Sterilization process challenge test tube

A technology of test tube and sterilization indicator, which is applied to sanitary equipment, water supply equipment, buildings and other directions for toilets, and can solve the problems of high cost and large volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

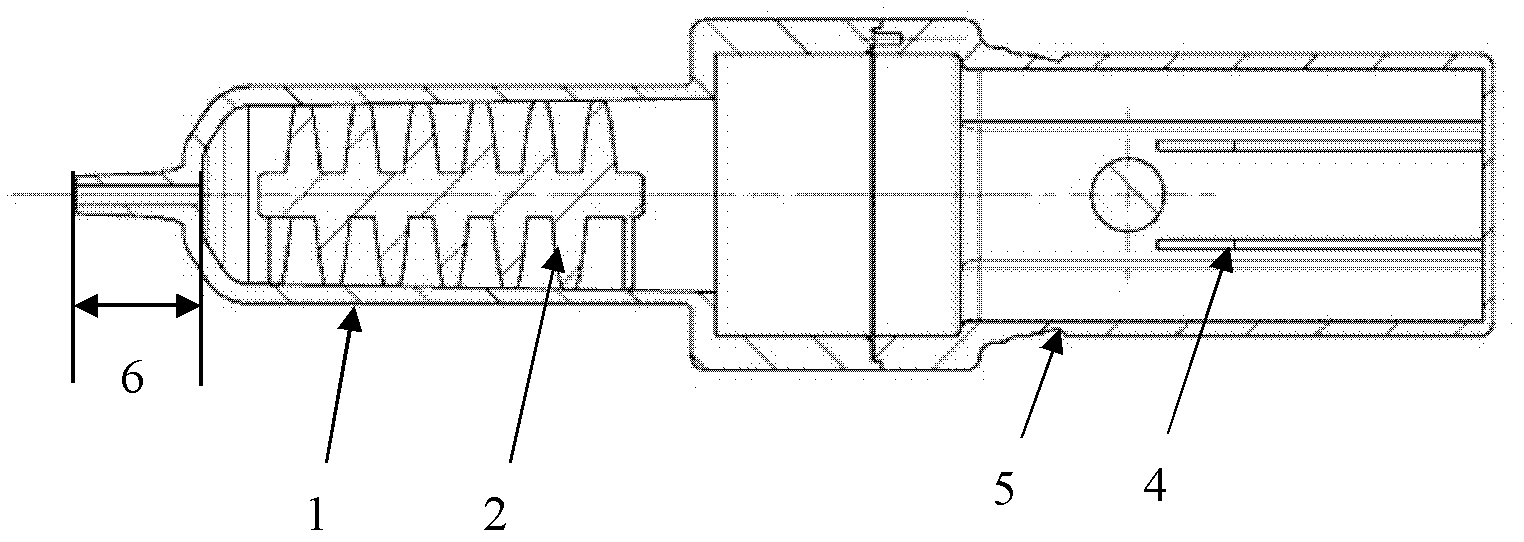

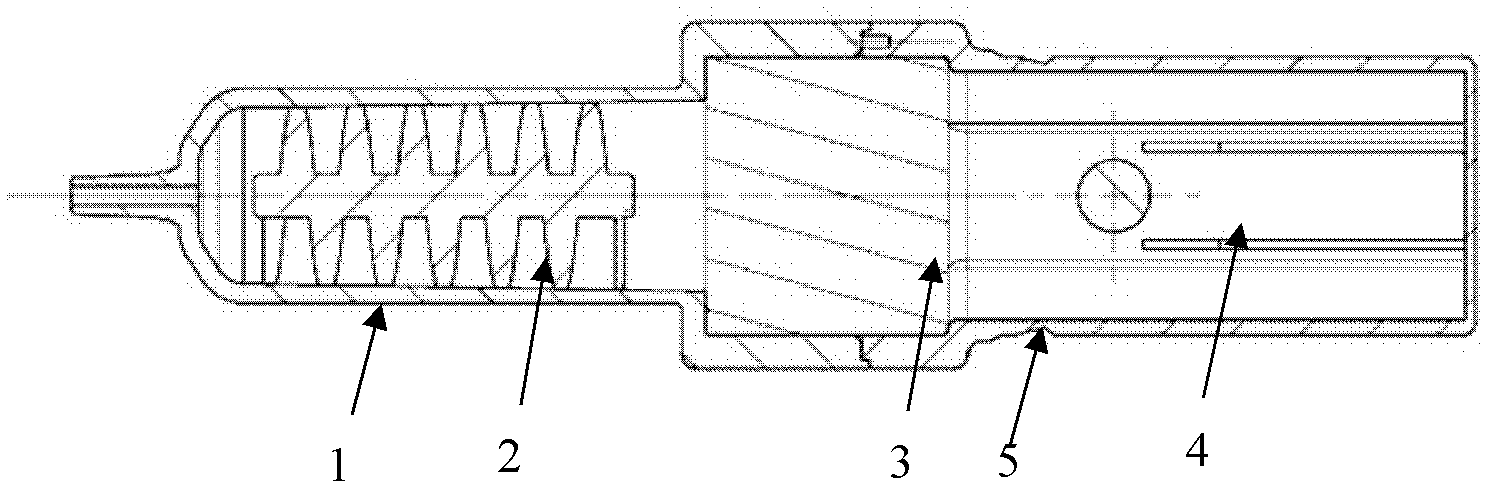

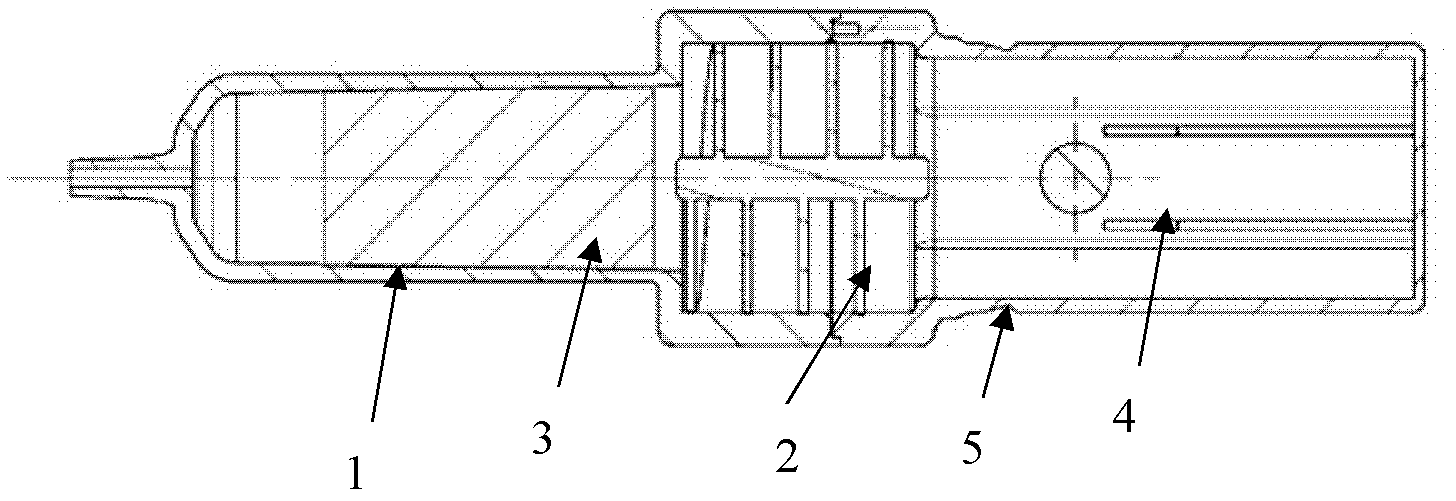

[0079] Example 1: Lumen Process Challenge Test Tubes

[0080] prepared as figure 1 The lumen-type process challenge test tube is shown, wherein the tube body is made of polycarbonate material with a thickness of 3 mm, the length of the cavity where the vapor damping structure is placed is 52 mm, and the inner diameter is 18 mm. The vapor damping structure is in the form of interleaved laminations made of polycarbonate material. Figure 8 It is a schematic diagram of a lamination used in Example 1. The diameter of the lamination is 18mm, and the thickness is 2mm. There are 8 laminations in total. The distance between the laminations is 4mm, and the distance between the open end and the pipe body is 11mm. The inner diameter of the end is 2mm. The cross-section of the laminations is a portion of a circle, wherein the area of the cross-section of the laminations is 75% of the area of the circle. The sterilization indicator is 3M 1243A Class V chemical indicator.

Embodiment 2

[0081] Example 2: Lumen Process Challenge Test Tubes

[0082] The cavity-type process challenge test tube of Example 2 was prepared as in Example 1, except that there were 16 laminations in total, the distance between the laminations was 2 mm, and the length of the cavity for placing the vapor damping structure was 70 mm.

Embodiment 3

[0083] Example 3: Lumen Process Challenge Test Tubes

[0084] The cavity-type process challenge test tube of Example 3 was prepared as in Example 1, except that the cross-sectional area of the laminations was 90% of the circular area.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com