Heat treatment method of porous copper-aluminum-manganese shape memory alloy

A heat treatment method and memory alloy technology, which is applied in the field of heat treatment of porous copper-aluminum-manganese shape memory alloys, can solve the problems of copper-based shape memory alloys such as the decline in damping performance, achieve good comprehensive performance, and improve the effect of comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

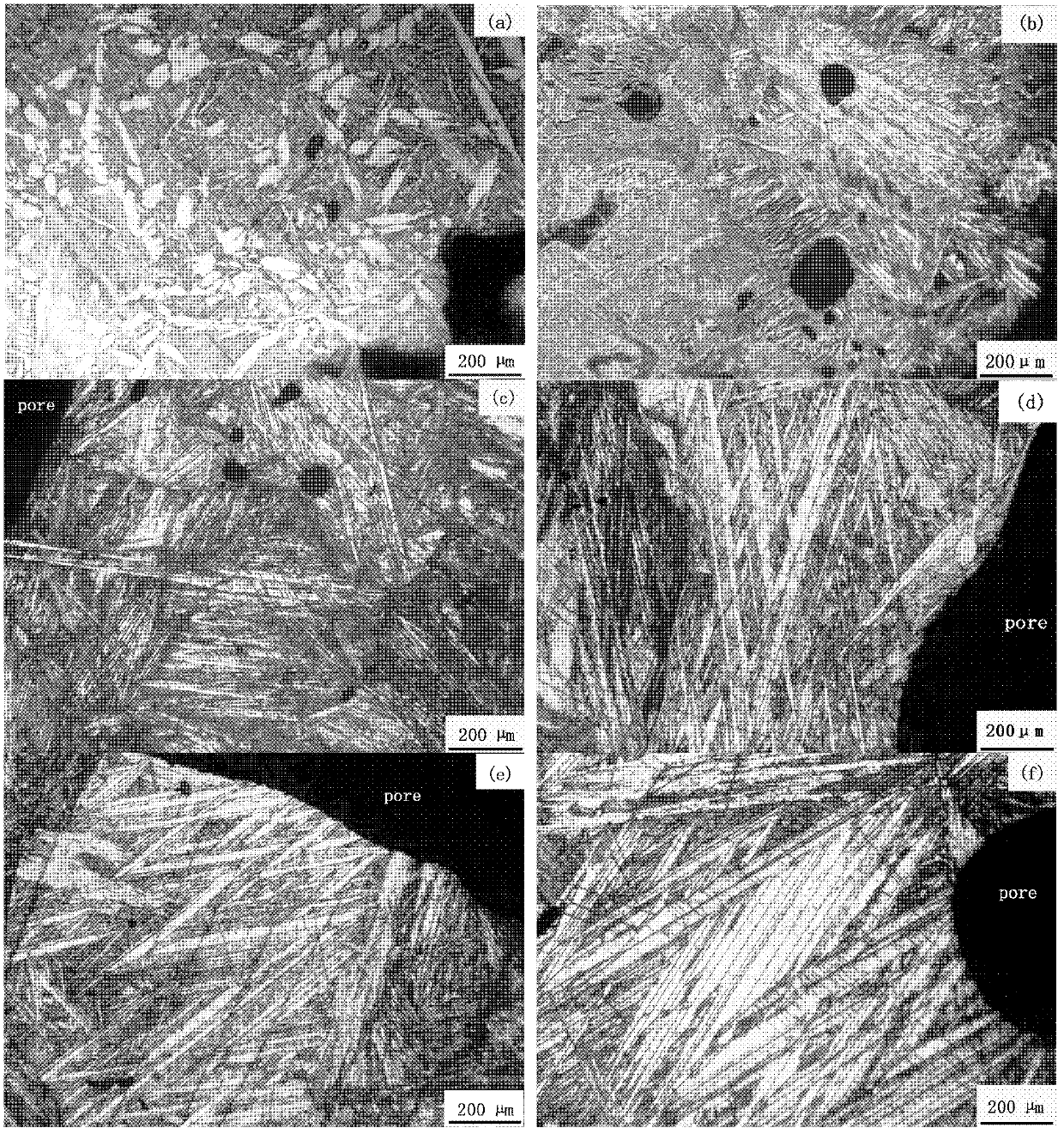

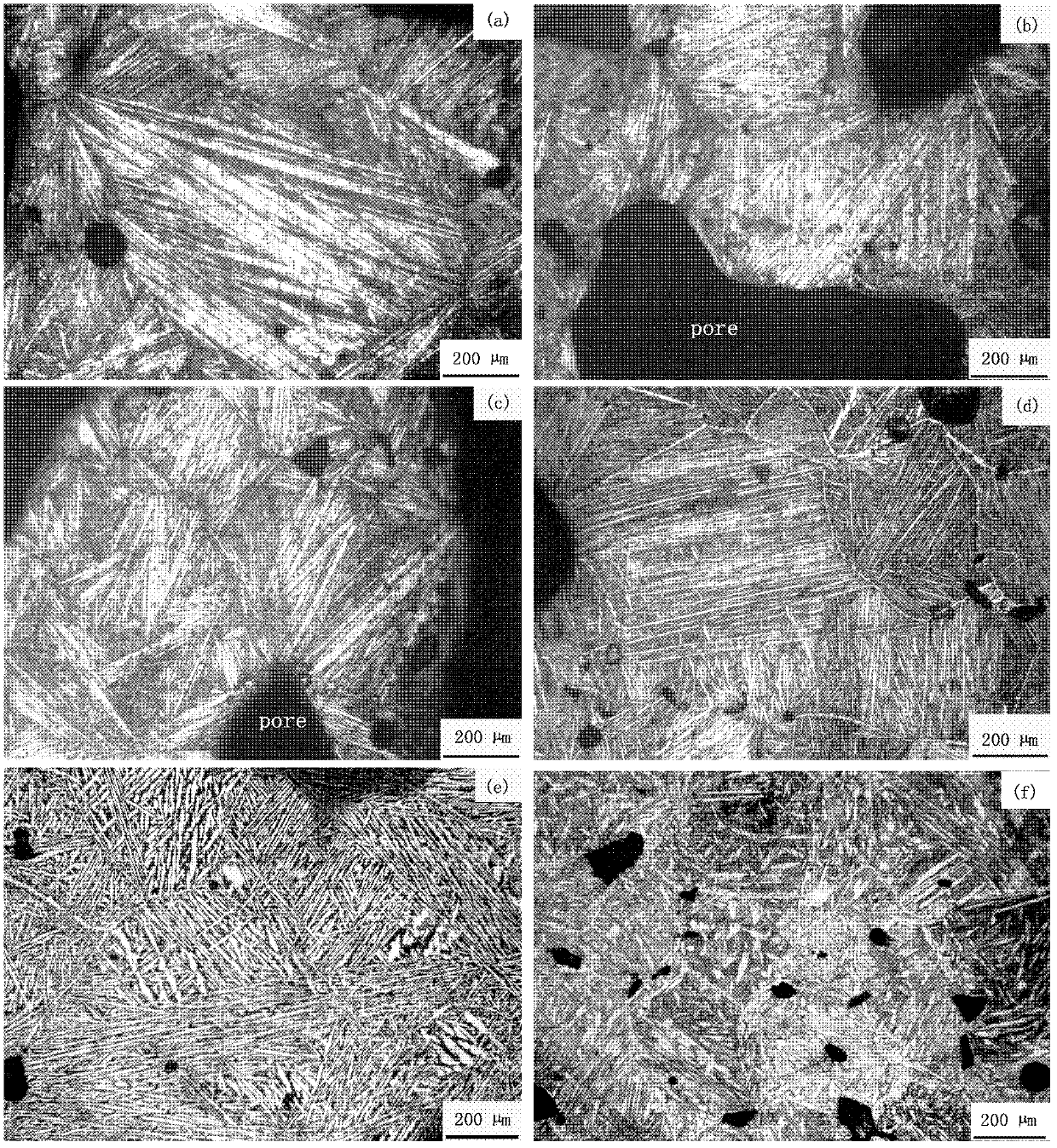

Image

Examples

Embodiment 1

[0042] The first step, solution treatment of porous copper-aluminum-manganese shape memory alloy

[0043] The porous copper-aluminum-manganese shape memory alloy prepared by sintering-desolventization process is placed in a tubular vacuum / atmosphere furnace, and high-purity argon is firstly circulated at a large flow rate for 5 minutes to expel the furnace tube and porous copper-aluminum-manganese shape memory After that, the air in the alloy cells starts to heat up, and at the same time, the high-purity argon flow rate is reduced, and the heat preservation is carried out after the temperature rises to 850°C, so as to ensure that the porous copper-aluminum-manganese shape memory alloy prepared by the sintering-desolventization process is The solid solution time of mm effective thickness is 500 seconds;

[0044] The second step, quenching treatment of porous copper-aluminum-manganese shape memory alloy

[0045] After the solid solution treatment of the porous copper-aluminum-m...

Embodiment 2

[0052] The first step, solution treatment of porous copper-aluminum-manganese shape memory alloy

[0053] The porous copper-aluminum-manganese shape memory alloy prepared by sintering-desolventization process is placed in a tubular vacuum / atmosphere furnace, and high-purity argon is firstly circulated at a large flow rate for 5 minutes to expel the furnace tube and porous copper-aluminum-manganese shape memory The air in the alloy cells starts to heat up, and at the same time, the flow rate of high-purity argon gas is reduced, and the heat preservation is carried out after the temperature rises to 870°C, so as to ensure that the porous copper-aluminum-manganese shape memory alloy prepared by the sintering-desolventization process is The solid solution time of mm effective thickness is 480 seconds;

[0054] The second step, quenching treatment of porous copper-aluminum-manganese shape memory alloy

[0055] After the solid solution treatment of the porous copper-aluminum-mangan...

Embodiment 3

[0061] The first step, solution treatment of porous copper-aluminum-manganese shape memory alloy

[0062] The porous copper-aluminum-manganese shape memory alloy prepared by sintering-desolventization process is placed in a tubular vacuum / atmosphere furnace, and high-purity argon is firstly circulated at a large flow rate for 5 minutes to expel the furnace tube and porous copper-aluminum-manganese shape memory After that, the air in the alloy cells starts to heat up, and at the same time, the high-purity argon flow rate is reduced, and the heat preservation is carried out after the temperature rises to 900°C, so as to ensure that the porous copper-aluminum-manganese shape memory alloy prepared by the sintering-desolventization process is The solid solution time of mm effective thickness is 450 seconds;

[0063] The second step, quenching treatment of porous copper-aluminum-manganese shape memory alloy

[0064] After the solid solution treatment of the porous copper-aluminum-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com