Method and system for scheduling production of small-scale steel mill

A technology for production scheduling and rolling mills, applied in the field of production scheduling methods and production scheduling systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] In order to have a clearer understanding of the technical features, purposes and effects of the invention, the specific implementation of the invention will now be described with reference to the accompanying drawings.

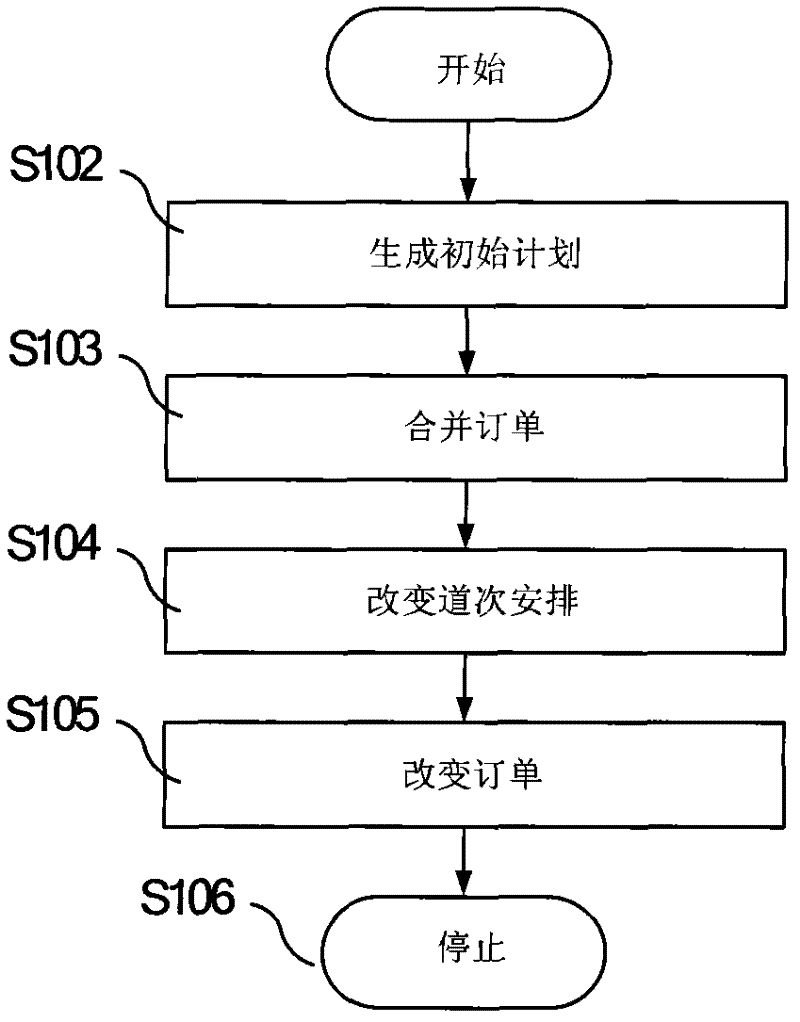

[0082] figure 1 A schematic flow of the production scheduling method for a small rolling mill is shown.

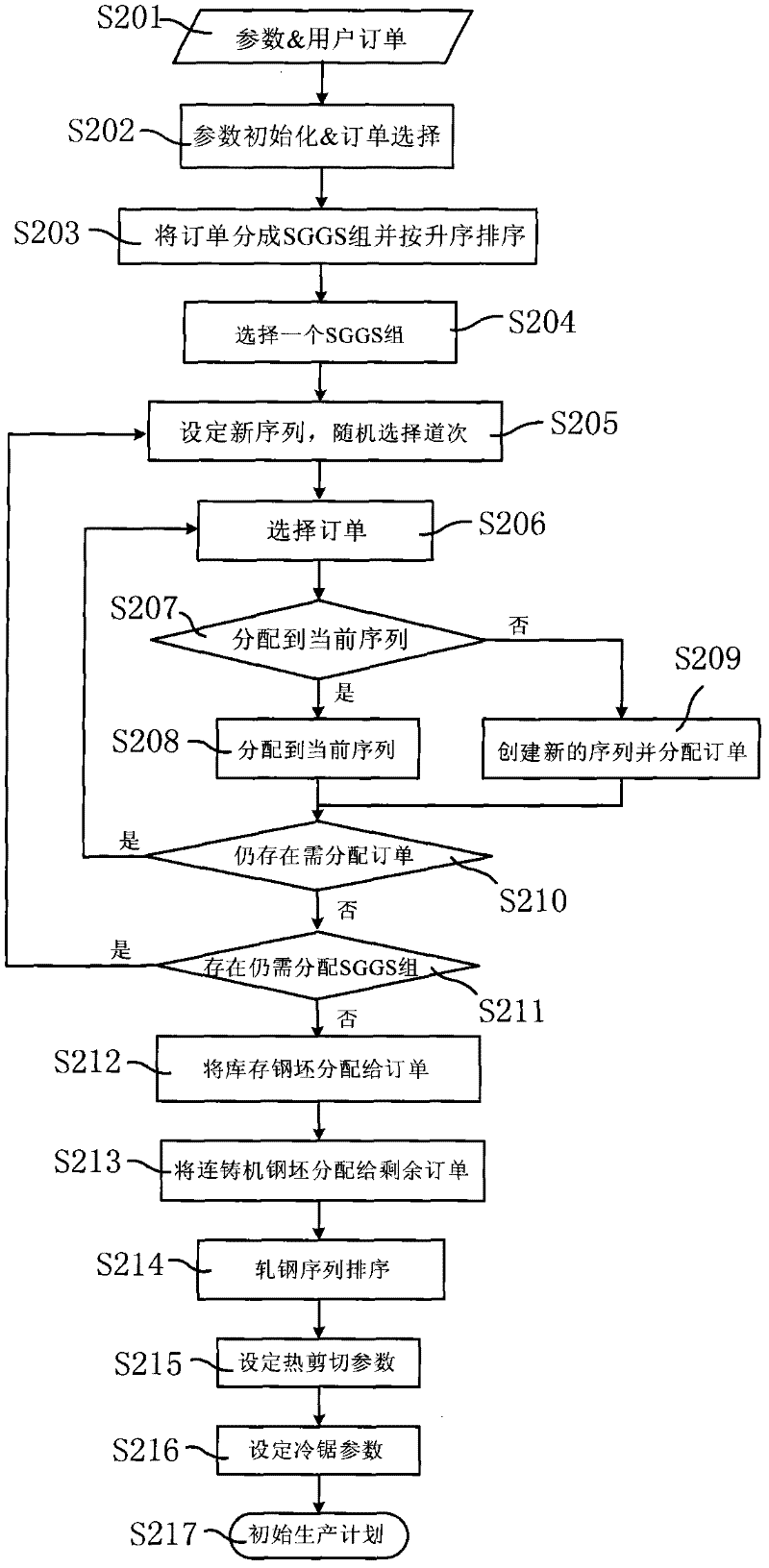

[0083] At step S102, according to the steel type and product size code, the customer order is assigned to a corresponding sequence and a randomly selected pass, thereby generating an initial production plan.

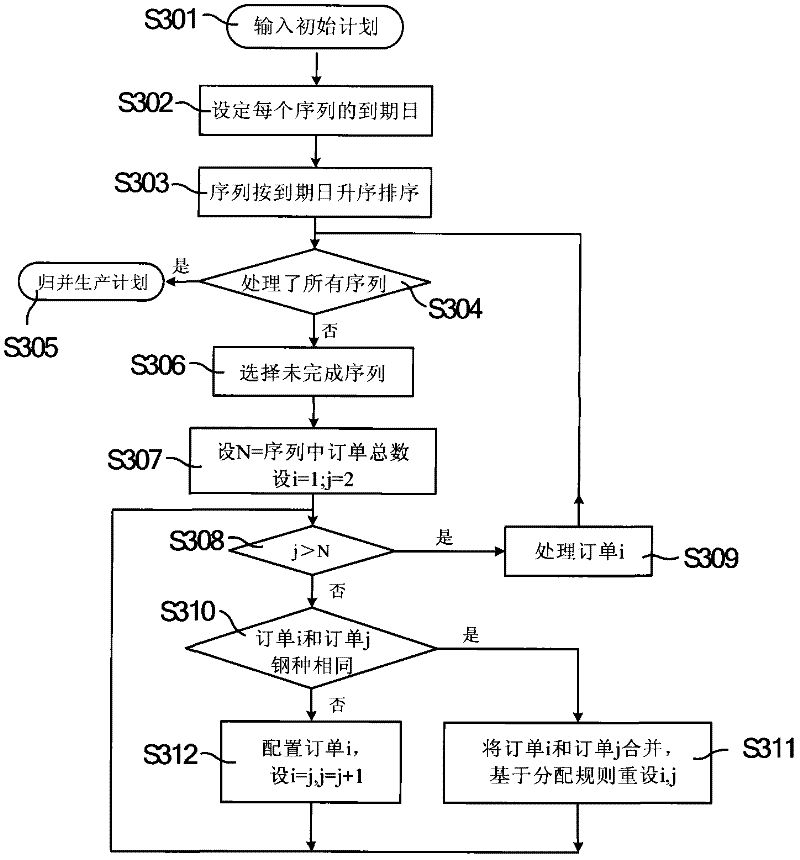

[0084] In step S103, the rolling sequences in the initial production plan formed in step S102 are sorted according to the delivery date, and two orders with the same steel type group are combined and allocated to one billet according to the merging algorithm, and the processed The rolling sequence is generated to generate a consolidated production plan.

[0085] In step S104, when the corresponding total output rate of the merged production ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com