Method for measuring center thickness of reflective confocal lens

A technology of central thickness and confocal lens, which is applied in the direction of measuring devices, instruments, and optical devices, etc., can solve the problems of complex installation and adjustment process, and achieve the effect of reducing complexity, reducing the difficulty of installation and adjustment, and achieving tomographic capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

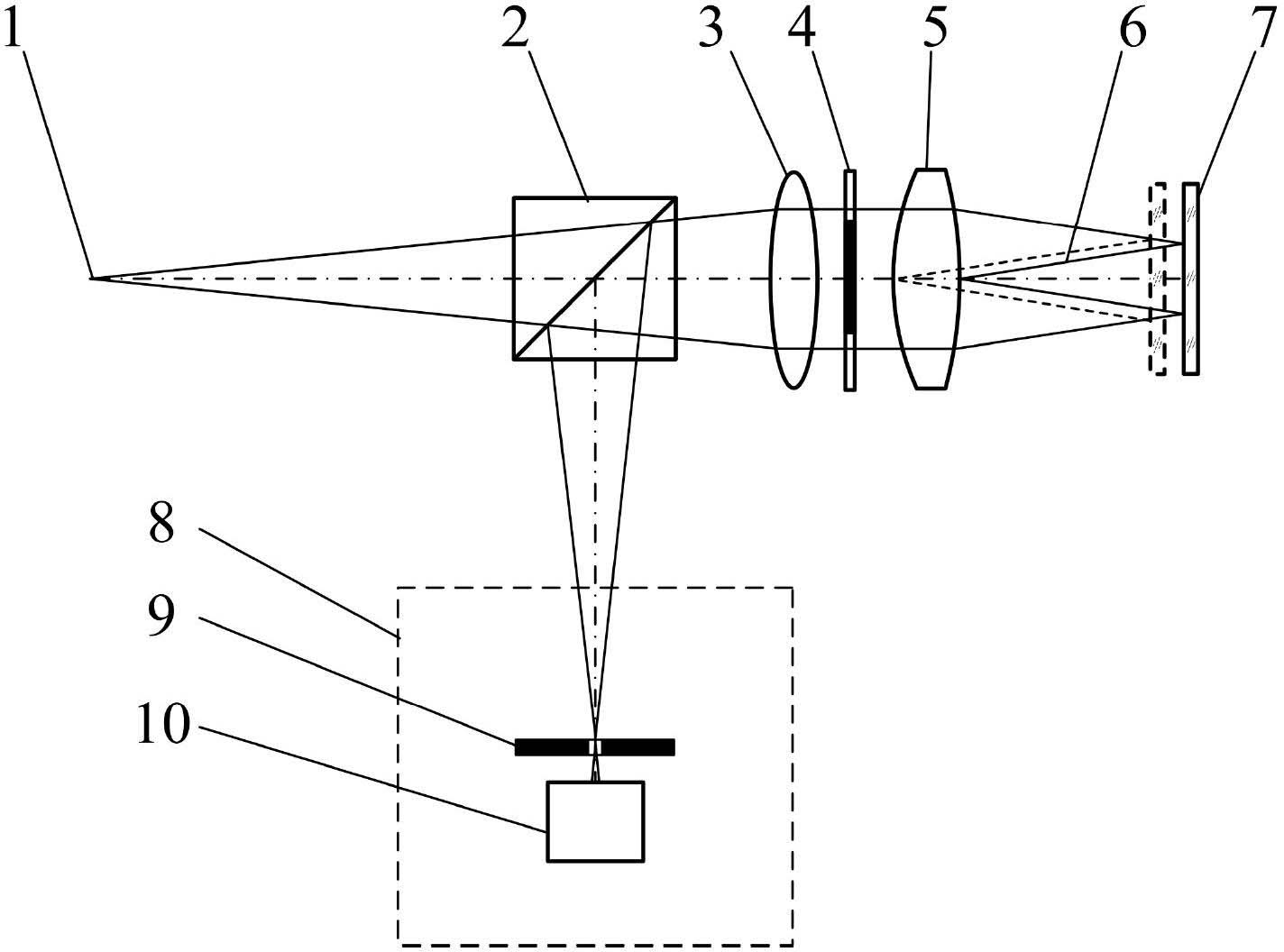

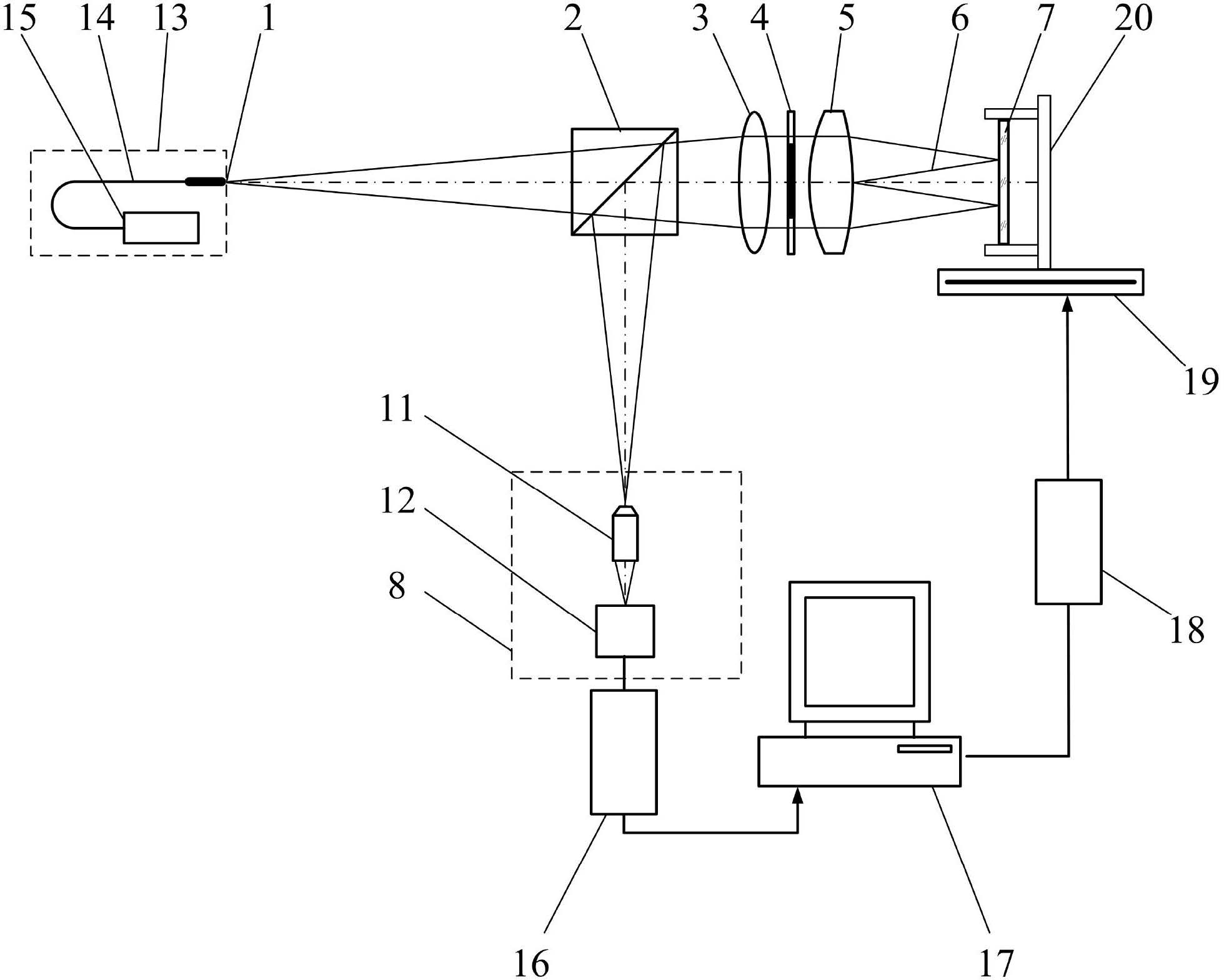

[0042] as attached figure 1 And attached figure 2 As shown, the measurement method for the central thickness of the reflective confocal lens, the measurement steps are:

[0043] (a) Start the measurement software in the main control computer 17, and input relevant parameters, which mainly include the radius of curvature r of the rear surface of the measured lens 5 2 =100.7134mm, air refractive index n 0 =1, the measured lens 5 refractive index n=1.5143 and the numerical aperture angle α of the measuring beam 6 0 =5.8°.

[0044] (b) Turn on the laser 15 , the light emitted by the laser 15 is transmitted through the optical fiber 14 to form the point light source 1 . The light emitted by the point light source 1 passes through the beam splitter 2 and the collimator lens 3 to form a parallel beam;

[0045] (c) Place the plane mirror 7 on the two-dimensional adjustment frame 20, adjust the plane mirror 7 through the two-dimensional adjustment frame 20, so that its surface is...

Embodiment 2

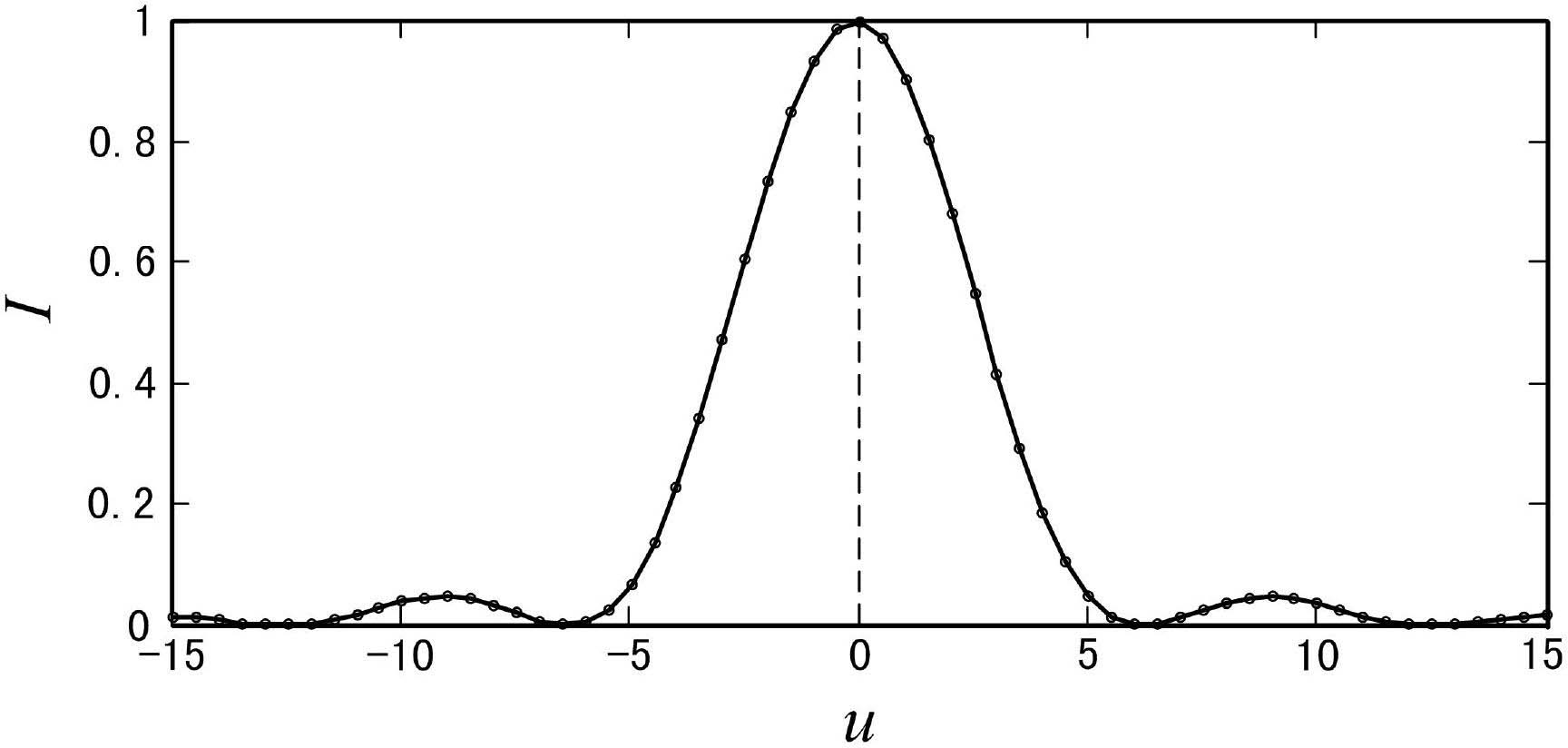

[0054] The difference from Embodiment 1 is that the annular pupil 4 is added to block the paraxial light in the method of measuring the central thickness of the reflective confocal lens, and then the measurement of the central thickness of the measured lens 5 is completed. Due to the addition of the annular pupil 4, the measurement beam 6 forms a hollow measurement light cone, which will effectively reduce the influence of aberrations on the measurement results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com