Resin catalyst for light gasoline etherification and preparation method thereof

A catalyst and light gasoline technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve regeneration difficulties, easy loss of active acid components, and low-temperature activity Poor problems, to achieve the effect of enhanced energy non-uniformity, excellent low-temperature reactivity and selectivity, and improved poisoning resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

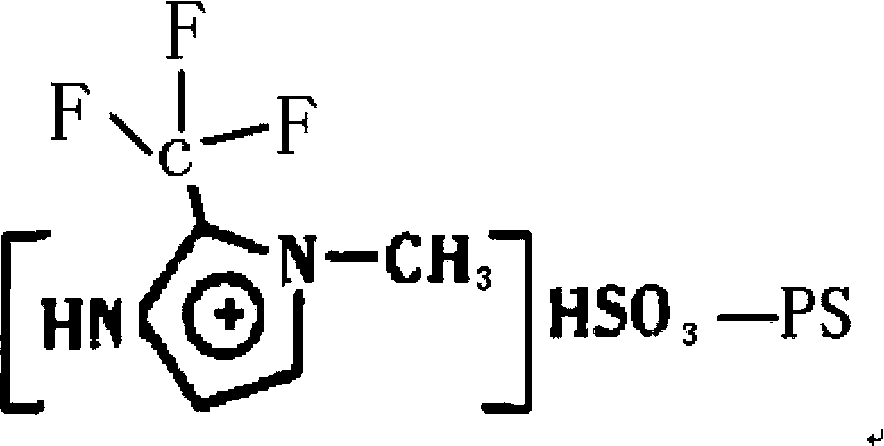

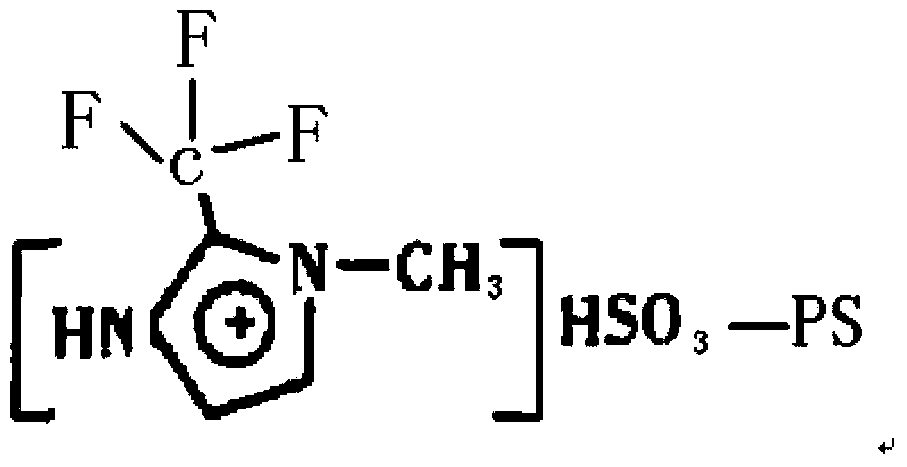

Image

Examples

Embodiment 1

[0029] In the reactor, add 100 parts by weight of D001 strongly acidic macroporous cation exchange resin under stirring, add 200 parts by weight of dehydrated alcohol, add 10 parts by weight of concentrated sulfuric acid of 98% mass concentration, and then add 2 parts by weight of N -Methylimidazole participates in the reaction, and the feeding temperature is controlled at 0°C. After the feeding is completed, the temperature is raised to 45°C, and the reaction is carried out for 4 hours. After the reaction, the product is washed until neutral, and a qualified product is obtained. The resulting product number was KRB-1.

Embodiment 2

[0031] Replace D001 strongly acidic macroporous cation exchange resin with D006 strongly acidic macroporous cation exchange resin, and the others are the same as in Example 1. The resulting product number is KRB-2.

Embodiment 3

[0033] The part by weight that adds the vitriol oil of 98% mass concentration is 20 parts, and other is with embodiment 1. The resulting product number was KRB-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com