Permanent-magnet rotor with embedded magnetic steels

A technology of permanent magnet rotor and magnet steel, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problem of unreliable axial fixation of magnet steel, rotor can not produce air convection, and the consumption of electromagnetic materials increases and other problems, to achieve the effect of reliable axial fixation of magnetic steel, simple and reasonable structure, and reduced consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

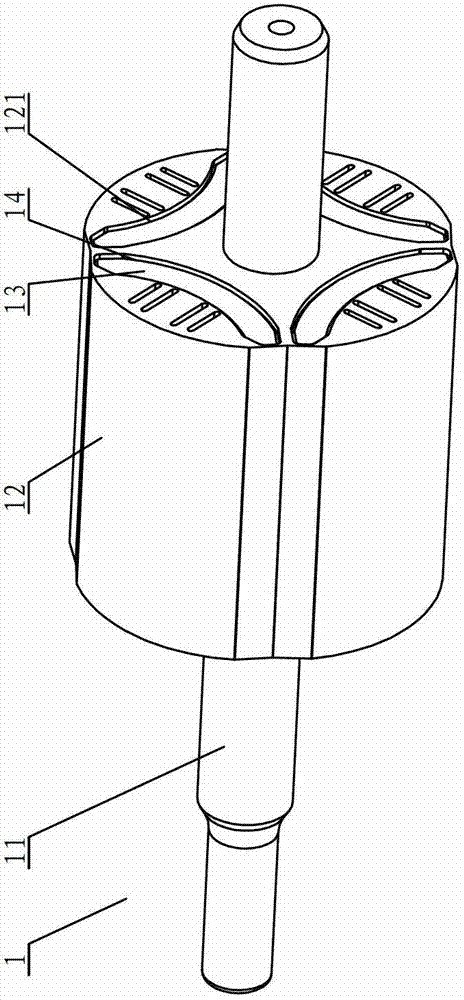

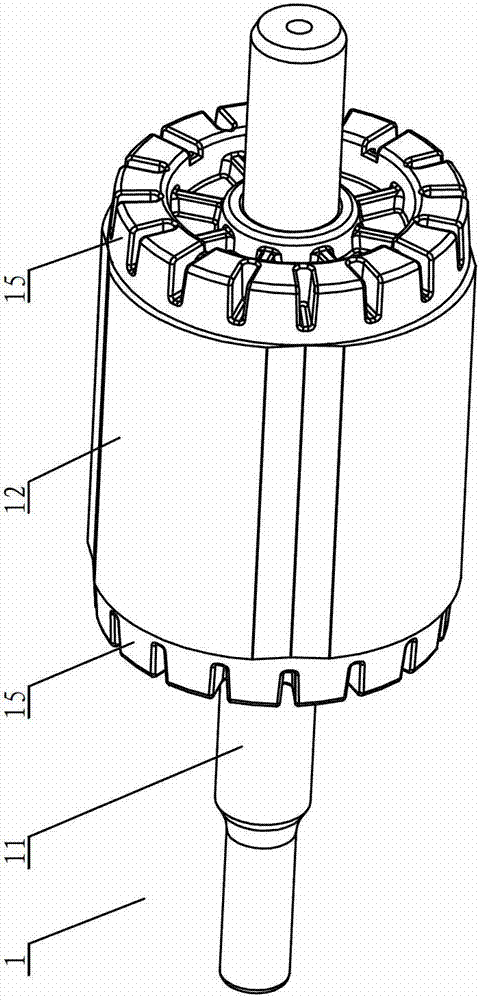

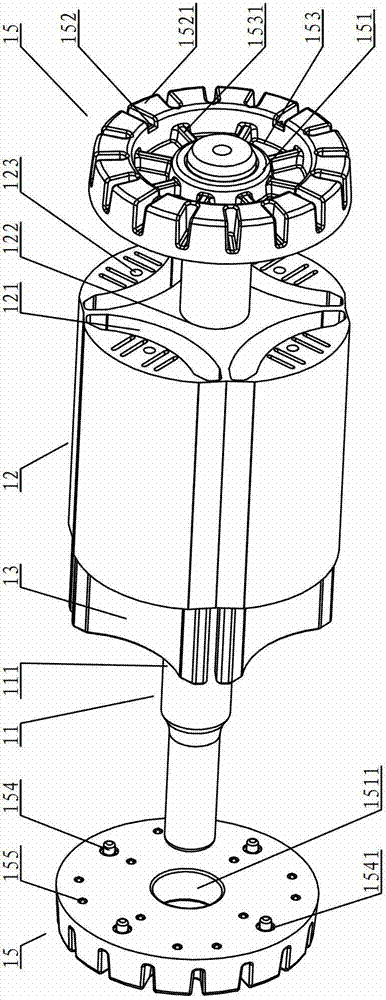

[0026] see Figure 2-Figure 3 , the permanent magnet rotor embedded in the magnetic steel includes a rotor core 12 sleeved on the rotor shaft 11, the magnetic steel 13 is inserted on the rotor core 12, and the rotor core 12 is provided with a sleeve sleeved on the rotor shaft. 11 on the balance ring 15, the balance ring 15 is made of non-magnetic material. In this embodiment, there are two balance rings 15 , which are respectively arranged on the two sides of the rotor core 12 .

[0027] One side of the balance ring 15 is provided with an inner ring 151 and an outer ring 152 , the inner ring 151 and the outer ring 152 are connected by more than two reinforcing ribs 1531 , and counterbores 153 are arranged between adjacent reinforcing ribs 1531 . The ribs 1531 are evenly arranged. In this embodiment, the number of reinforcing ribs 1531 may be 3-15, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com