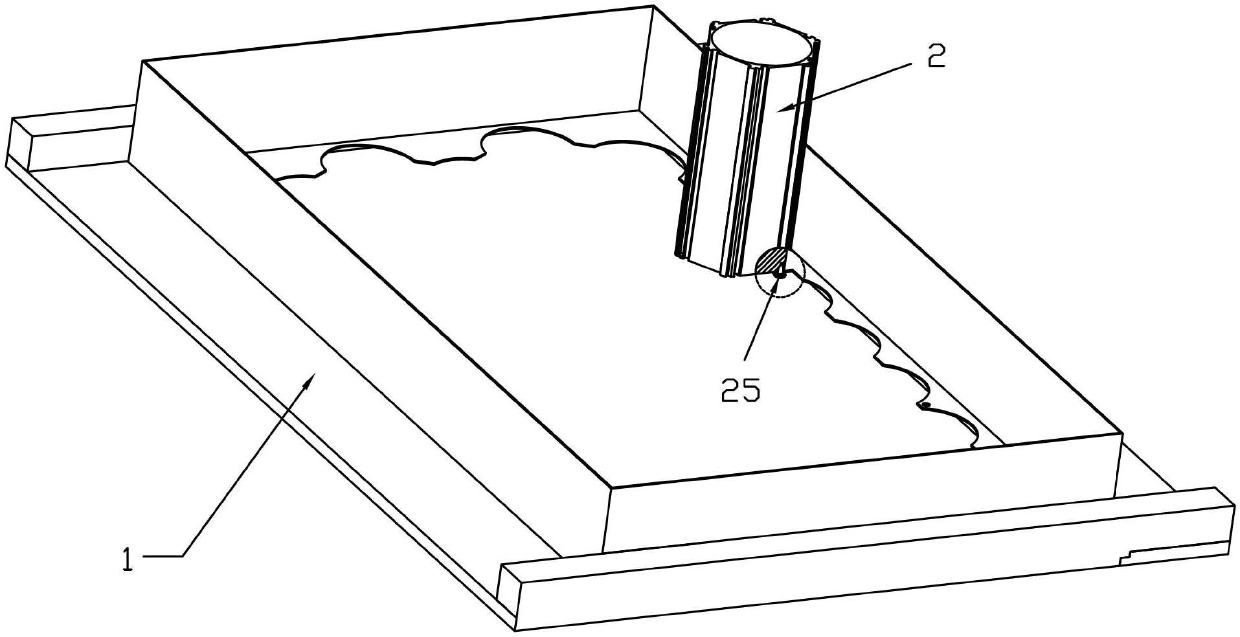

[0017] The positive pole cylinder 2 is installed at the lower position of the positive and negative pole plates 6 and 7 on the insulating box body 1, the insulating box body 1 has no bottom cover, the positive pole cylinder 2 is fixed on the insulating box body 1 by screws 25, the positive pole cylinder 2 A negative electrode rod 3 runs through the middle, and a support p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com