Method and system for detecting composite insulator interface

A technology for composite insulators and detection methods, which is applied in the field of detection methods and systems for composite insulator interfaces, can solve problems such as high detection costs, low detection efficiency, and inability to identify debonding defects at the interface between sheath and mandrel, and achieve The effect of improving detection efficiency, good conductivity, and reducing detection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

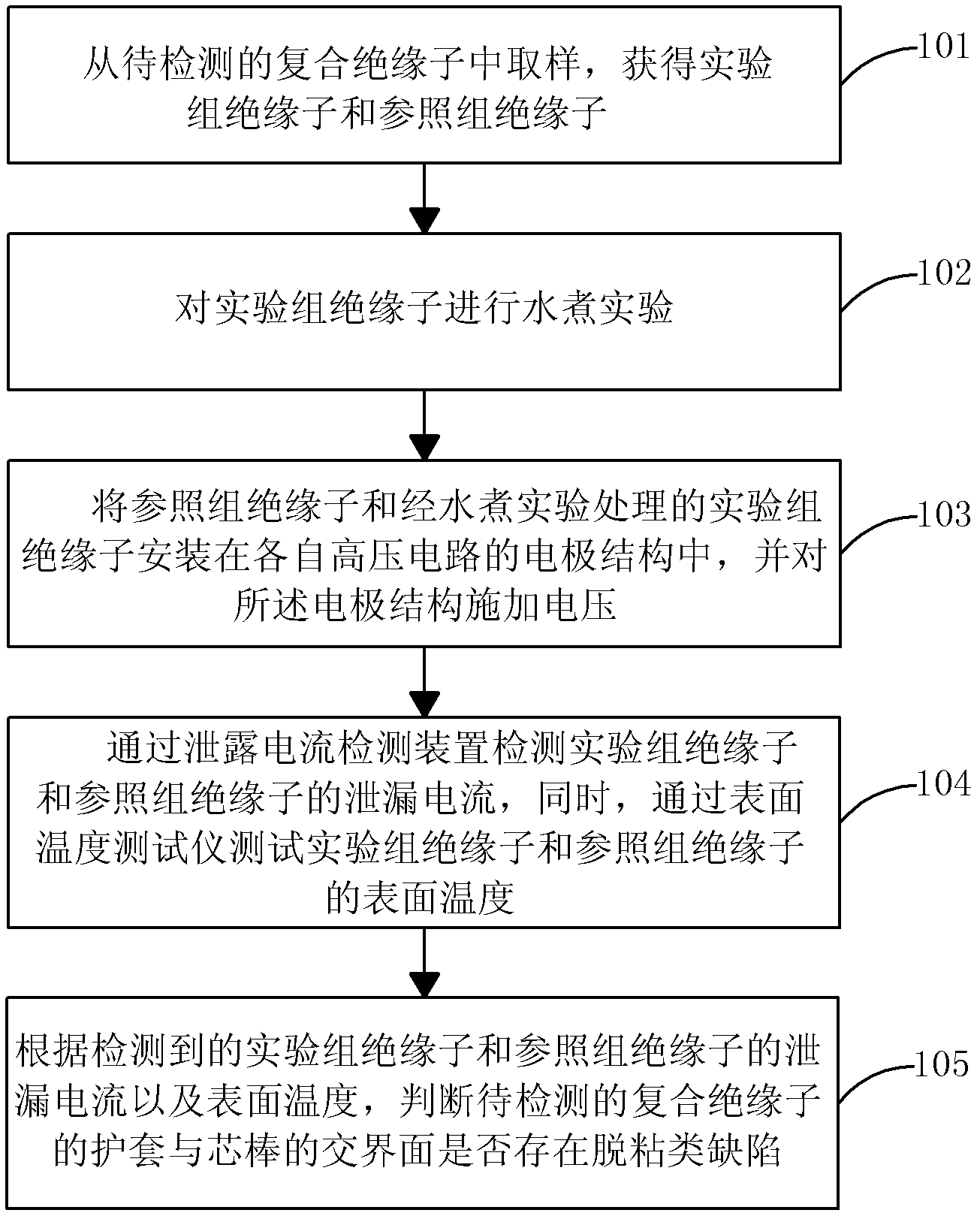

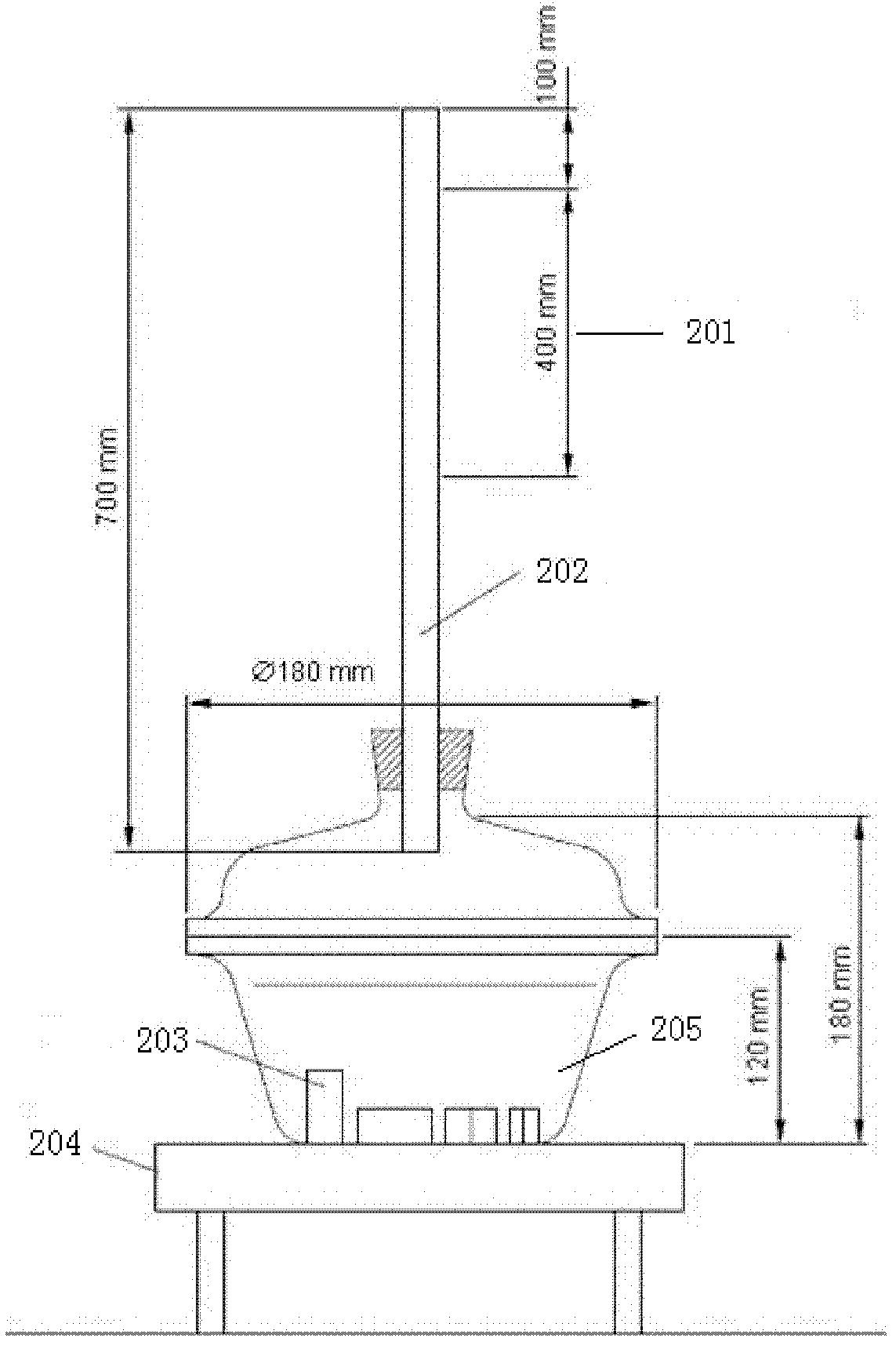

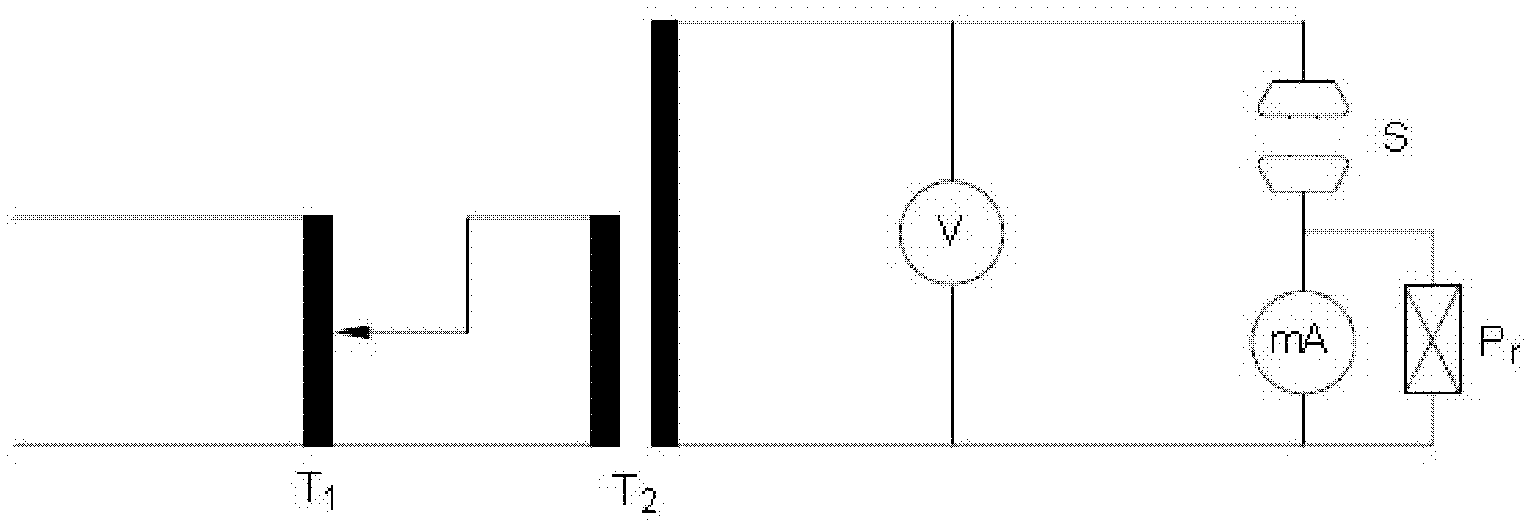

[0036] There are many defects at the interface of composite insulators, but there is no specific detection method for the debonding defect at the interface between the sheath and the mandrel, that is, the defect of the bonding quality at the interface between the sheath and the mandrel. The invention provides a method for detecting debonding defects at the interface between the sheath and mandrel of a composite insulator. During the experiment, the debonding defects will become more obvious, there will be moisture intrusion in the defect, and the conductivity of the material will increase. At this time, a gradually rising voltage is applied to the composite insulator, and the current density at the defect will increase. Then the leakage current will increas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com