Method and device for measuring hydraulic characteristic of trickle irrigation emitter

A technology for hydraulic characteristics and measuring devices, which is applied in the directions of measuring devices, testing of machine/structural components, instruments, etc., can solve the problems of long time-consuming, cumbersome testing process, and low efficiency in measuring hydraulic characteristics of irrigators. Measuring efficiency, cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

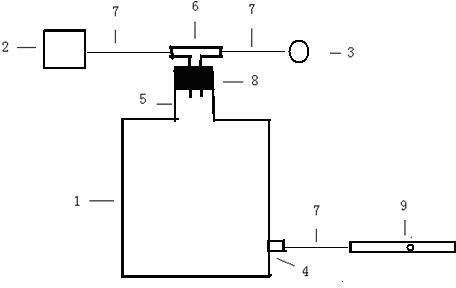

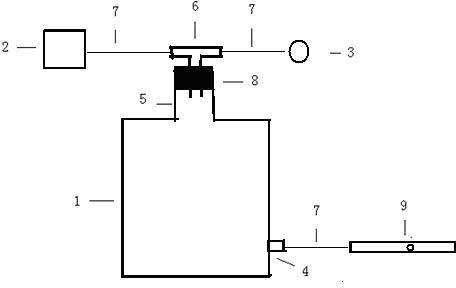

[0030] Example 1, see figure 1 , select the air chamber 1 made of hard plastic or metal to provide gas storage space, connect the gas outlet nozzle 4 at the lower end of the air chamber 1 with the water dispenser 9 to be tested through the connecting hose 7; then connect the air inlet at the upper end of the air chamber 1 The air nozzle 5 is equipped with a rubber plug 8, and a branch of the three-way 6 is connected to the air chamber 1 through the rubber plug 8, and then the other two branches of the three-way 6 are respectively connected to the air supply source 2 and the air supply source 2 through the connecting hose 7. The air pressure gauge 3 is connected, the gas supply source 2 is used to provide air flow to the air chamber 1, and the air pressure gauge 3 is used to measure the gas pressure in the air chamber 1; thereby forming the drip irrigation emitter hydraulic characteristic measuring device of the present invention.

Embodiment 2

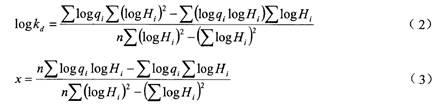

[0031] Embodiment 2, adopt the device of above-mentioned embodiment, carry out drip irrigation emitter hydraulic characteristic measurement, its measuring method is as follows: the emitter hydraulic characteristic measuring device according to figure 1 The method shown is connected to the emitter to be tested, and the air supply source is used to supply air to the air chamber. When the pressure in the air chamber measured by the barometer reaches the predetermined value P (0), the air supply is stopped. The predetermined value P (0) is 20-100cmH 2 The pressure of O, that is, 1.96kPa-9.81kPa; stop the air supply and start timing at the same time, and observe the change of the air chamber pressure measured by the barometer, and record the change process of the air chamber pressure P(t) according to the principle of first sparse and then dense. The cumulative time t of the air chamber, when the pressure in the air chamber is close to the atmospheric pressure, the observation is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com